Assembly type external corner installing structure and method of skirting line

A technology for installing structure and skirting line, which is applied in the direction of building structure and construction, and can solve the problems of inability to assemble the joints, complicated installation steps of the skirting line, and deterioration of the appearance and quality of the outer corner of the skirting line.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

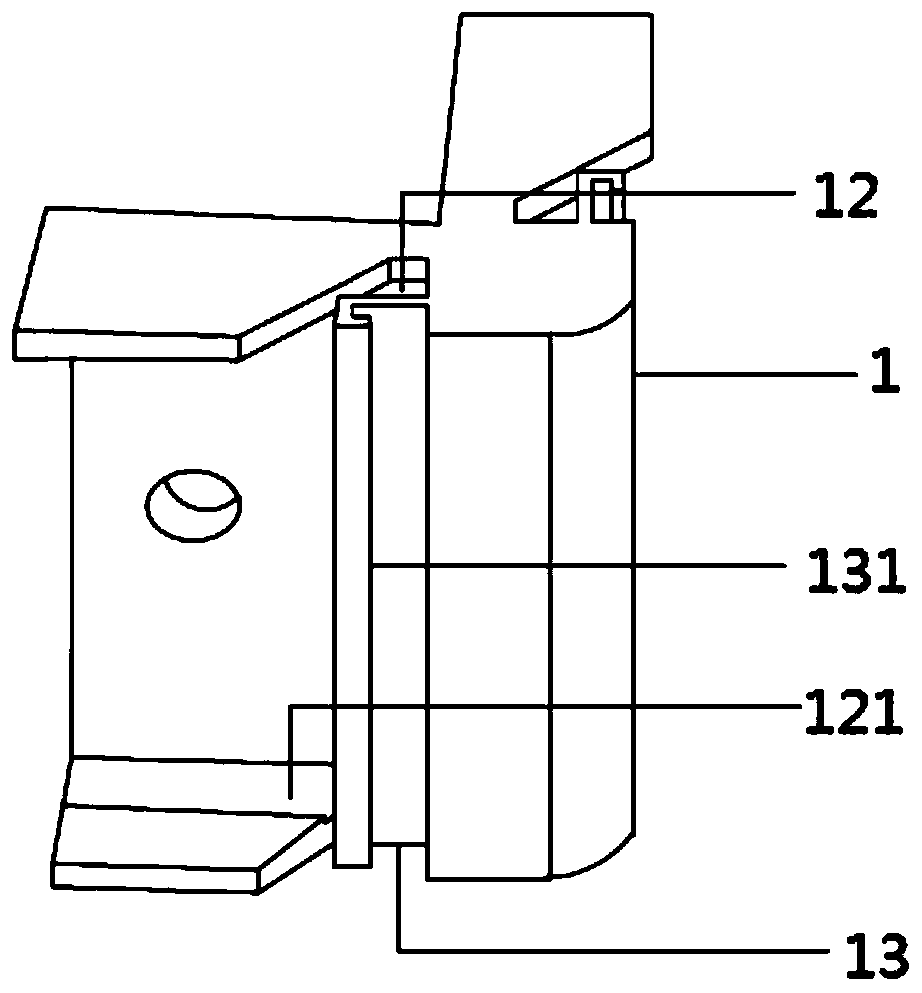

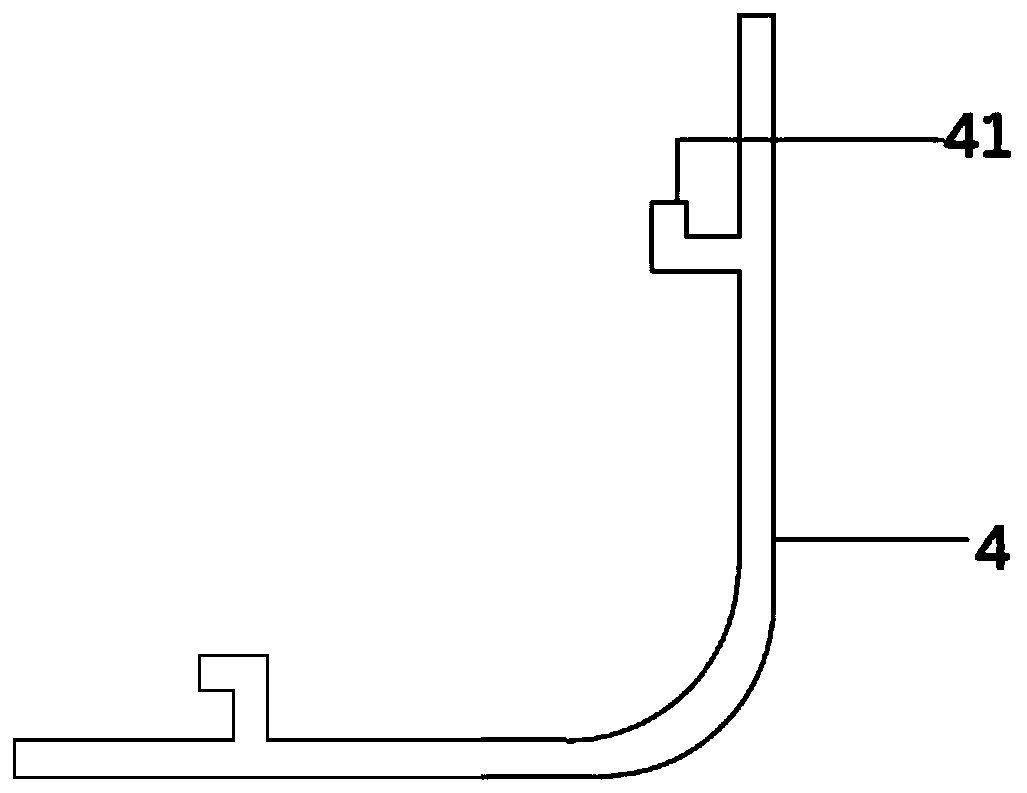

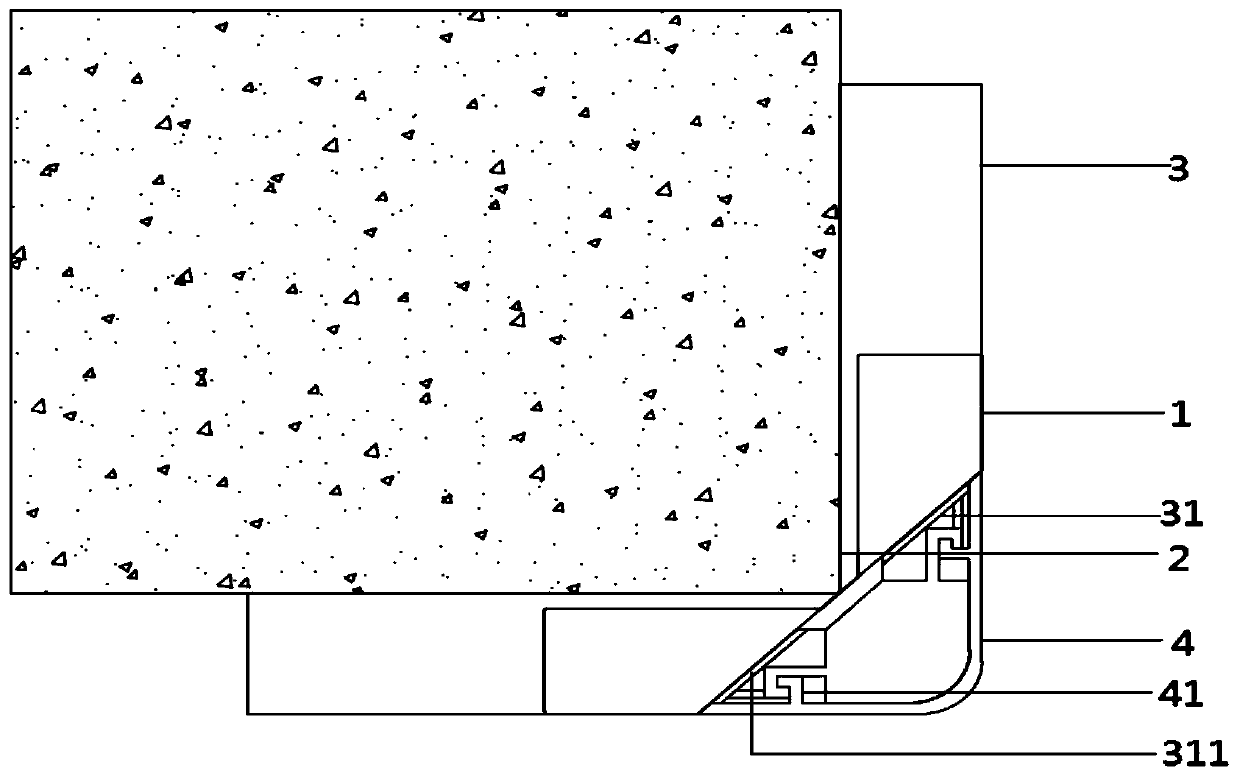

[0029] see Figure 1 to Figure 4 , the figure shows a prefabricated male corner installation structure of skirting line provided by Embodiment 1 of the present invention, which mainly includes male corner clip 1 and male corner blocking plate 4, wherein male corner clip 1 is a The L-shaped plate body, the male corner clip 1 is fixedly connected to the male corner 2 of the wall, and the opposite side plates of the male corner clip 1 are respectively provided with two first card slots 12, the cross section of the first card slot 12 It is triangular, and the end face of the skirting line 3 is provided with a clamping part 31. The clamping part 31 can be a clamping plate specifically, and the clamping plate is clamped in the first clamping groove 12, and the male corner blocking plate 4 is also an L-shaped plate body, and the inner surface of the male corner blocking plate 4 is provided with a hook body 41, the hook body 41 is specifically an L-shaped hook, and the L-shaped hook i...

Embodiment 2

