Soft soil foundation curing agent prepared from industrial waste residues

A technology of industrial waste and soft soil foundation, which is applied in the field of soft soil foundation treatment, to reduce engineering costs, solve the shortage of cement, and improve the unconfined compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

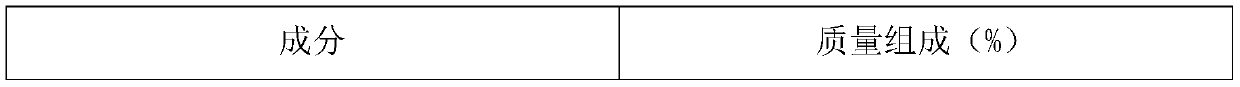

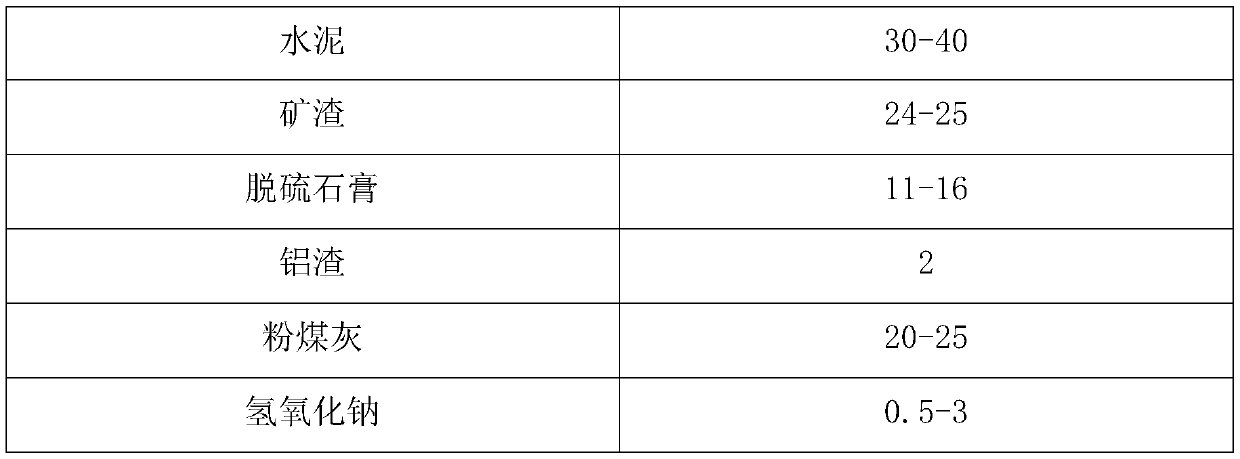

[0032] Firstly prepare a muddy curing agent, its components include cement 30%, slag 25%, desulfurization gypsum 14.5%, aluminum slag 2%, fly ash 28%, sodium hydroxide 0.5%, named RTGHJ1.

[0033] Add 9% curing agent to the three soil samples with water content w of 65%, 75% and 85% respectively, mix and stir evenly to obtain the solidified soil specimen. Put the sample into a plastic fresh-keeping bag after being sprinkled with water and wet it. As for the standard curing indoor curing, the curing temperature is controlled at about 25 degrees, the relative humidity is greater than or equal to 95%, and the curing is measured for 7 days until the required age. , Unconfined compressive strength at 28d age, as shown in Table 3.

[0034] Table 3. Unconfined compressive strength of RTGHJ1 under different water contents

[0035] age W=65% W=75% W=85% 7d 336kpa 303kpa 285kpa 28d 382kpa 358kpa 324kpa

Embodiment 2

[0037] First prepare the muddy curing agent, its components include cement 35%, slag 25%, desulfurization gypsum 14.5%, aluminum slag 2%, fly ash 23%, sodium hydroxide 0.5%, named RTGHJ2.

[0038] Add 9% curing agent to the three soil samples with water content w of 65%, 75% and 85% respectively, mix and stir evenly to obtain the solidified soil specimen. Put the sample into a plastic fresh-keeping bag after being sprinkled with water and wet it. As for the standard curing indoor curing, the curing temperature is controlled at about 25 degrees, the relative humidity is greater than or equal to 95%, and the curing is measured for 7 days until the required age. , Unconfined compressive strength at 28d age, as shown in Table 4.

[0039] Table 4. Unconfined compressive strength of RTGHJ2 at different water contents

[0040] age W=65% W=75% W=85% 7d 340kpa 313kpa 289kpa 28d 381kpa 376kpa 331kpa

Embodiment 3

[0042] Firstly prepare a muddy curing agent, its components include 40% cement, 24% slag, 11% desulfurized gypsum, 2% aluminum slag, 20% fly ash, 3% sodium hydroxide, named RTGHJ3.

[0043] Add 9% curing agent to the three soil samples with water content w of 65%, 75% and 85% respectively, mix and stir evenly to obtain the solidified soil specimen. Put the sample into a plastic fresh-keeping bag after being sprinkled with water and wet it. As for the standard curing indoor curing, the curing temperature is controlled at about 25 degrees, the relative humidity is greater than or equal to 95%, and the curing is measured for 7 days until the required age. , Unconfined compressive strength at 28d age, as shown in Table 5.

[0044] Table 5. Unconfined compressive strength of RTGHJ3 under different water contents

[0045] age W=65% W=75% W=85% 7d 558kpa 532kpa 503kpa 28d 605kpa 598kpa 551kpa

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com