Simple laser intersecting line cutting machine

A laser cutting and intersecting line technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high price and lack of simple intersecting line cutting machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

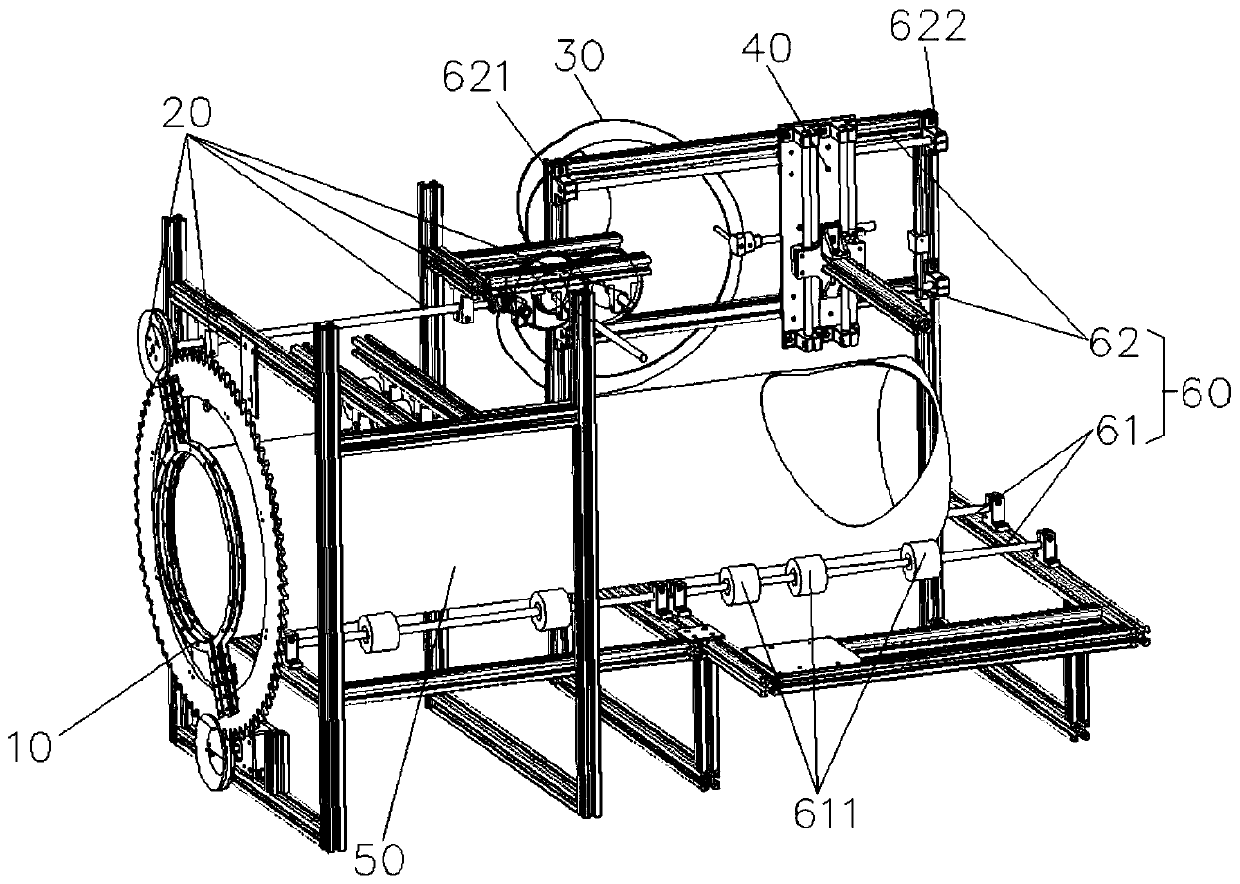

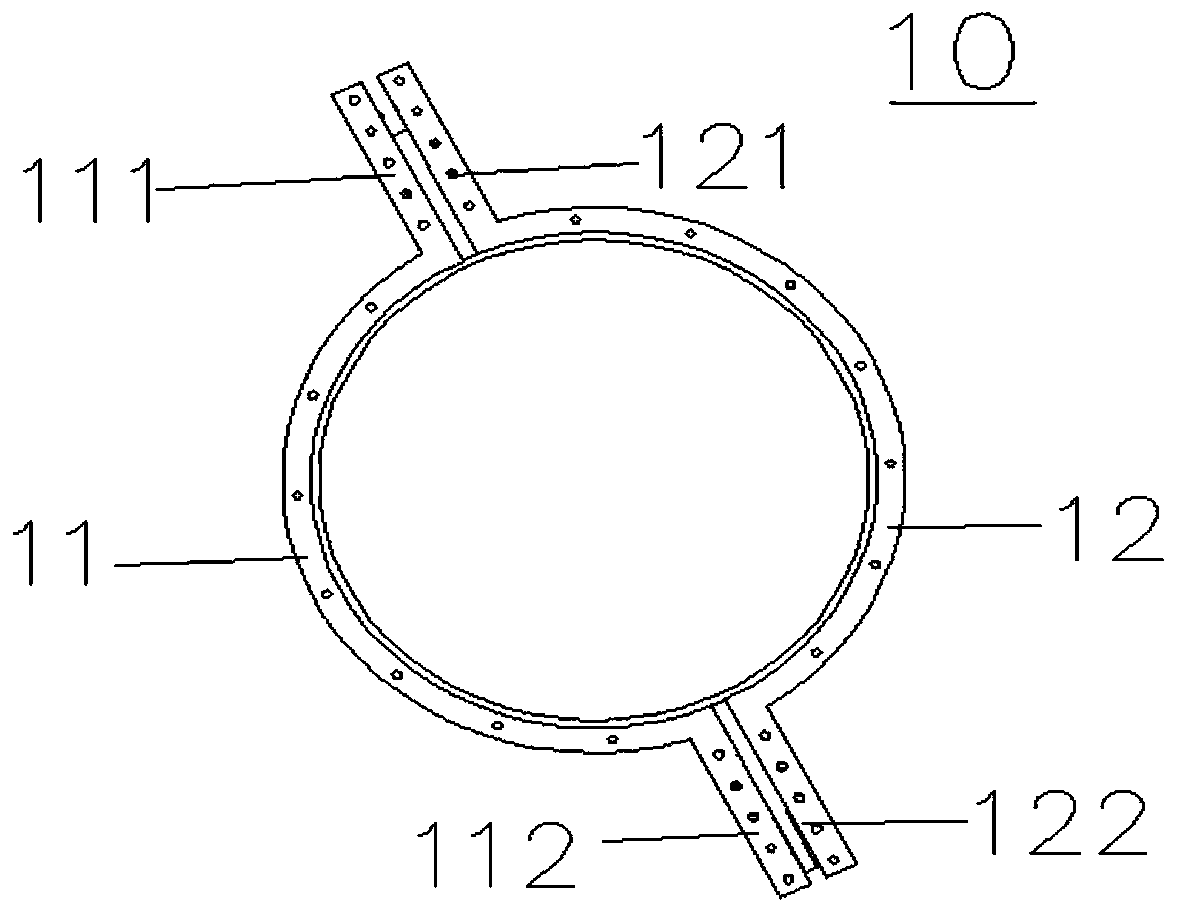

[0061] The invention provides a simple laser intersecting line cutting machine, such as figure 1 and Image 6 As shown, it includes: a pipe clamping fixture 10, a gear transmission assembly 20, a cam 30 and a laser cutting assembly 40;

[0062] The pipe clamping fixture 10 is used for clamping the pipe material 50 to be cut;

