Electric cooker capable of preventing rice soup from overflowing and control method thereof

A control method and technology of electric rice cooker, which is applied in the direction of preventing overflow, the structure of cooking utensils, cooking utensils, etc., can solve the problems of rice taste, such as the influence of boiling power and boiling time, and reduce the cooking effect of electric rice cooker, so as to achieve the effect of improving taste and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

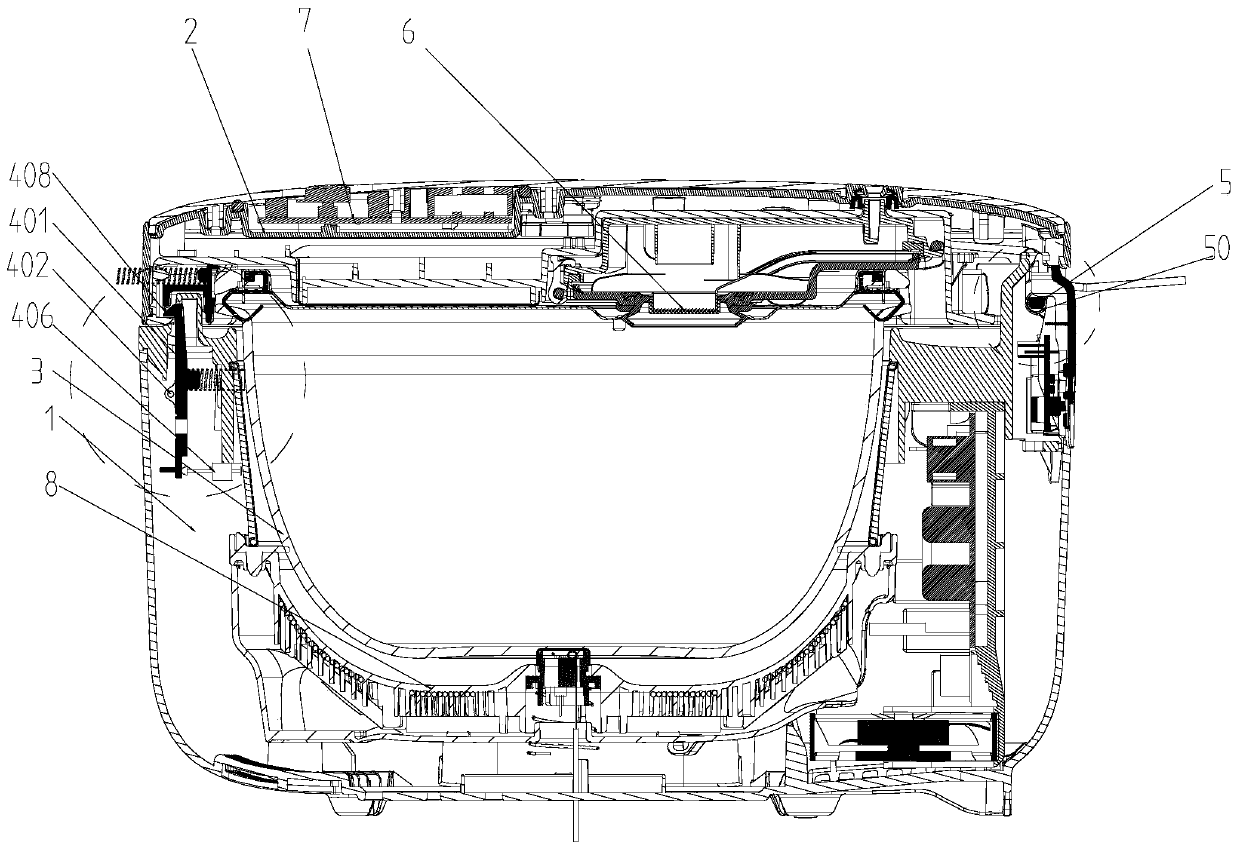

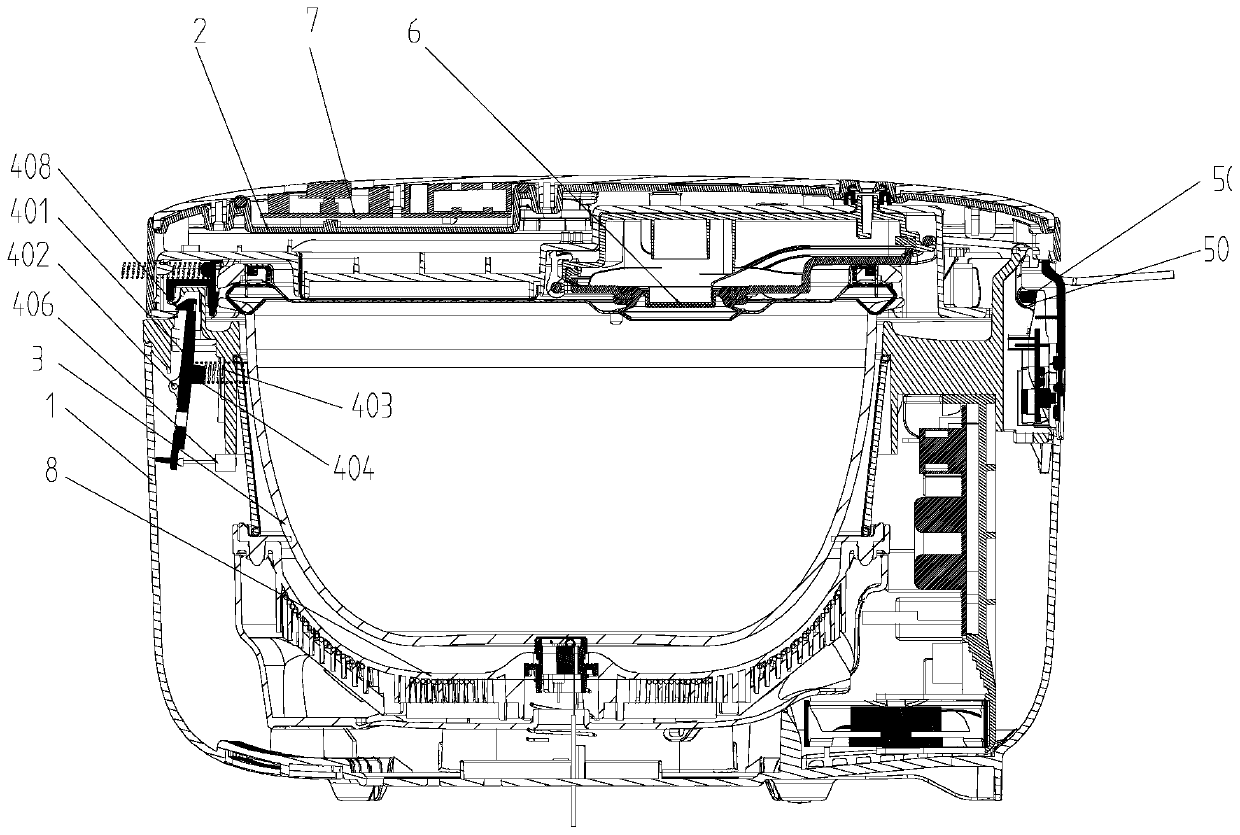

[0050] Embodiment one, such as Figure 1 to Figure 4 Shown:

[0051] The present invention is described in detail below in conjunction with the accompanying drawings. An electric rice cooker for preventing rice soup from overflowing includes a pot body 1 and a cover body 2. The pot body 1 is hingedly connected to the cover body 2, and the cover body 2 is buckled with the pot body 1 during cooking. The pot body 1 is equipped with an inner pot for containing ingredients, and the pot body 1 is provided with a micro-control component for controlling the work of the rice cooker. The micro-control component includes an MCU. , the lock assembly for unsealing the pot body and the lid body and the cover opening actuator assembly for rotating the lid relative to the pot body at a certain angle so as to leak steam. Pot or the heating device 8 that directly allows the inner pot to generate heat.

