Screen-free printing plate of battery piece

A printing plate, no network knot technology, applied to screen printing machines, printing, printing machines, etc., can solve the problems of easy movement of printing motors, low printing quality, inaccurate positioning, etc., to achieve smooth rotation and high printing quality High, uniform printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

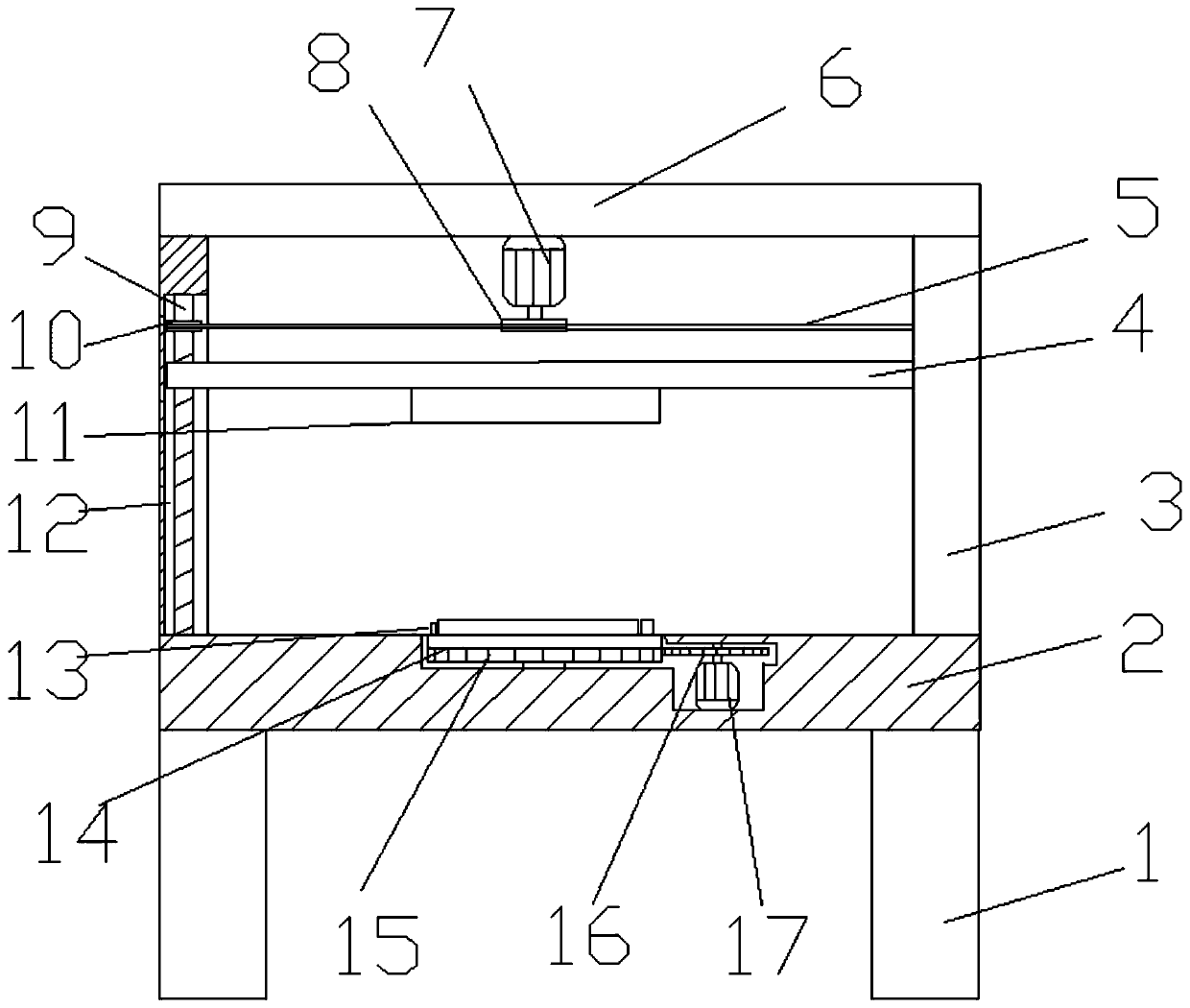

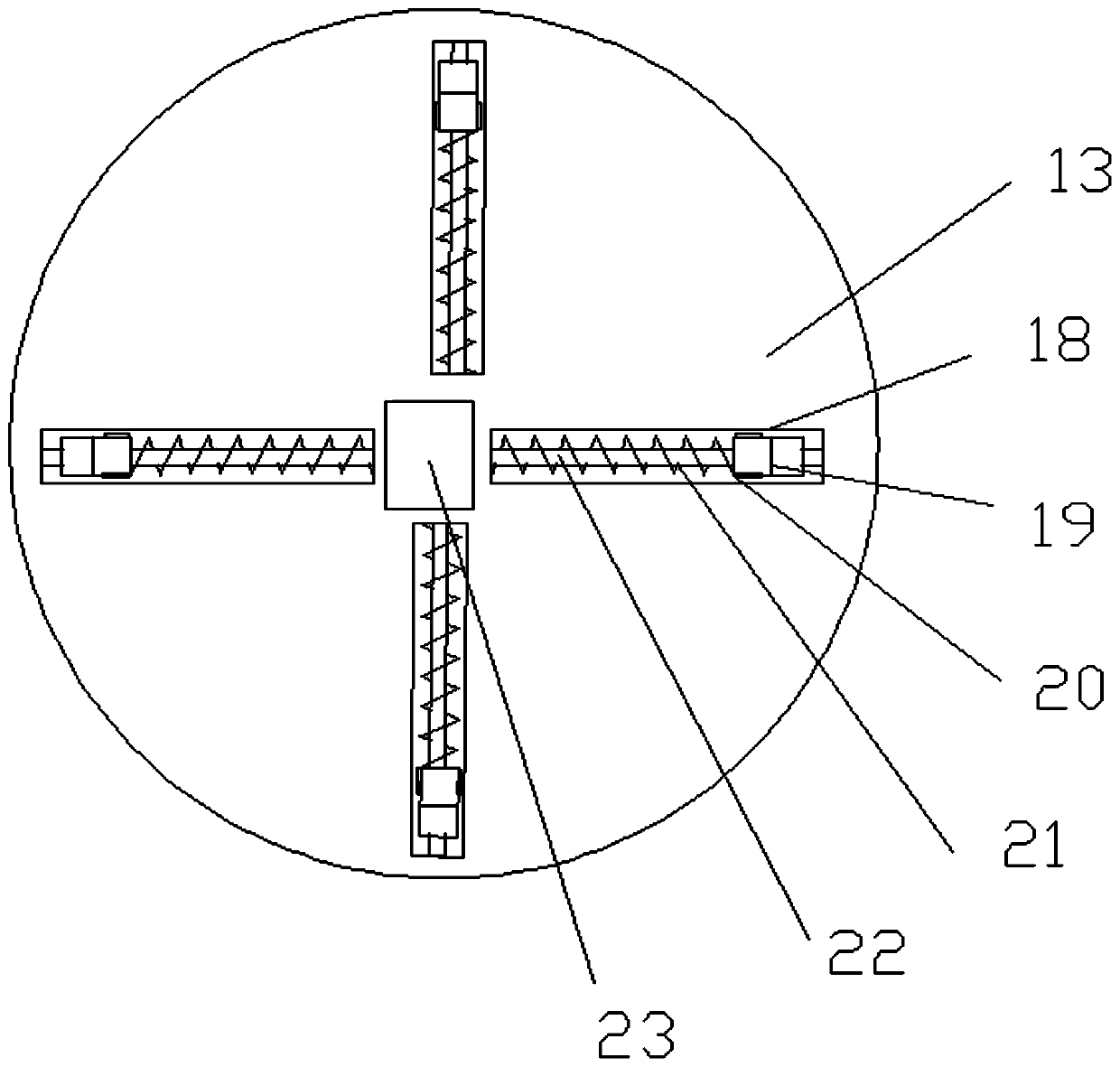

[0021] see Figure 1-2 , a grid-free printing plate of a cell, including a workbench 2 and a main body 11 of the printing plate. The four corners of the lower surface of the workbench 2 are fixed with vertical support legs 1 , and the support legs 1 have a supporting effect on the workbench 2 . The upper surface of the workbench 2 is symmetrically fixed with a vertical column 3 at the left and right ends, the top of the column 3 is connected by a horizontal push rod 6, and the lower surface of the middle position of the push rod 6 is fixedly installed with a first motor 7, the first motor The output shaft of 7 is coaxially connected with driving wheel 8. Driven by the first motor 7 , the drive wheel 8 rotates coaxially with the output shaft of the first motor 7 . The inside of the column 3 is provided with a mounting groove 12, and a vertical screw rod 9 is rotated in the mounting groove 12. The top end of the screw rod 9 is coaxially connected with a driven disc 10, and the...