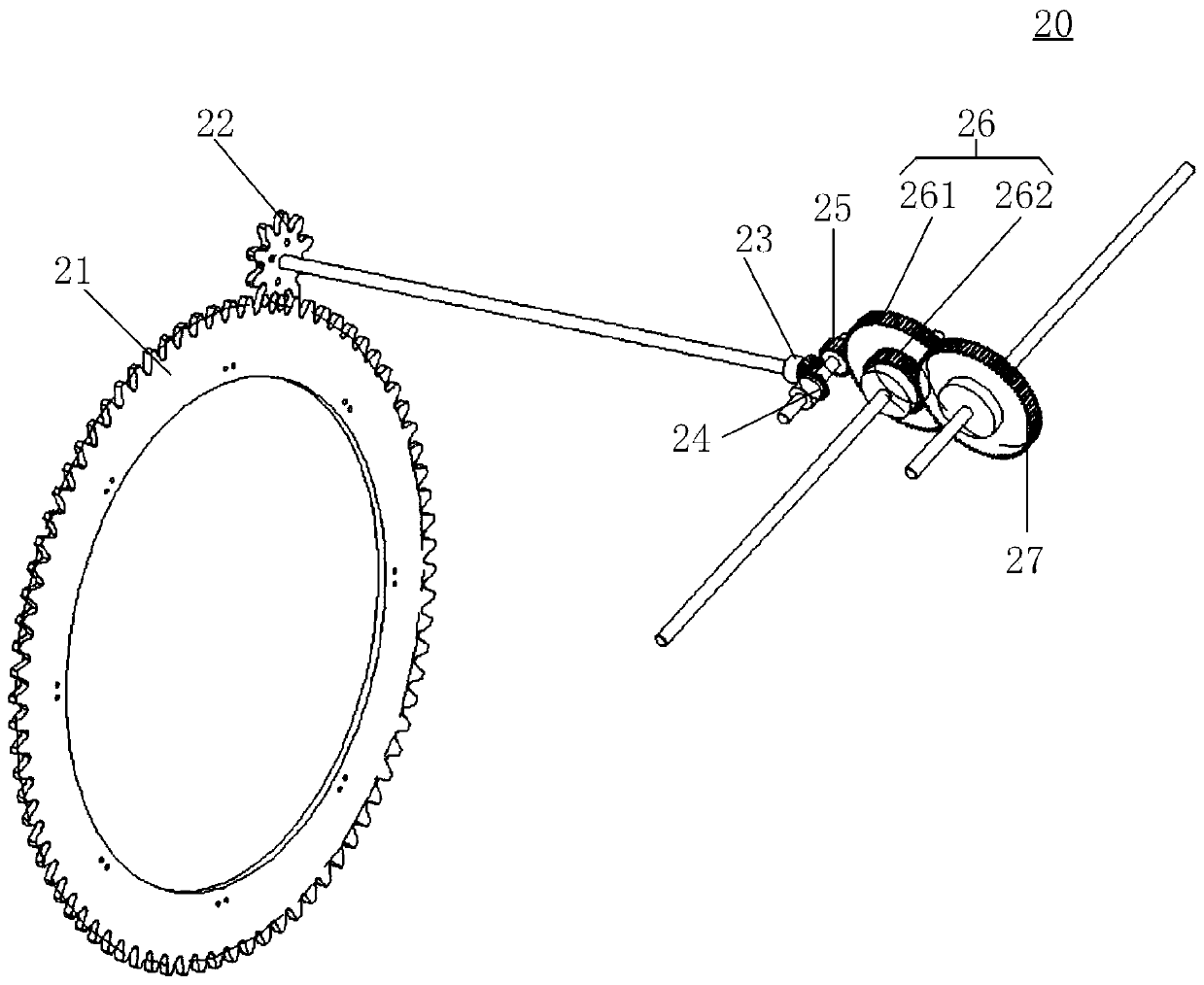

[0063] The gear transmission assembly 20 is connected with the pipe clamping fixture 10 , and the gear transmission assembly 20 rotates with the rotation of the pipe material 50 to be cut, wherein the gear transmission assembly 20 and the pipe clamping fixture 10 floating connection;

[0064] The gear transmission assembly 20 is connected to the cam 30, the gear transmission assembly 20 drives the cam 30 to rotate, and the cam 30 is used to generate the trajectory of the intersecting lines of the pipe material 50 to be cut;

[0065] The laser cutting assembly 40 includes a first sliding frame 41, a cam thimble 42 and a laser cutting head 43, and the c...

Embodiment 2

[0082] In a specific application scenario, in order to facilitate the cutting of intersecting lines on pipes, for example, when cutting intersecting lines on the same pipe, both radial intersecting lines and axial intersecting lines need to be cut on the same pipe. At this time, it is necessary to switch from the cam 30 for cutting radial intersecting lines to the cam 70 for cutting axial intersecting lines, and to replace the cam again, which is very troublesome and wastes man-hours. In order to switch from radial intersecting line cutting to axial intersecting line cutting conveniently and quickly, or convert axial intersecting line cutting to radial intersecting line cutting, the second embodiment of the present invention adopts the cam 30 Installed side by side with the cam 70, and installed on the simple laser intersecting line cutting machine at the same time, it can rotate with the gear transmission assembly 20 at the same time, so that the radial intersecting line and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com