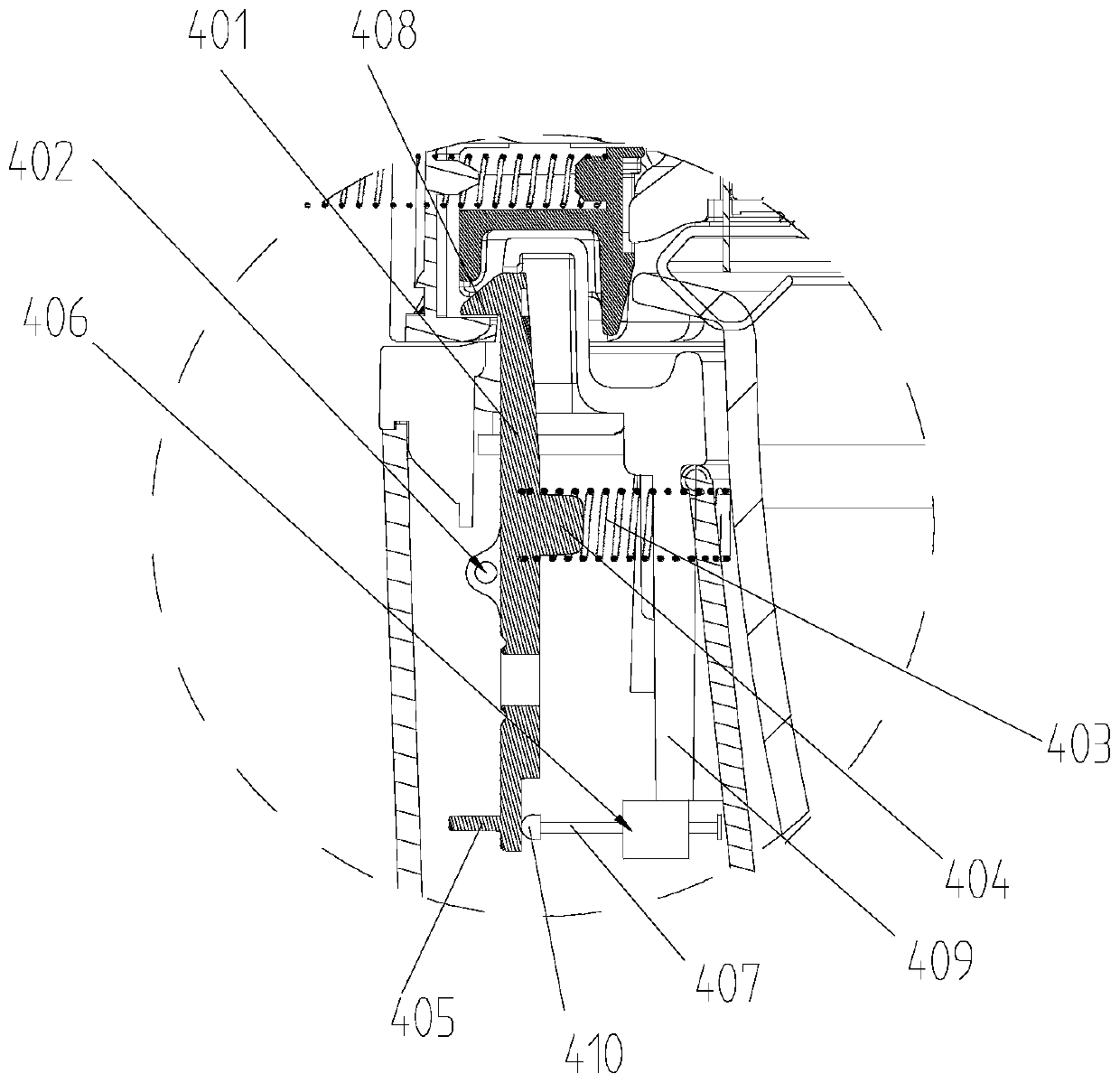

[0052]In this technical solution, further, the lock assembly includes a lever 401 and a so...

Embodiment 2

[0063] Embodiment two, such as Figure 5 Shown:

[0064] A control method applicable to an electric rice cooker for preventing rice soup from overflowing, the method comprises the following steps:

[0065] In step S01, the electric rice cooker is powered on and starts cooking;

[0066] In step S02, use the rice soup foam detection component to detect whether the height of the rice soup foam reaches the limit position, if it reaches the limit position, then exit step S02 and enter step S03, otherwise continue to execute step S02;

[0067] In step S03, the solenoid valve assembly is started, the solenoid valve slide bar extends forward, the lever 401 is pushed to rotate around the lever bearing 402, the tab 408 is disengaged from the slot formed on the lower surface of the cover body 2, the lock assembly is released, and the cover body and the pot body unsealed;

[0068] In step S04, the MCU controller counts t1;

[0069] In step S05, judge whether Δt1 is greater than 10ms, ...

Embodiment 3

[0076] Embodiment three, such as Figure 6 Shown:

[0077] A method for controlling an electric rice cooker for preventing rice soup from overflowing, the method comprises the following steps:

[0078] In step S01, the electric rice cooker is powered on and starts cooking;

[0079] In step S02, time t0;

[0080] In step S03, judge whether t0≤25min, when Δt0 satisfies the condition, exit step S03, enter step S04; otherwise exit step S03, enter step S013;

[0081] In step S04, detect whether the foam height of rice soup reaches the limit position by the rice soup foam detection component, if it reaches the limit position, then exit step S04 and enter step S05, otherwise continue to execute step S04;

[0082] In step S05, the solenoid valve assembly is activated, the solenoid valve slide bar extends forward, the lever 401 is pushed to rotate around the lever bearing 402, the tab 408 is disengaged from the slot formed on the lower surface of the cover body 2, the lock assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com