A novel re-feeding device for Czochralski grown monocrystalline and an operating method thereof

A single crystal, a new type of technology, applied in the direction of chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of increasing the impact force of the quartz umbrella, reducing the quality of crystal pulling, and the decline of single crystal quality, so as to improve the quality of single crystal Effects of silicon quality, improvement of silicon single crystal quality, and reduction of interstitial oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

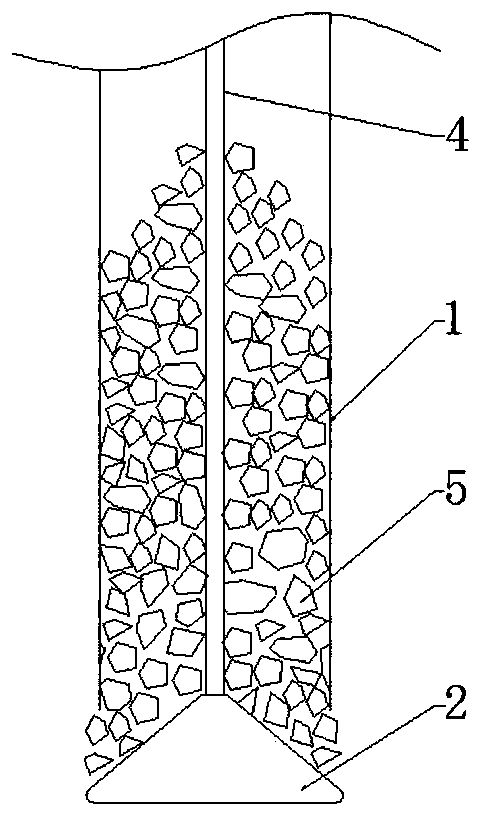

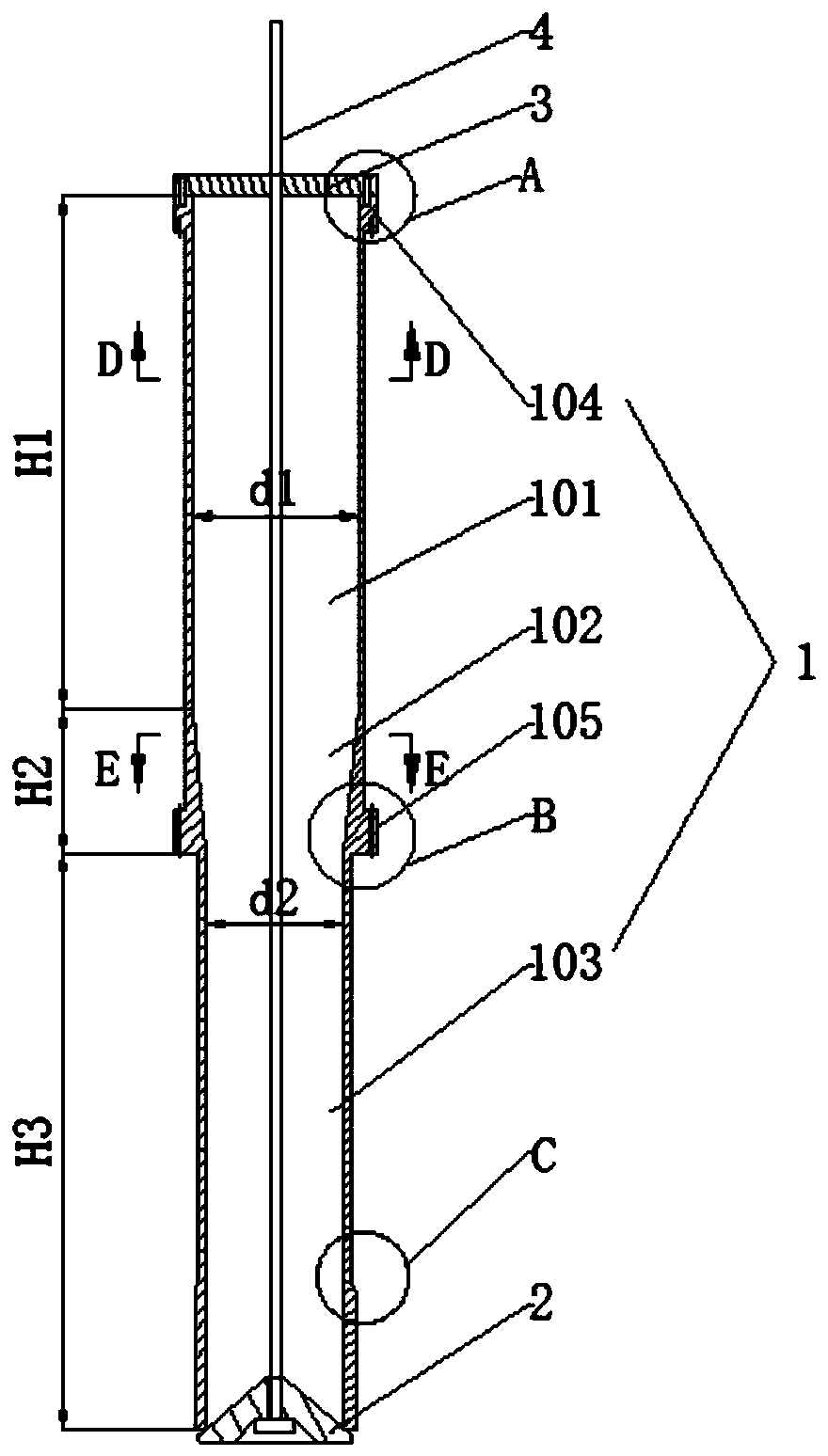

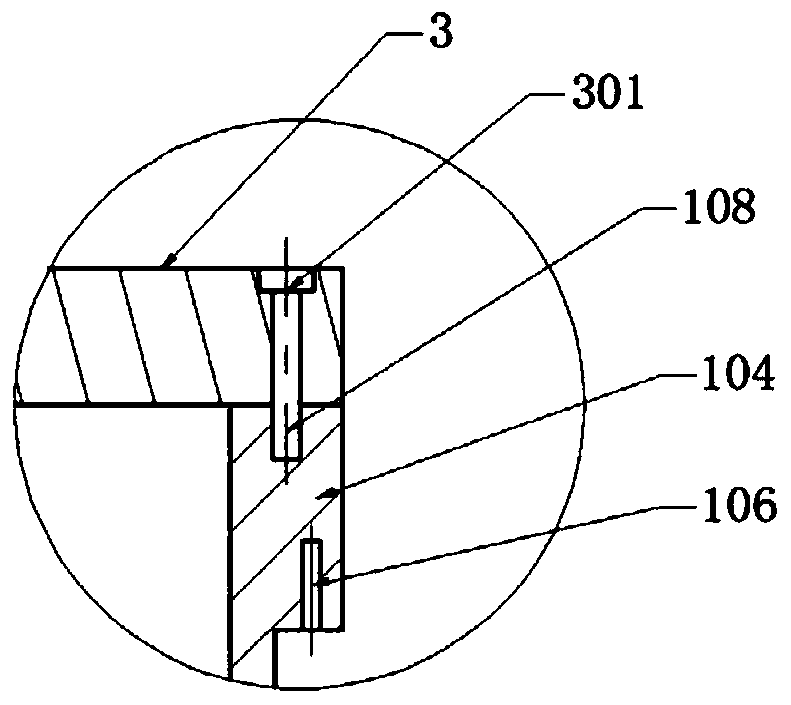

[0045] The present invention proposes a new re-investor for Czochralski single crystal, such as figure 2As shown, it includes the re-casting cylinder 1, the fixed frame 3 fixed on the upper port of the re-projected cylinder 1, the quartz umbrella 2 that blocks the lower port of the re-projected cylinder 1, and the quartz umbrella 2, the re-projected cylinder 1 and fixed on the fixed frame in turn. 3 on the tie rod 4. Wherein, the re-casting cylinder 1 comprises a first cylinder portion 101, a second cylinder portion 102 and a third cylinder portion 103 successively from an end close to the fixed frame 3, and the first cylinder portion 101, the second cylinder portion 102 and the third cylinder portion 103 is integrally formed, and the inner diameter d1 of the first cylindrical portion 101 is larger than the inner diameter d2 of the third cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com