Embodiment 2

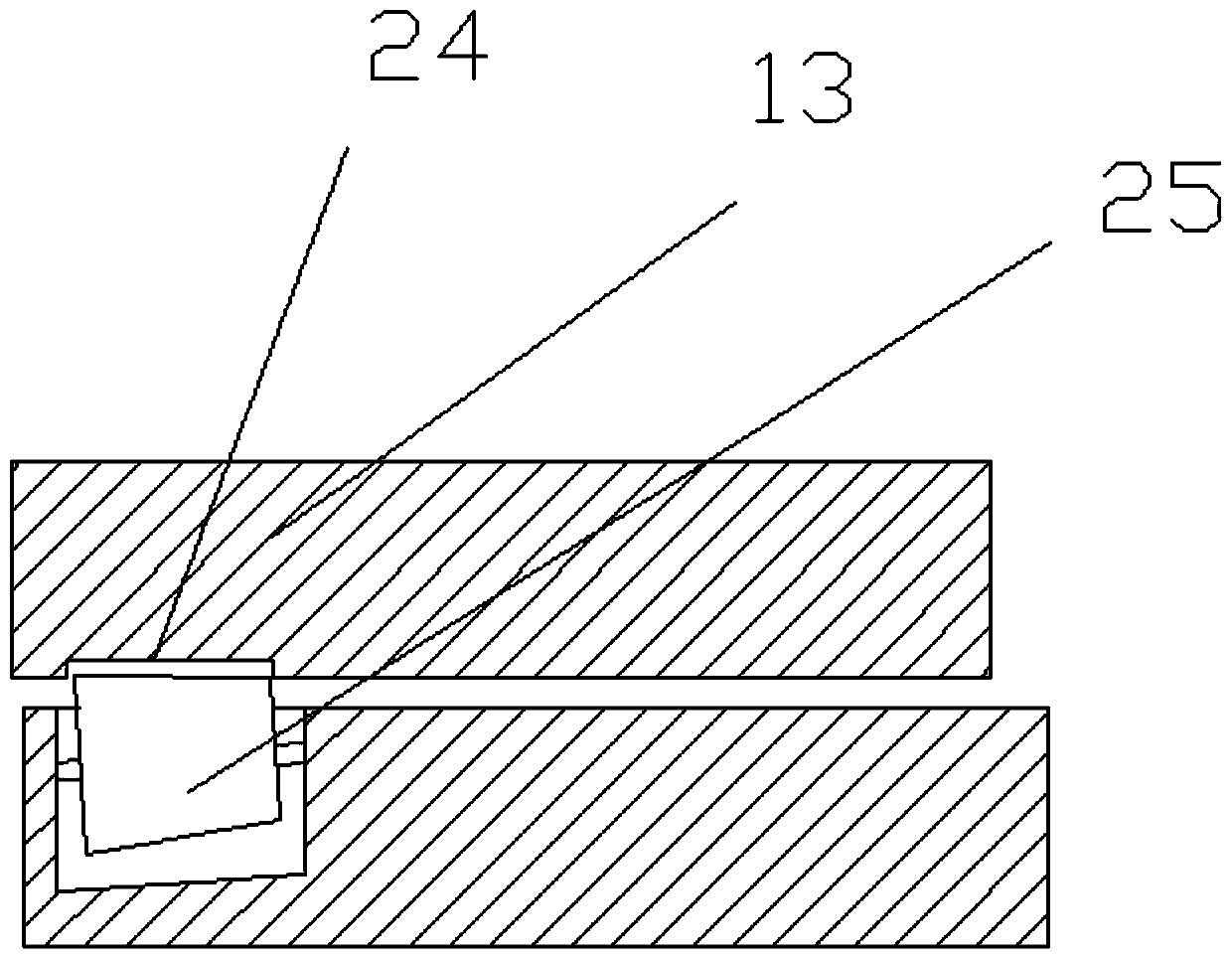

[0025] see image 3 On the basis of Embodiment 1, a circle of rolling grooves 24 is provided at the radial position of the lower surface of the rotating seat 14, and a running wheel 25 is arranged on the upper surface of the workbench 2 below the rolling groove 24, and the running wheels 25 are placed obliquely. Conical structure, the top of the runner 25 is nested inside the rolling groove 24, the runner 25 has a supporting effect on the clamping assembly 13, the setting of the runner 25 makes the rotation of the rotating seat 14 more stable and smooth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com