Intelligent fault detection method for acquisition operation and maintenance system

A technology of fault detection, operation and maintenance system, applied in the fields of digital data information retrieval, resources, instruments, etc., can solve the problems of complexity, large number, and high operation and maintenance workload, and achieve stable judgment threshold and high detection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, an intelligent fault detection method for a collection operation and maintenance system provided by the present invention will be described in detail below with reference to the drawings and specific embodiments.

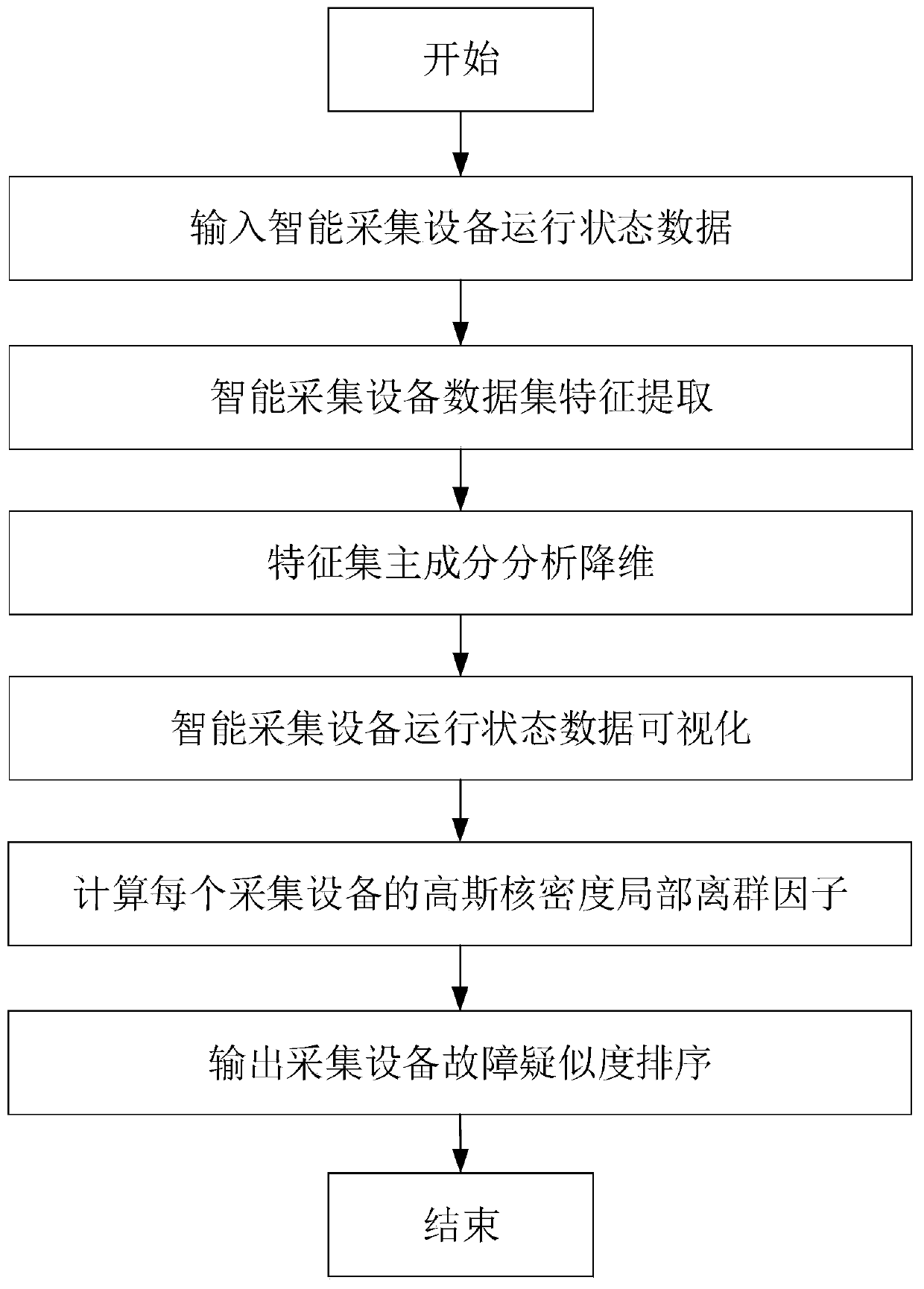

[0034] Such as figure 1 As shown, a method for intelligent fault detection of a collection operation and maintenance system provided by the present invention includes the following steps performed in order:

[0035] Step (1) input the operating status data of the intelligent acquisition equipment;

[0036] Step (2) feature extraction of intelligent collection equipment dataset;

[0037] Step (3) feature set principal component analysis dimensionality reduction;

[0038] Step (4) Visualization of the operating state data of the intelligent acquisition equipment;

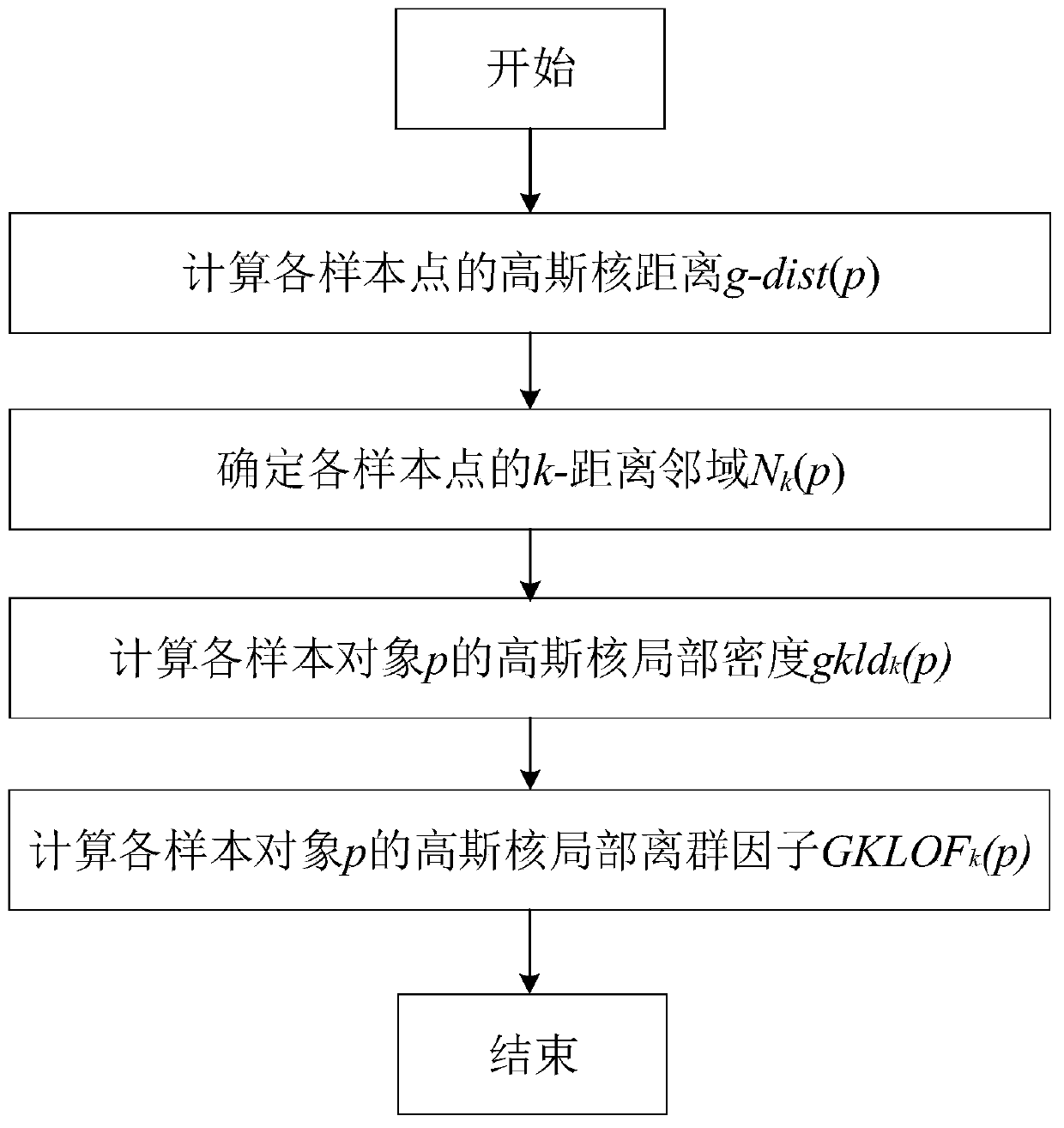

[0039] Step (5) calculates the Gaussian kernel density local outlier fact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com