Intelligent high-speed train white body assembly quality detection device and method

A detection device and body-in-white technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inability to adapt to multi-shape, multi-angle measurement, failure to achieve accurate size measurement of the area of interest, and high system cost, so as to achieve improvement Test quality and efficiency, speed up manufacturing and precision, high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

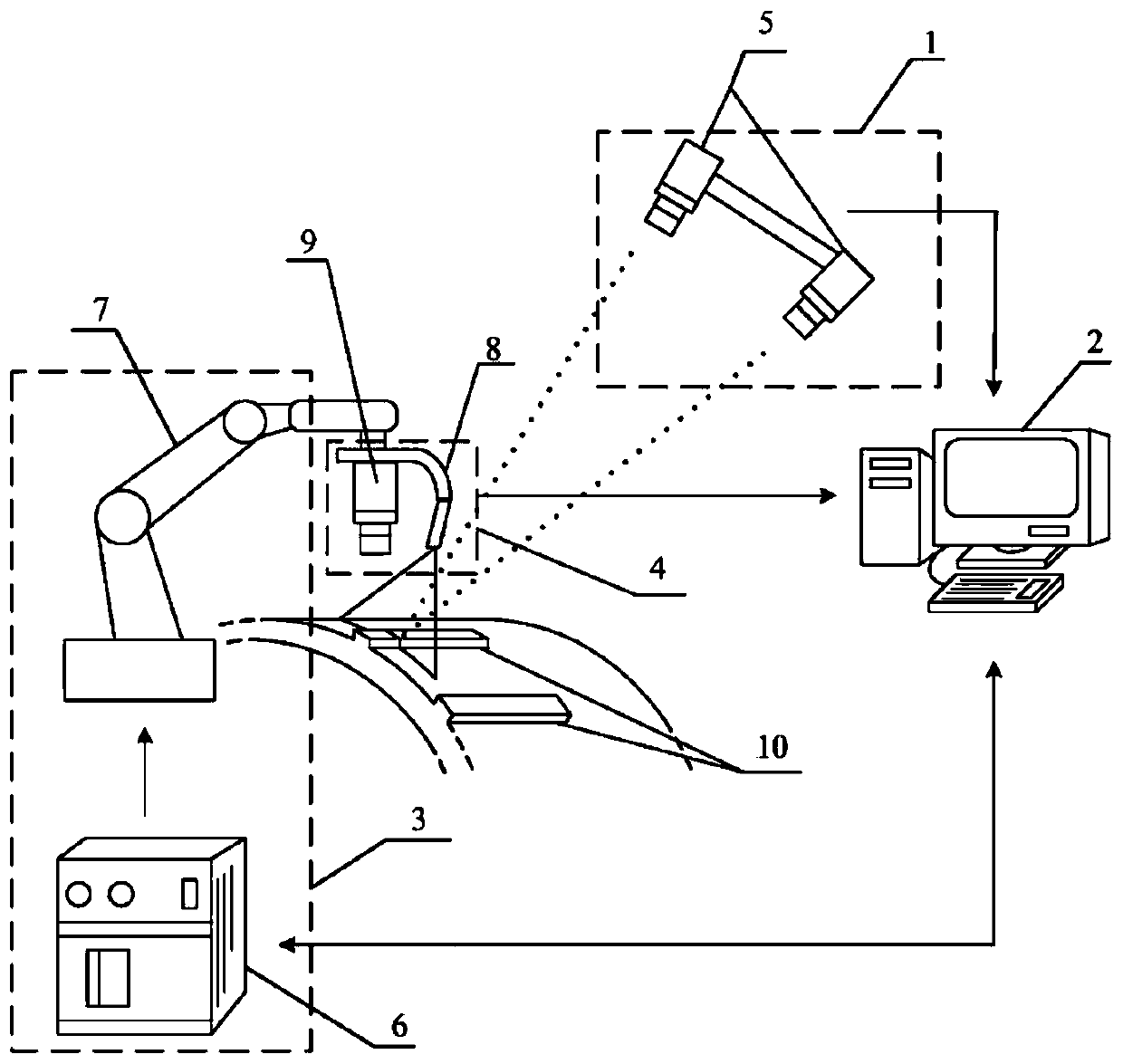

[0026] figure 1 Among them, 1 is the stereo vision sensor, 2 is the computer, 3 is the manipulator system, 4 is the structured light vision sensor device, 5 is the binocular camera, 6 is the manipulator controller, 7 is the industrial manipulator, 8 is the laser emission device, 9 is a CCD camera, and 10 is a positioning mark.

