Lithium battery cap assembling machine for achieving feeding by adopting bidirectional negative pressure principle

A lithium battery and assembly machine technology, which is applied in the manufacture of lithium batteries, non-aqueous electrolyte batteries, and electrolyte batteries, etc. It can solve the problems of irregular arrangement of lithium batteries, low accuracy, and slow export progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

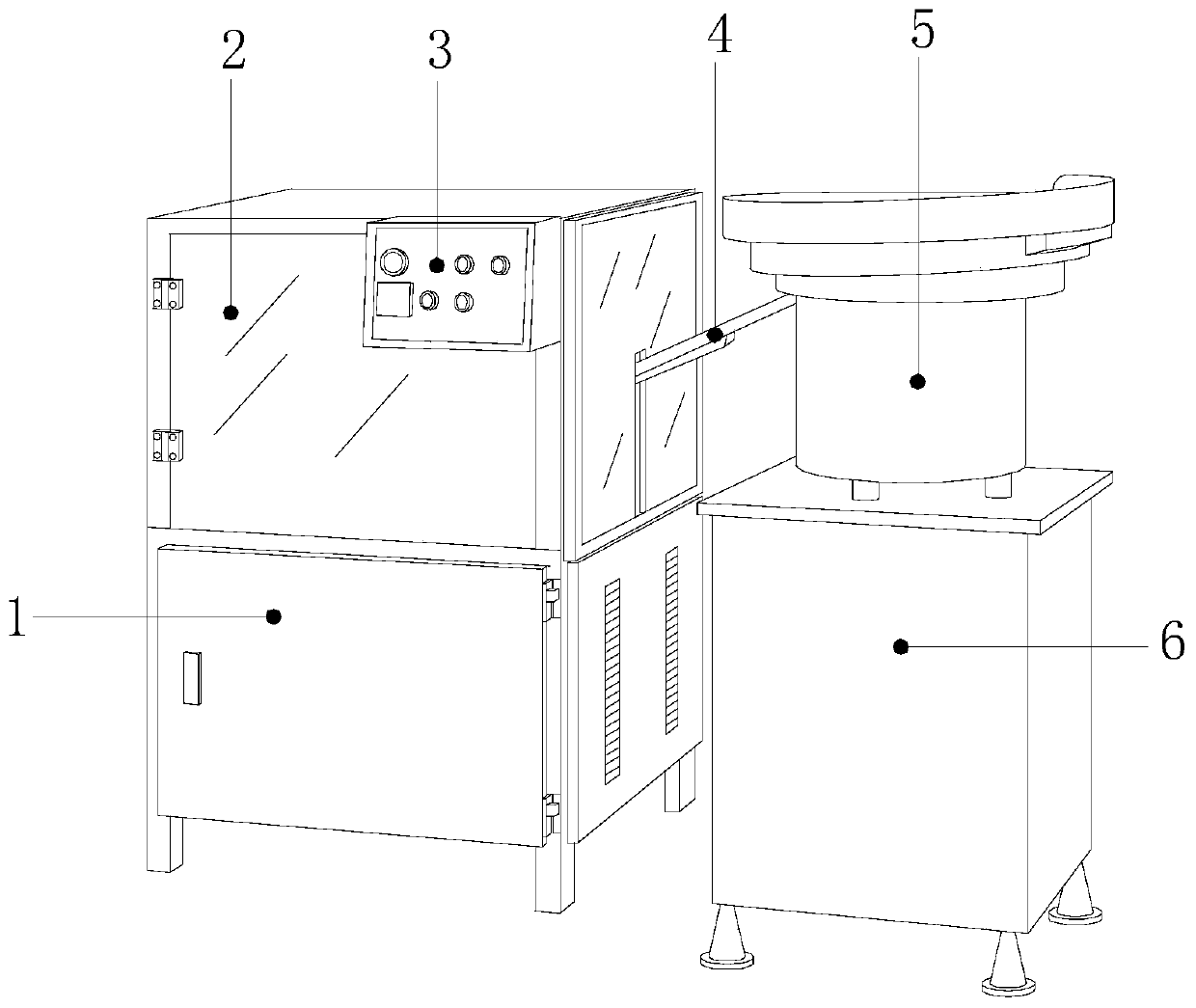

[0029] see Figure 1-Figure 6 , the present invention provides a lithium battery cap assembly machine that adopts the two-way negative pressure principle to feed materials. The bottom of the feeding device 5 is installed on the top of the electric control cabinet 6 by buckling, the electric control cabinet 6 is located on the right side of the assembly host 1, and the top of the assembly host 1 is provided with a processing chamber 2, which is an integrated structure. The controller 3 is installed on the upper right end of the processing chamber 2 by buckling, the feeding device 5 is connected with the processing chamber 2 through the connecting bridge 4, the lithium battery cap is put into the feeding device 5, and the electric control cabinet 6 is started Carry out operation, and through connecting bridge 4, block cap is evenly introduced in processing chamber 2 and assembled.

