Method for preparing nitrogen-doped nanoporous carbon microspheres by using sepia as raw material

A technology of nanopores and carbon microspheres, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of complex process, limited application of carbon materials, high cost, etc., and achieve good conductivity, The effect of high chemical stability and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

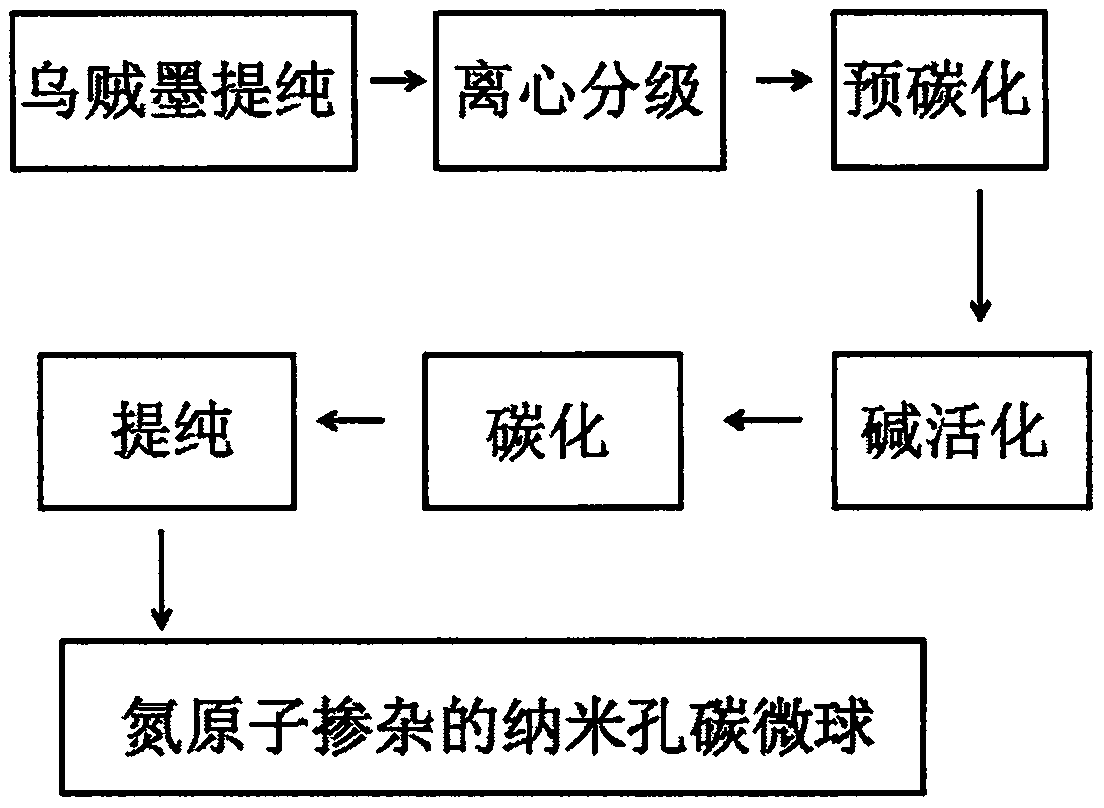

[0029] refer to figure 1 A method for preparing nitrogen-doped nanoporous carbon microspheres using squid ink as a raw material, comprising the following steps:

[0030] A. Take fresh squid, take out the ink sac, squeeze out the ink, and take the melanin of the sediment;

[0031] B, the deposit in step A is carried out pre-carbonization, then natural cooling;

[0032] C, the pre-carbonized product in step B is placed in potassium hydroxide aqueous solution and fully activated;

[0033] D, the activated product in step C is carbonized again, then naturally cooled;

[0034] E. Soak in hydrochloric acid solution;

[0035] F. Use pure water to filter, wash and dry to obtain monodisperse nanoporous carbon microspheres doped with nitrogen atoms.

[0036] In step A, soak in water at 0-25° C. for 8-12 hours, wash and separate several times at a speed of 500-12000 rpm, and collect the melanin of the precipitate.

[0037] In step B, the specific method of pre-carbonization is,

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com