In-situ preparation and application method for povidone iodine-based antimicrobial micro-nano fiber dressing

A nanofiber, in-situ preparation technology, used in fiber treatment, medical science, absorbent pads, etc., can solve the problems of difficulty in fitting the fibrous membrane dressing to the wound surface, secondary wound damage, etc., achieving good antibacterial effect and reducing irritation. , the effect of good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

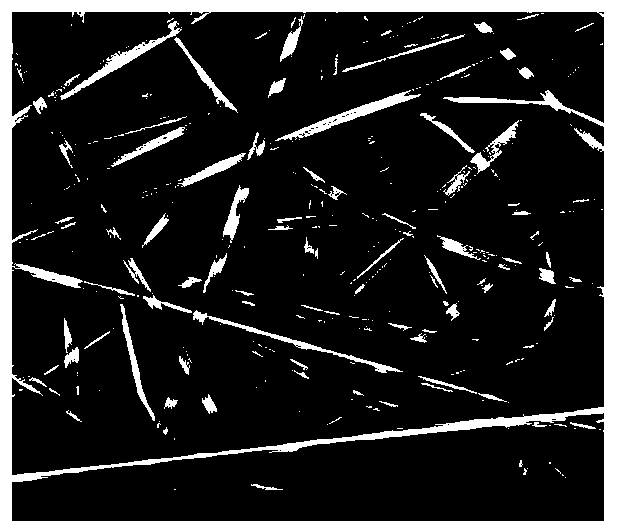

Image

Examples

Embodiment 1

[0017] Step 1: Take by weighing 1.5 grams of polyvinylpyrrolidone powder (PVP, molecular weight 1.3 million), all dissolved in 8.5 grams of absolute ethanol, magnetically stirred at room temperature for 8 hours until completely dissolved, to obtain a uniform PVP spinning with a solute mass fraction of 15 wt%. silk precursor;

[0018] Step 2: Weigh 1.0 gram of iodine elemental substance and dissolve it in 9.0 gram of absolute ethanol, stir magnetically at room temperature for 2 hours until completely dissolved, and obtain a uniform iodine solution with a solute mass fraction of 10 wt %;

[0019] Step 3: Add the iodine solution prepared in step 2 to the spinning precursor solution prepared in step 1, the amount added makes the mass percentage of iodine simple substance in the solution 5%, stir for 2 hours, and make it mix uniformly , after standing still for 2 hours, a uniform and stable spinning precursor solution was obtained;

[0020] Step 4: Add the spinning precursor solut...

Embodiment 2

[0023] Step 1: Take 1.0 gram of polyvinyl butyral (PVB, molecular weight is 90000), dissolve it completely in 9.0 gram of absolute ethanol, stir magnetically at room temperature for 8 hours until completely dissolved, and obtain a homogeneous solution with a solute mass fraction of 10 wt%. PVB solution;

[0024] Step 2: Take 1.0 gram of polyvinylpyrrolidone iodine (PVPI, molecular weight is 10000-40000), all dissolved in 9.0 gram of absolute ethanol, magnetically stirred at room temperature for 8 hours until completely dissolved, to obtain a solute mass fraction of 10wt% Uniform PVPI solution (iodine);

[0025] Step 3: the PVPI iodophor solution prepared in step 2 is added to the PVB solution prepared in step 1, the amount added makes the mass percentage of PVPI in the solution be 5%, stir for 2 hours, make it mix uniformly, and then After standing for 2 hours, a uniform and stable spinning precursor solution was obtained;

[0026] Step 4: Add the spinning precursor solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Dimension diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com