Novel internal combustion truck energy supply system and method coupled with vehicle air conditioner

An energy supply system, a technology for internal combustion trucks, applied in vehicle components, air handling equipment, heating/cooling equipment, etc., can solve the problems of increasing system complexity, vehicle load, overall performance impact, and low utilization of AC equipment. The effect of improving fuel efficiency, reducing total weight and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

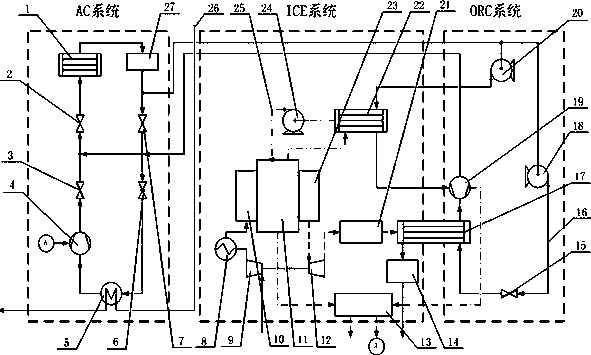

[0028] The ORC coupled diesel engine energy system diagram is shown in the attached figure, which consists of ICE, ORC and AC subsystems.

[0029] The specific thermal process of the ICE system is as follows: the air 26 is compressed by the air supercharger 9, the pressure and temperature rise slightly, and then enters the intercooler 8 for cooling, the static temperature drops, and the static pressure remains unchanged, and then enters the suction port 10 of the internal combustion engine for further processing. Compression, the pressure is greatly increased, and the internal combustion engine 11 is burned, and part of the heat released by the combustion is cooled by the coolant 25 and discharged into the atmosphere, most of which are used to increase the temperature of the gas. The exhaust turbine 12 continues to expand to atmospheric pressure, drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com