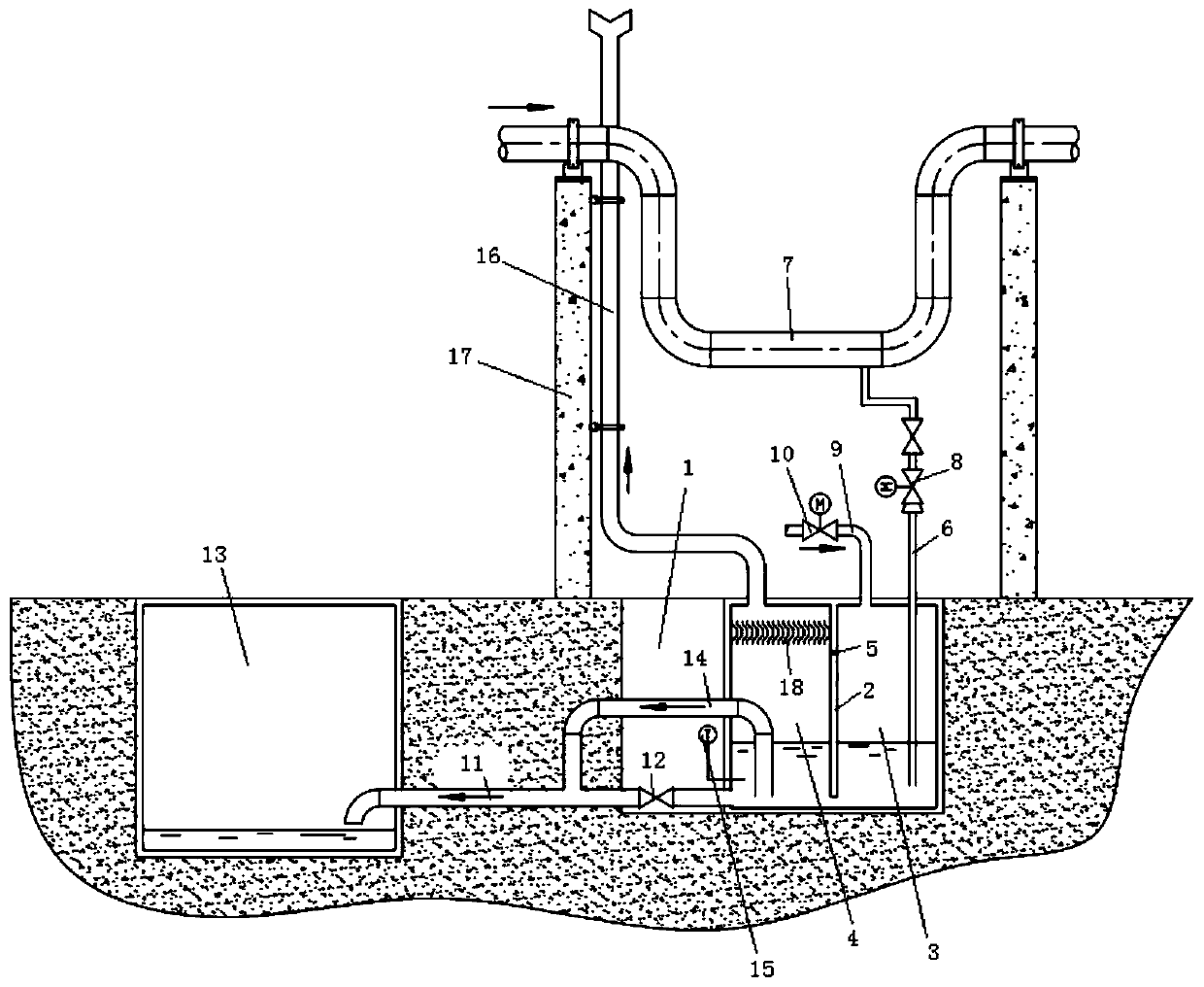

Environmental-friendly steam pipeline drainage collection system and working method

A technology of steam pipeline and collection system, applied in the field of environment-friendly steam pipeline drainage collection system, can solve the problems of plastic material damage and failure, accumulation of water, freezing, etc., and achieve the effect of ensuring hygiene and beauty, wide application range and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0035] This embodiment discloses a working method of a steam pipeline drainage collection system:

[0036] Open the third valve, inject a set amount of cooling water into the chamber in advance through the cooling pipe, the cooling water level is higher than the bottom of the drain pipe, and slightly lower than the height of the highest point of the overflow pipe, and then close the third valve. When the steam pipeline in the factory area needs to be drained, open the second valve, and the drain pipe will lead the high-temperature drain into the mixed temperature chamber to mix with the cooling water in the mixed temperature chamber to cool it down. The mixed water with lower temperature flows into the discharge chamber through the gap between the partition and the bottom surface of the chamber, mixes with the cooling water in the discharge chamber again, and cools down again. When the liquid level of the mixed water in the discharge chamber exceeds the overflow pipe At the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com