3D printed lower limb prosthetic socket liner and manufacturing method thereof

A 3D printing and manufacturing method technology, applied in medical science, prosthesis, improvement of process efficiency, etc., can solve problems such as poor resistance to compression deformation, atrophy of residual limbs, skin problems of residual limbs, etc., to increase the buffer effect , enhance comfort, improve the effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

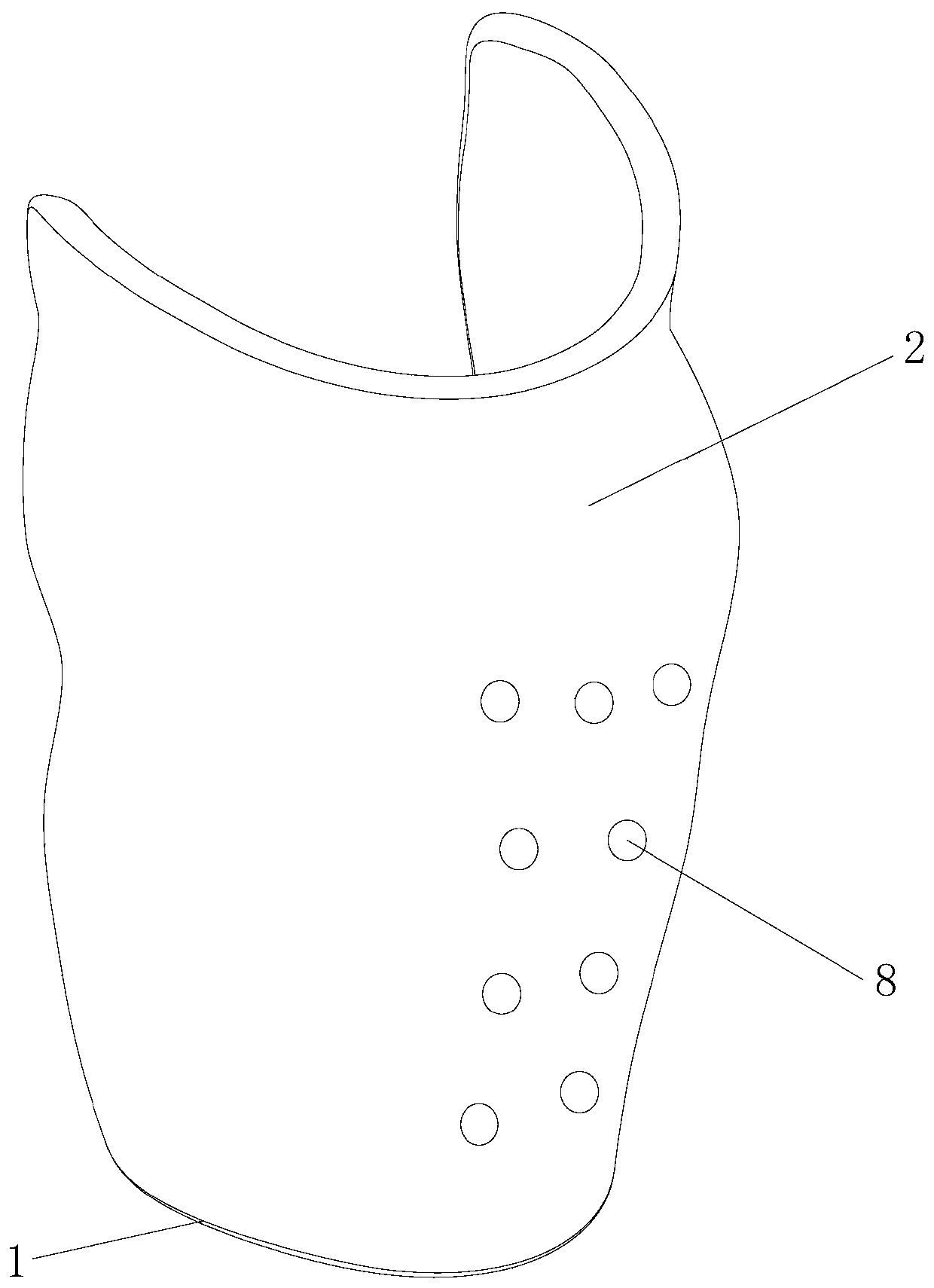

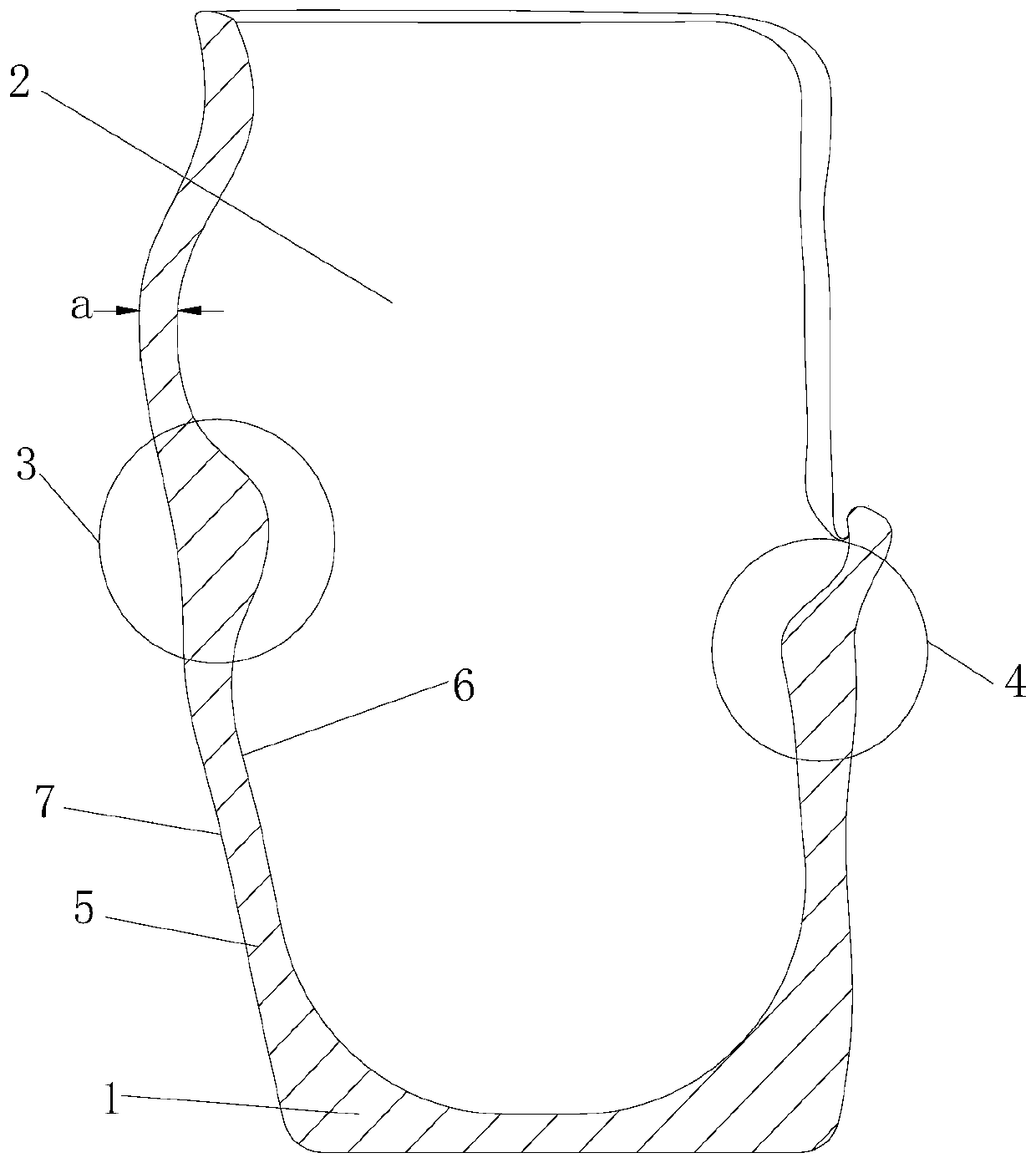

[0049] Such as Figure 1 to Figure 3 The shown 3D printed lower limb prosthetic socket inner liner includes a sleeve bottom and a sleeve body, both of which are made of elastomer materials, and the sleeve bottom and sleeve body are connected, and the sleeve body includes a The patellar tendon area corresponding to the patellar ligament and the popliteal fossa area corresponding to the popliteal fossa, the sleeve base, the patellar tendon area and the popliteal fossa area are all increased in thickness. The size of the increased thickness is 1 mm to 10 mm. The increased thickness in this embodiment is preferably 4 mm. This increase in thickness is beneficial to increase the cushioning effect when the patient walks, the wearing comfort and the suspension effect of the prosthesis. In order to ensure the connection tightness of the sleeve in the socket, the sleeve bottom and the sleeve body are integrated, that is, the connection between the sleeve bottom and the sleeve body is ...

Embodiment 2

[0066] The 3D printed lower limb prosthetic socket inner liner in this embodiment is the same as that of Embodiment 1 except for the following technical features: Figure 8 As shown, the filling structure in this embodiment is a honeycomb filling structure, and this structure ensures good stability and strength of the lining in the socket.

Embodiment 3

[0068] The 3D printed lower limb prosthetic socket inner liner in this embodiment is the same as that of Embodiment 1 except for the following technical features: Figure 9 As shown, the filling structure in this embodiment is a circular filling structure. The circular filling structure is to increase the elastic effect in the circumferential direction while maintaining the strength of the inner liner in the vertical direction (perpendicular to the ground direction).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com