Forage mulberry, microbial fermentation method, mutton sheep concentrate supplement and preparation method

A technology of microbial fermentation and concentrate supplementary material, which is applied in the field of mutton sheep concentrate supplementary material and preparation, protein mulberry and microbial fermentation, can solve the problem of inability to eliminate or reduce the adverse effects of crude fiber, affect digestion and absorption, metabolism, and limit the utilization of protein mulberry To achieve the effect of regulating the immune function of animals, high nutritional content and digestibility, and good palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

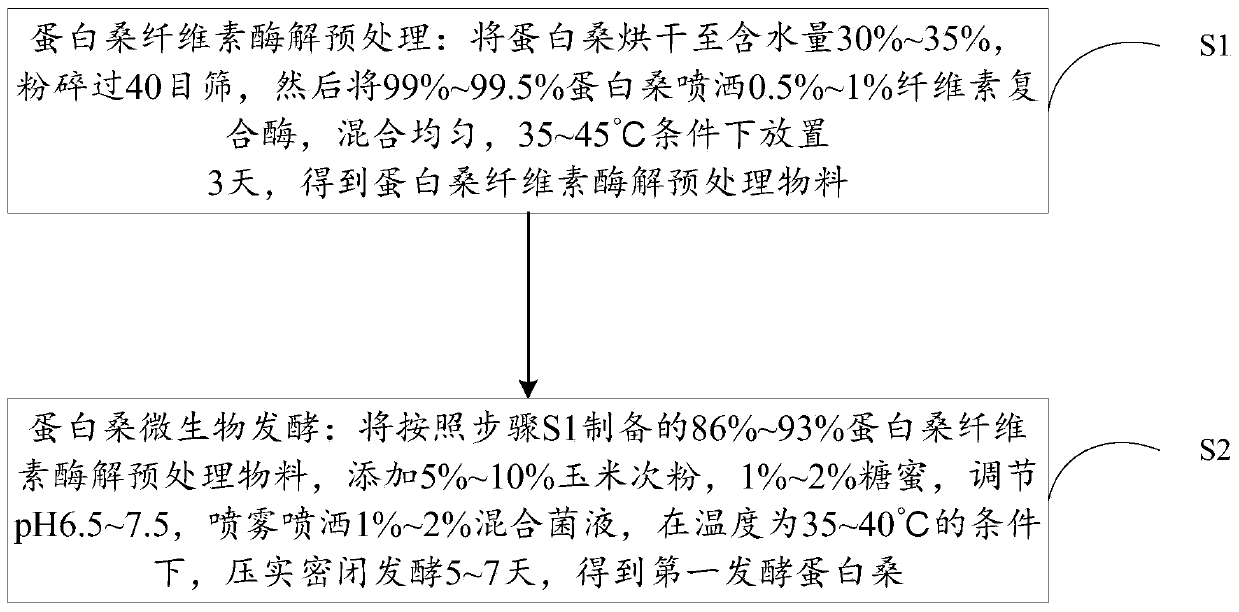

[0037] Example 1 of the present application discloses a microbial fermentation method for protein mulberry, see figure 1 ,include:

[0038] S1. Protein mulberry cellulose enzymatic hydrolysis pretreatment: dry the protein mulberry to a water content of 30%-35%, crush it through a 40-mesh sieve, and then spray 99%-99.5% protein mulberry with 0.5%-1% cellulose compound enzyme , mixed evenly, and placed under the condition of 35-45° C. for 3 days to obtain the protein mulberry cellulose enzymatic hydrolysis pretreatment material.

[0039] S2. Protein mulberry microbial fermentation: add 5% to 10% corn flour and 1% to 2% molasses to the 86% to 93% protein mulberry cellulose enzymolysis pretreatment material prepared according to step S1, and adjust the pH to 6.5 to 6.5% 7.5, spraying 1%-2% mixed bacterial solution, and under the condition of temperature of 35-40° C., compacting and sealing fermentation for 5-7 days to obtain the first fermented protein mulberry.

[0040] Wherein...

