Deepwater pipe culvert anti-floating control system

A technology for control systems and deep water pipes, which is applied to the bottom layer of roads, protection devices, buildings, etc., can solve problems such as uneven stress on pipes and culverts, high construction costs, uneven settlement, etc., and achieve fast construction, enhanced overall strength, and structural integrity. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

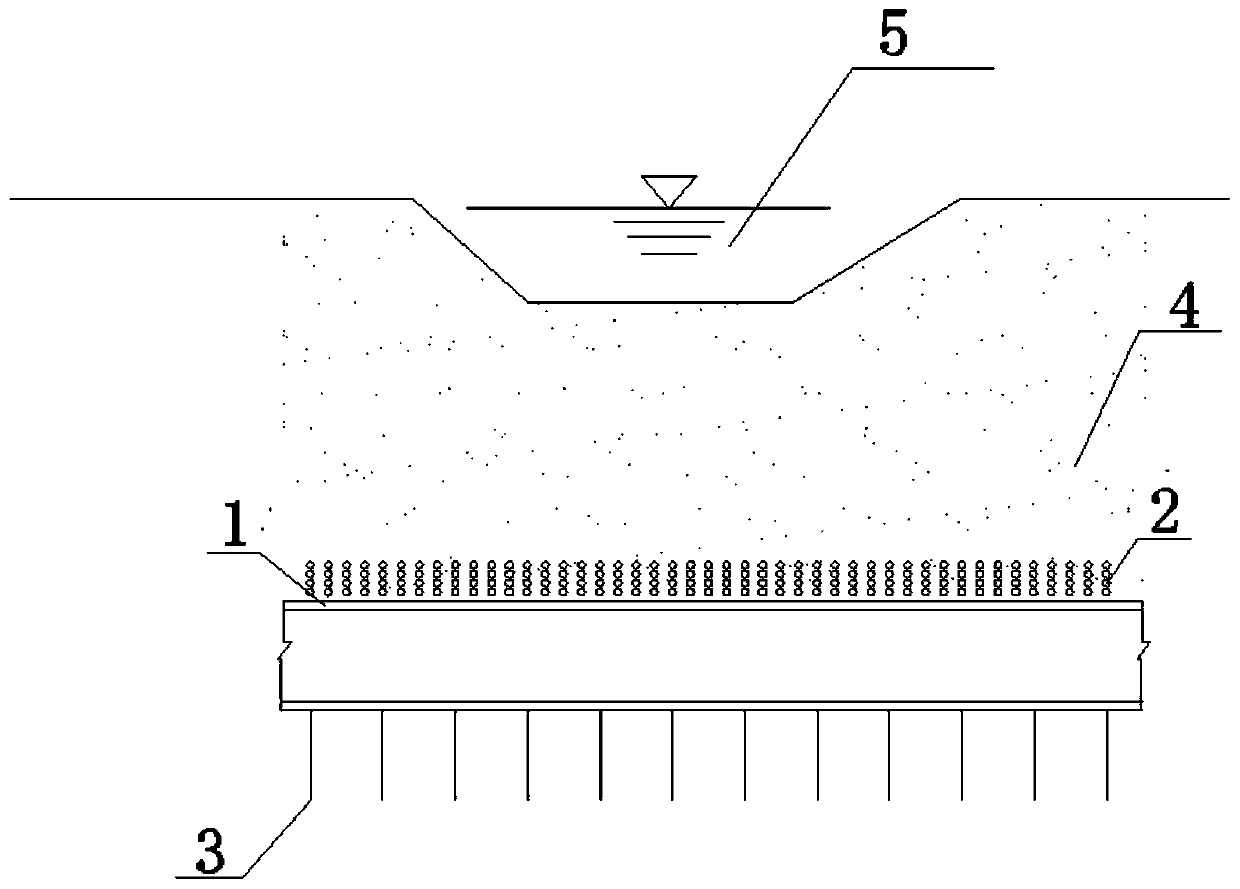

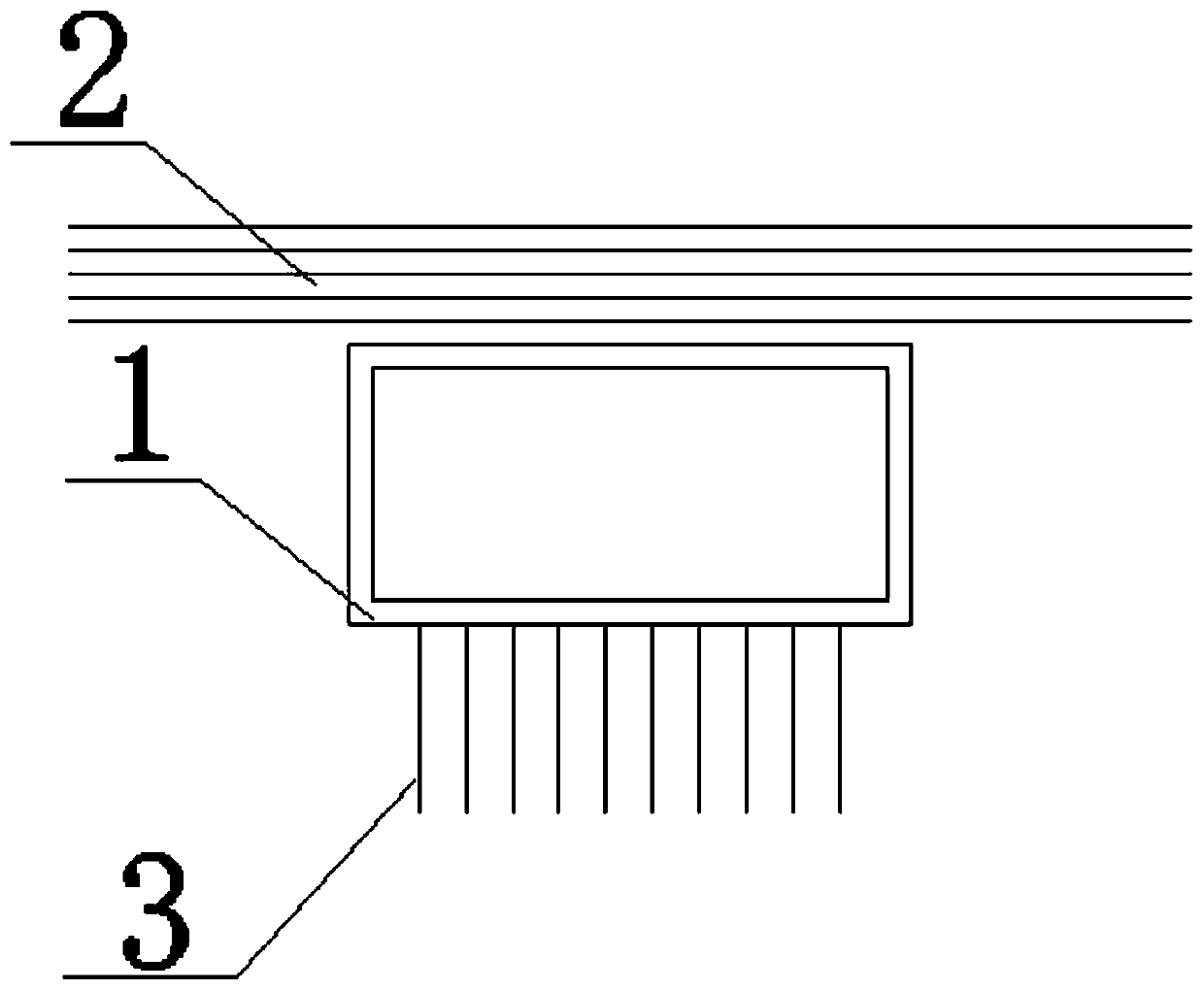

[0019] The deep-water pipe culvert anti-floating system provided in this embodiment is mainly applied to pipe culverts located in large water depths and large water level variations. This embodiment discloses an anti-floating control system for deep water pipe culverts, including pipe culverts 1 , tendons 2 and anchor rods 3 .

[0020] see figure 1 and figure 2 , the pipe culvert 1 passes through the river 5. The pipe culvert 1 is embedded in a sandstone grouting foundation or a rock formation foundation. The pipe culvert 1 is covered with a soil filling layer 4 . Several ribs 2 are arranged in the soil filling layer 4 . The length direction of the ribs 2 is perpendicular to the length direction of the pipe culvert 1 . Several anchor rods 3 are arranged under the pipe culvert 1 . The upper end of the anchor rod 3 is connected to the pipe culvert 1, and the lower end is anchored into the sandstone grouting foundation or rock formation foundation. The pipe culvert 1 gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com