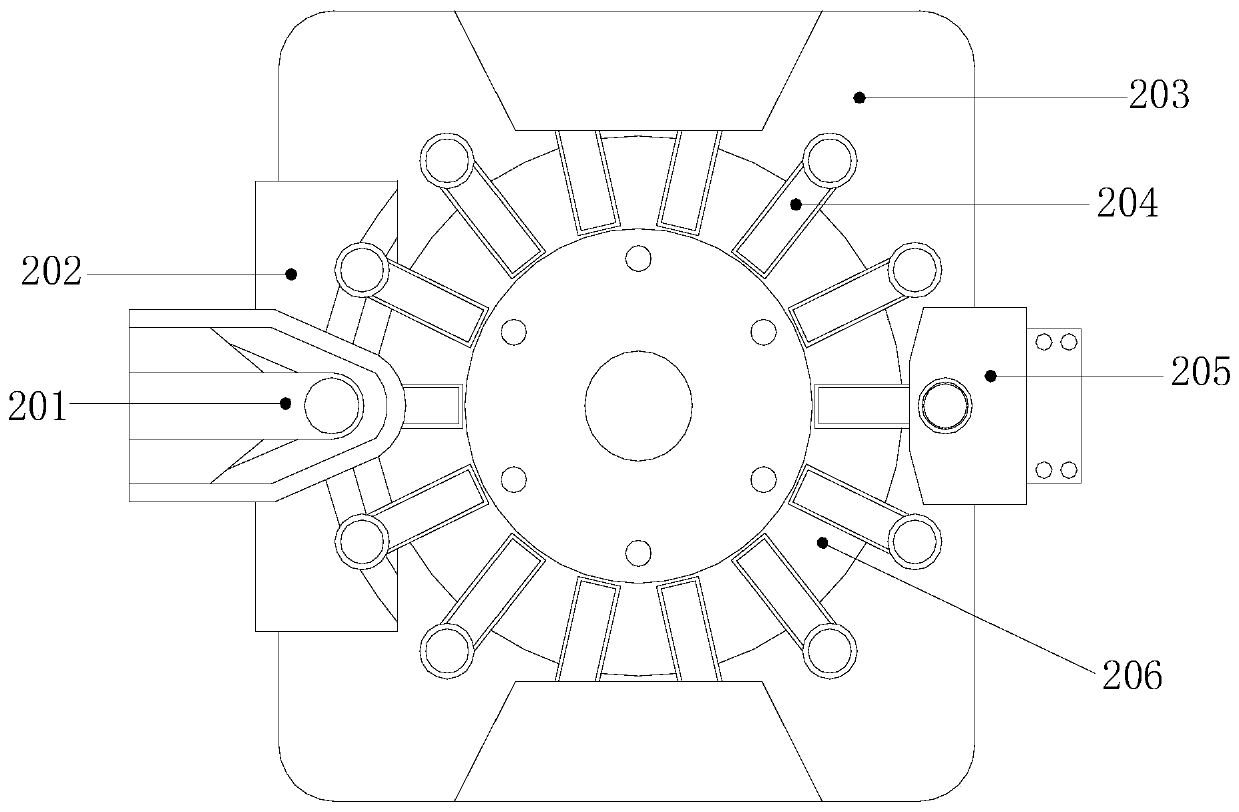

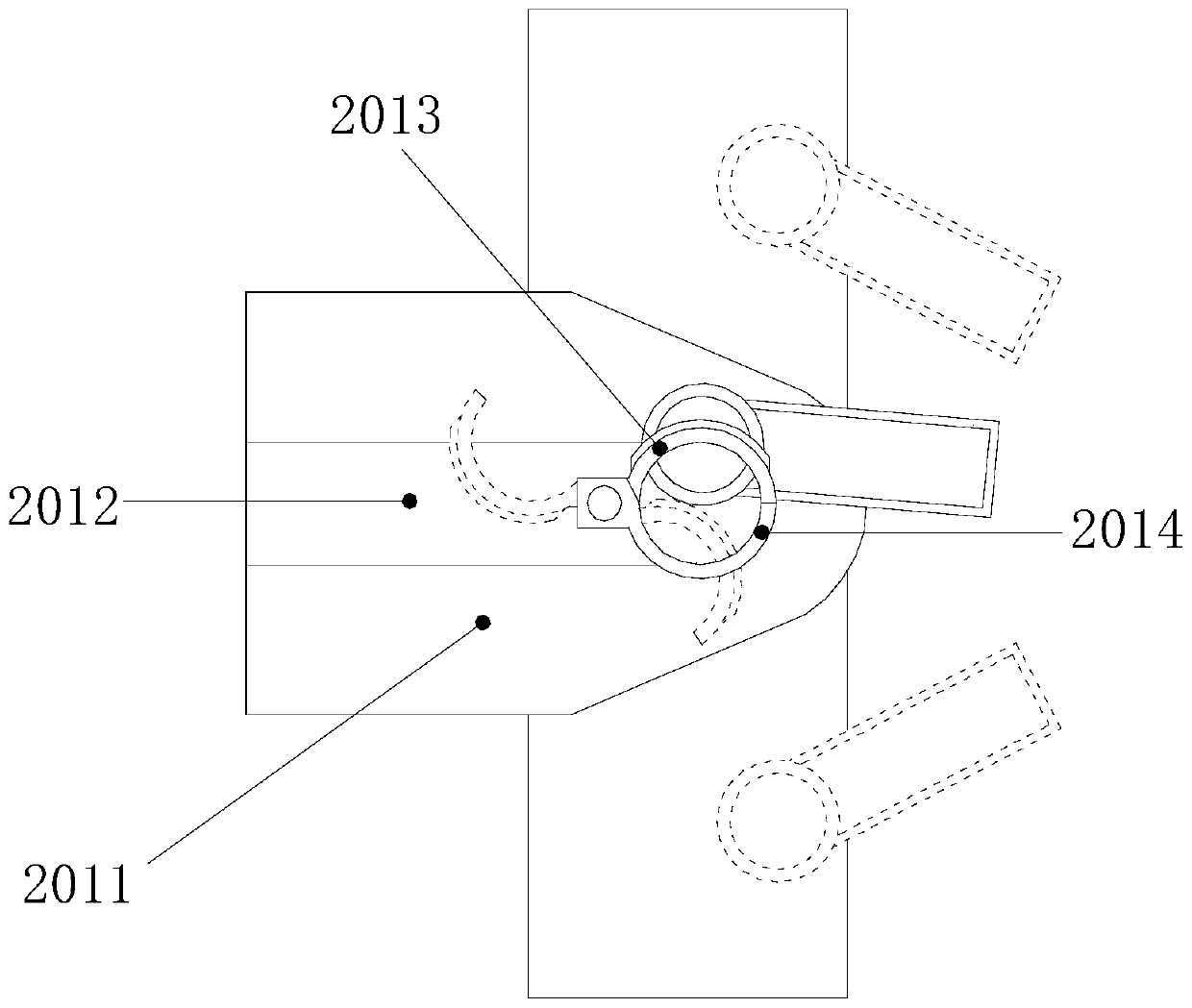

[0030] The processing chamber 2 includes a finished product exporter 201, an export base 202, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com