Flexible electromagnetic wave shielding material, electromagnetic wave shielding type circuit module comprising same and electronic device furnished with same

一种屏蔽材料、电磁波的技术,应用在屏蔽材料、磁场/电场屏蔽、印刷电路等方向,能够解决柔软性不足、传导性涂层裂隙、剥离、难以表现柔软性、伸缩性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

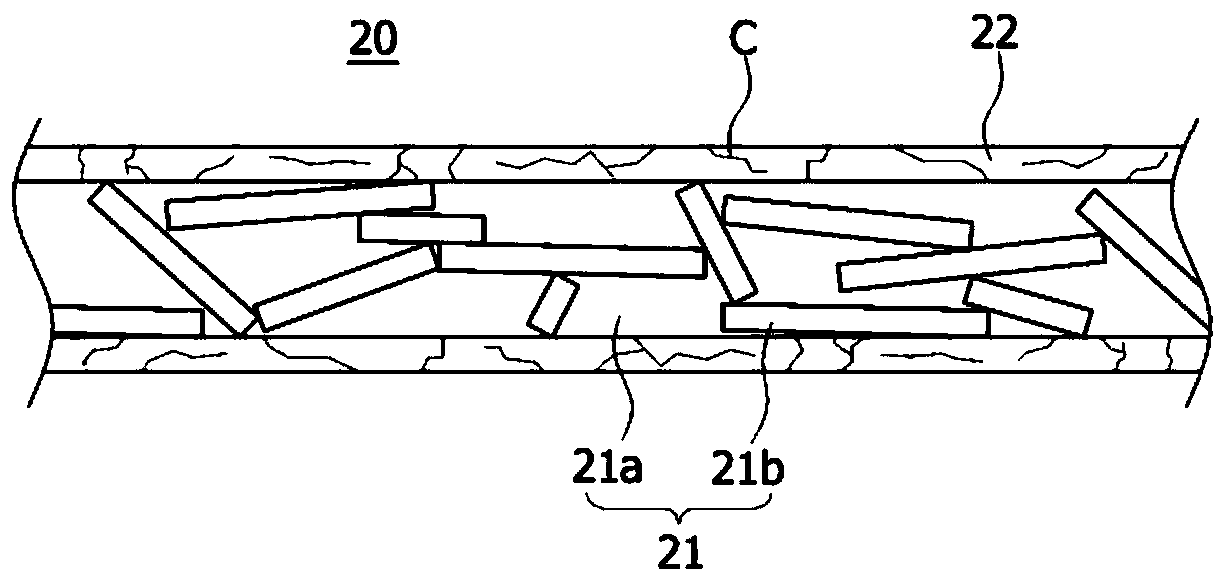

[0219] In 88 g of dimethylacetamide and acetone at a weight ratio of 70:30, 12 g of polyvinylidene fluoride was dissolved at a temperature of 80° C. for 6 hours using a magnetic bar to prepare a spinning solution. In the spinning solution, as a conductive filler, spherical silver particles with an average particle diameter of 1.3 μm are mixed so that the volume ratio of polyvinylidene fluoride to silver particles is 1:0.2, accounting for 16.7% of the total volume of the final fiber part, Then, it was dispersed for 12 hours using an ultrasonic disperser. Put the spinning solution into the solution tank of the electrospinning device, stir the solution with an impeller, and spit it out at a speed of 20 μl / min / hole. At this time, the temperature in the spinning section is kept at 30°C, the humidity is kept at 50%, the distance between the collector and the tip of the spinning nozzle is 20cm, and a high voltage generator is used to apply a voltage of 40kV to the spinning nozzle gro...

Embodiment 2~11

[0222] It carried out and produced similarly to Example 1, but as shown in Table 1 or Table 2 below, the content and particle diameter of a conductive filler were changed, and the conductive fiber web shown in Table 1 below was manufactured.

experiment example 1

[0226] The following physical properties were measured for the conductive webs of Examples 1 to 11 and Comparative Example 1, and are shown in Table 1 and Table 2 below.

[0227] 1. Initial electromagnetic wave shielding performance

[0228] The impedance of the surface of the conductive fiber web was measured by an impedance measuring instrument (Hiki 3540 mΩ HITESTER, Hiki Co., Ltd.). With the measured value of Comparative Example 1 being 100 as a reference, the measured impedance values of Examples are shown as relative percentages.

[0229] 2. Variation rate of electromagnetic wave shielding performance

[0230] Using jigs, stretch the test piece 1.2 times in the transverse direction, and then stretch it 1.2 times in the longitudinal direction, taking this as one group and repeating three groups.

[0231] Then, using the initial electromagnetic wave shielding performance measurement method, after obtaining the impedance value B of each test piece after stretching, accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com