Lithium-ion power battery life testing device

A power battery and life testing technology, applied in secondary battery testing, secondary battery, secondary battery repair/maintenance, etc. shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

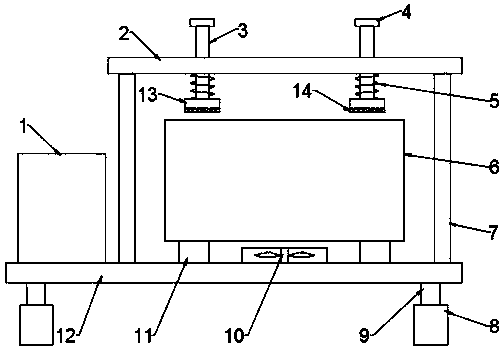

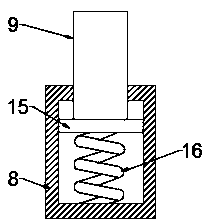

[0022] see Figure 1-2 , in an embodiment of the present invention, a lithium-ion power battery life testing device includes a battery life testing device 1 and a base plate 12, the battery life testing device 1 is installed on the base plate 12, and a support block 11 is installed on the upper end surface of the base plate 12, preferably Yes, the number of support blocks 11 is four, and the four support blocks 11 are distributed in a rectangular shape. The setting of the four support blocks 11 is convenient for placing the lithium-ion power battery body 6, and plays the role of carrying the lithium-ion power battery body 6; The lower side of the base plate 12 is provided with a shock-absorbing seat 8 and a shock-absorbing inner rod 9, the shock-absorbing inner rod 9 is connected to the lower end surface of the base plate 12, the shock-absorbing seat 8 is an internal hollow structure, and the shock-absorbing inner rod 9 runs through the shock-absorbing seat 8 and is slidably c...

Embodiment 2

[0026] see Figure 1-2 , in the embodiment of the present invention, a lithium-ion power battery life testing device is different from embodiment 1 in that a top plate 2 is provided on the upper side of the bottom plate 12, and a support column 7 is connected between the top plate 2 and the bottom plate 12, Preferably, the number of support columns 7 is four, and the tops of the four support columns 7 are respectively connected to the lower end surface of the top plate 2 near the four corners. The top plate 2 is provided with a battery pressing mechanism, which can Compress the lithium-ion power battery body 6 to avoid movement or shaking of the lithium-ion power battery body 6 during the test.

[0027] Specifically, the battery pressing mechanism includes a sliding bar 3 and a pressing plate 13, the sliding bar 3 runs through the top plate 2 and is slidably connected with it, so that the sliding bar 3 can slide up and down, and the pressing plate 13 is arranged at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com