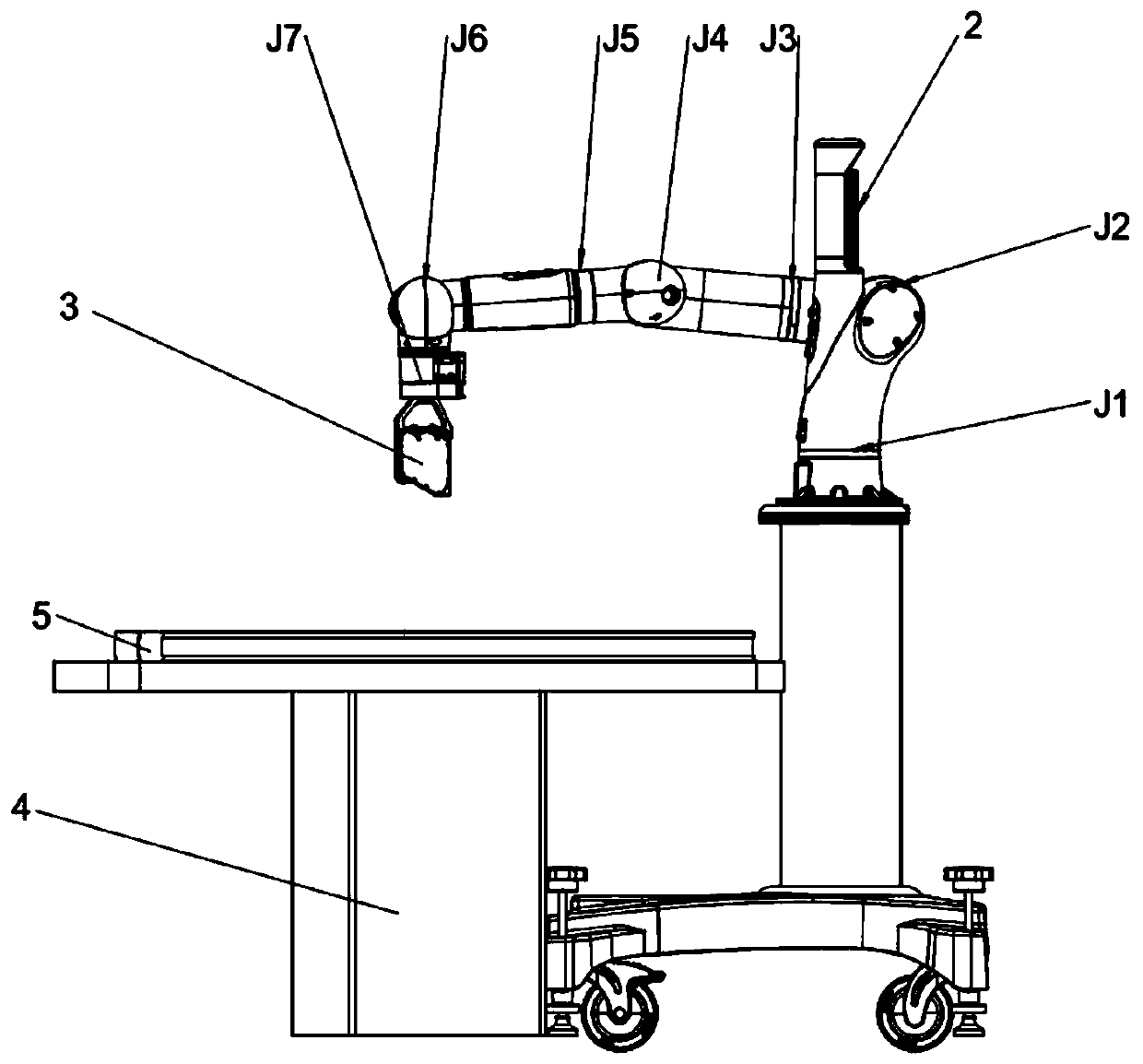

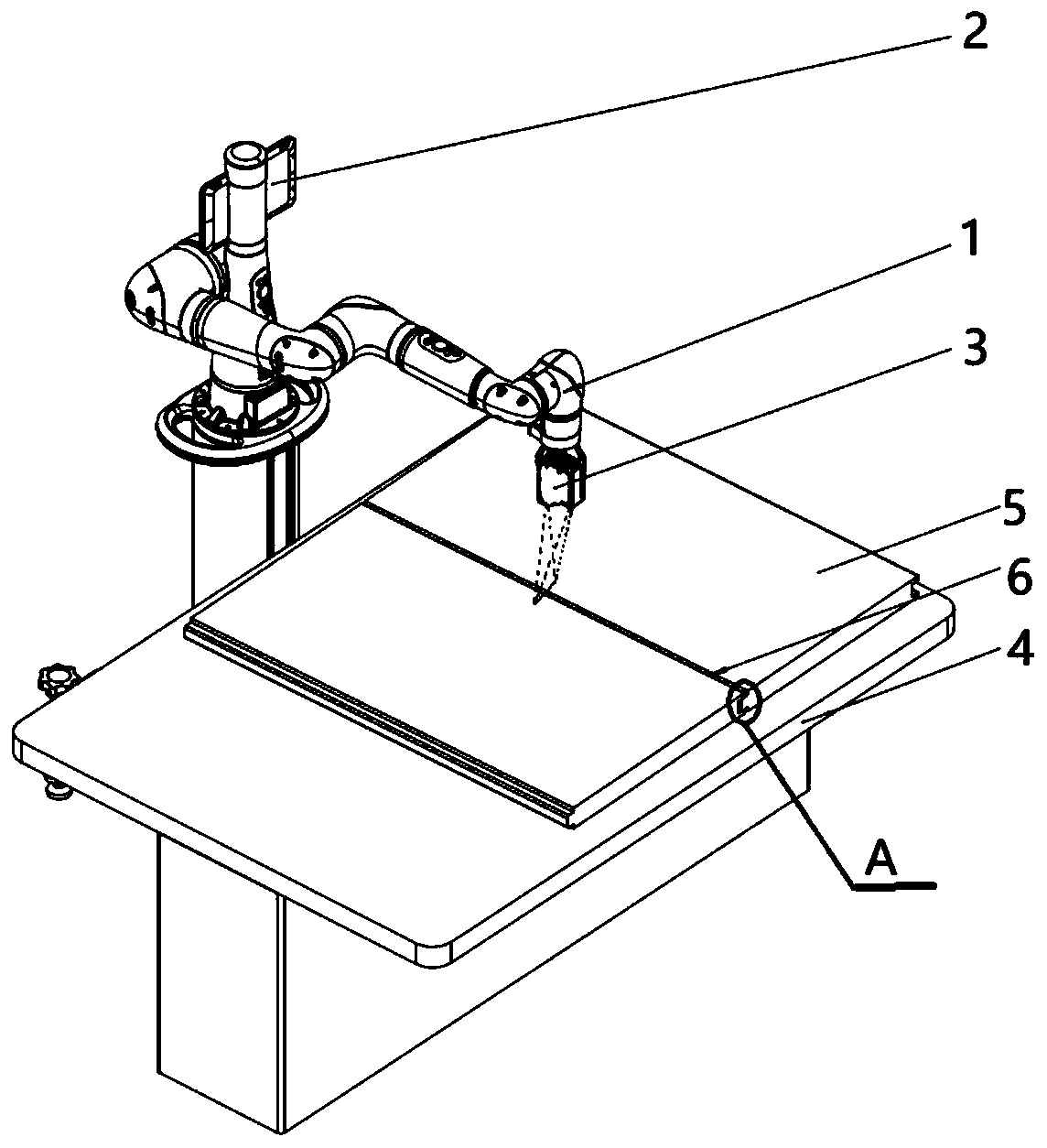

[0027] figure 2 , image 3 It shows an intelligent high-speed rail body-in-white assembly quality inspection device, which includes a computer-controlled mechanical arm, and the seven-axis mechanical arm 1 is equipped with a display connected to the computer. Screen 2, two-dimensional laser sensor 3 is installed at the end of this seven-axis mechanical arm 1, and two-dimensional laser sensor 3 is connected with described computer, and above-mentioned seven-axis mechanical arm 1 is installed on the movable trolley ( figure 2 , image 3 As shown, the assembly feature 6 to be tested, the body-in-white profile 5, and the tooling frame 4). The displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com