[0038] see Figure 1 to Figure 4 , the figure shows a prefabricated external corner installation structure and installation method of skirting provided by Embodiment 2 of the present invention. This embodiment further makes the following improvements on the basis of the above-mentioned embodiments Technical solution: the included angle of the first locking groove 12 is 45 degrees, and the angle between the locking part 31 and the main body of the baseboard 3 is 45 degrees.

[0039] Through the setting of the above structure, when clamping the male corner clip and the skirting line, inserting the clip into the first slot can ensure the perfect connection between the groove of the male corner clip and the clipping part, and can provide a perfect connection between the two surfaces. It provides stable support, simplifies the installation process, and can realize rapid installation, thereby improving work efficiency and saving labor costs.

Embodiment 3

[0041] see Figure 1 to Figure 4 , the figure shows a prefabricated external corner installation structure and installation method of skirting provided by Embodiment 3 of the present invention. This embodiment further makes the following improvements on the basis of the above-mentioned embodiments Technical solution: After the clamping part 31 is clamped into the second clamping slot 13, a cavity 311 with a rectangular cross section is formed between the clamping part 31 and a groove wall of the first clamping slot 12, and the materials used for decoration will expand and cool with heat There is a cavity between the clamping part and the male corner clamping part, which can avoid the deformation of the overall structure caused by the expansion of the material, so as not to affect the appearance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com