Sol preparation process and device for releasing dormant thelephora ganbajun

A preparation process and technology for dry bacteria, applied in the field of sol preparation, can solve the problems of low efficiency, long cycle of dry bacteria, restricting the utilization of precious resources of dry bacteria, etc., and achieve the effect of promoting repair and improving growth conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

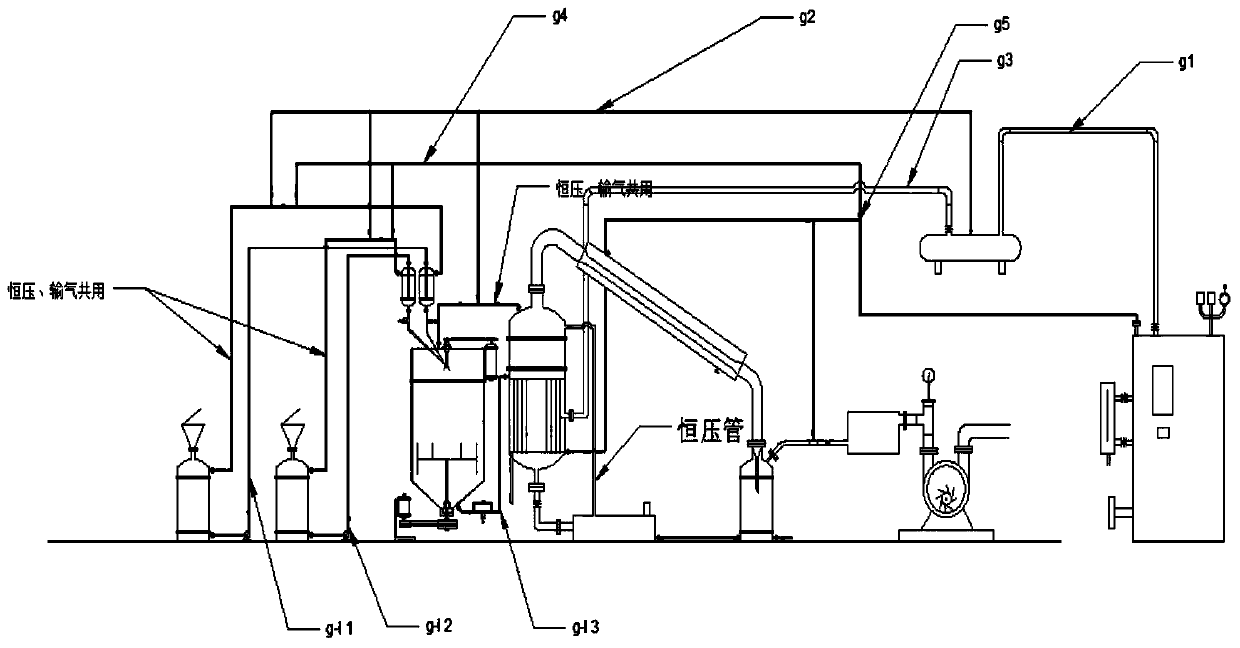

Image

Examples

Embodiment 1

[0036] Step 1: Use 400k, 250kpa high temperature and high pressure to kill the microorganisms in the natural rosin; then sterilize the preparation device, feed steam into the closed sterilization for three hours, adopt segmental sterilization during the sterilization process, close each outlet valve, The steam flow direction is regulated by the three-way air-throttle valve to form a loop for sterilization, the regulating valve on the pipeline of the diaphragm pump 18 is opened, and the air valve of the component mixing tank 20 is opened at the same time, and closed after sterilization;

[0037] Step 2: extract in advance according to the mass ratio of rosin: absolute ethanol = 120:900 to obtain a brown-yellow absolute ethanol rosin solution, and filter to remove the insoluble long-chain resin and pine needle weeds in the absolute ethanol rosin solution;

[0038] Step 3: Open the constant pressure pipeline valve j25 of the liquid delivery equipment, turn on the clean water pump ...

Embodiment 2

[0042] Step 1: use 410k, 251kpa high temperature and high pressure to kill the microorganisms in the natural rosin; then sterilize the preparation device, feed steam into the closed sterilization for three hours, adopt segmental sterilization during the sterilization process, close each outlet valve, The steam flow is regulated by the three-way air-throttle valve to form a loop for sterilization, and the regulating valve on the pipeline of the diaphragm pump 18 is opened, and the air valve of the component mixing tank 20 is opened at the same time, and closed after sterilization;

[0043] Step 2: extract in advance according to the mass ratio of rosin: absolute ethanol = 135:920 to obtain a brown-yellow absolute ethanol rosin solution, and filter to remove the insoluble long-chain resin and pine needle weeds in the absolute ethanol rosin solution;

[0044]Step 3: Open the constant pressure pipeline valve j25 of the liquid delivery equipment, turn on the clean water pump 3, add ...

Embodiment 3

[0048] Step 1: use 425k, 252kpa high temperature and high pressure to kill the microorganisms in the natural rosin; then sterilize the preparation device, feed steam into the closed sterilization for three hours, adopt segmental sterilization during the sterilization process, close each outlet valve, The steam flow direction is regulated by the three-way air-throttle valve to form a loop for sterilization, the regulating valve on the pipeline of the diaphragm pump 18 is opened, and the air valve of the component mixing tank 20 is opened at the same time, and closed after sterilization;

[0049] Step 2: extract in advance according to the mass ratio of rosin: absolute ethanol = 144:950 to obtain a brown-yellow absolute ethanol rosin solution, and filter to remove the insoluble long-chain resin and pine needle weeds in the absolute ethanol rosin solution;

[0050] Step 3: Open the constant pressure pipeline valve j25 of the liquid delivery equipment, turn on the clean water pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com