Embodiment 2

[0045] Embodiment 2 of the present application discloses a protein mulberry. The raw material components of the protein mulberry include: 86%-93% protein mulberry cellulose enzymatic hydrolysis pretreatment material, 5%-10% corn secondary flour, 1%-2 % molasses and 1% to 2% mixed bacterial solution;

[0046] Wherein, the protein mulberry cellulose enzymatic hydrolysis pretreatment material includes 99%-99.5% protein mulberry and 0.5%-1% cellulose complex enzyme.

[0047] The raw material of described mixed bacterial liquid comprises: Candida utilis, Lactobacillus acidophilus and Bacillus subtilis, the living bacteria quantity composition ratio of Candida utilis, Lactobacillus acidophilus and Bacillus subtilis is (2- 4):(1-2):(1-2).

[0048] Specifically, the composition ratio of the number of live bacteria can be various, for example, Candida utilis: Lactobacillus acidophilus: the composition ratio of the number of live bacteria of Bacillus subtilis can be 2:1:1, 4:2:1, 3:2:...

Embodiment 3

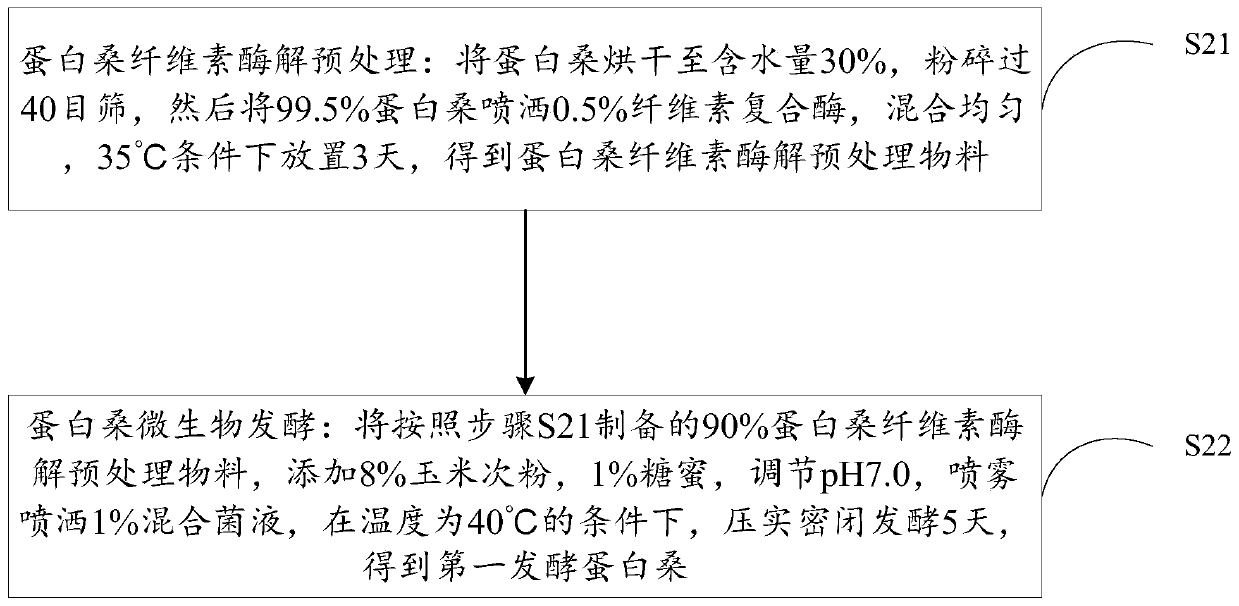

[0052] Example 3 of the present application discloses a microbial fermentation method for protein mulberry, see figure 2 ,include:

[0053] S21. Protein mulberry cellulose enzymatic hydrolysis pretreatment: dry the protein mulberry to a water content of 30%, crush it through a 40-mesh sieve, then spray 99.5% protein mulberry with 0.5% cellulose compound enzyme, mix well, and place it at 35°C After 3 days, the protein mulberry cellulose enzymatic hydrolysis pretreatment material was obtained.

[0054] S22. Protein mulberry microbial fermentation: add 8% corn flour and 1% molasses to the 90% protein mulberry cellulose enzymolysis pretreatment material prepared according to step S21, adjust the pH to 7.0, and spray 1% of the mixed bacterial solution on the Under the condition that the temperature is 40° C., compaction and airtight fermentation are carried out for 5 days to obtain the first fermented protein mulberry.

[0055] Wherein, the raw materials of the mixed bacterial s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com