Double-fed type electrically excited synchronous motor

A synchronous motor and electric excitation technology, which is applied to synchronous motors, electrical components, and electromechanical devices for single-phase currents, can solve problems such as low torque density, reduce thermal load, improve flexibility, and reduce cooling hardware The effect of equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment mainly introduces the situation that the primary iron core is composed of several primary iron core blocks along the circumferential direction.

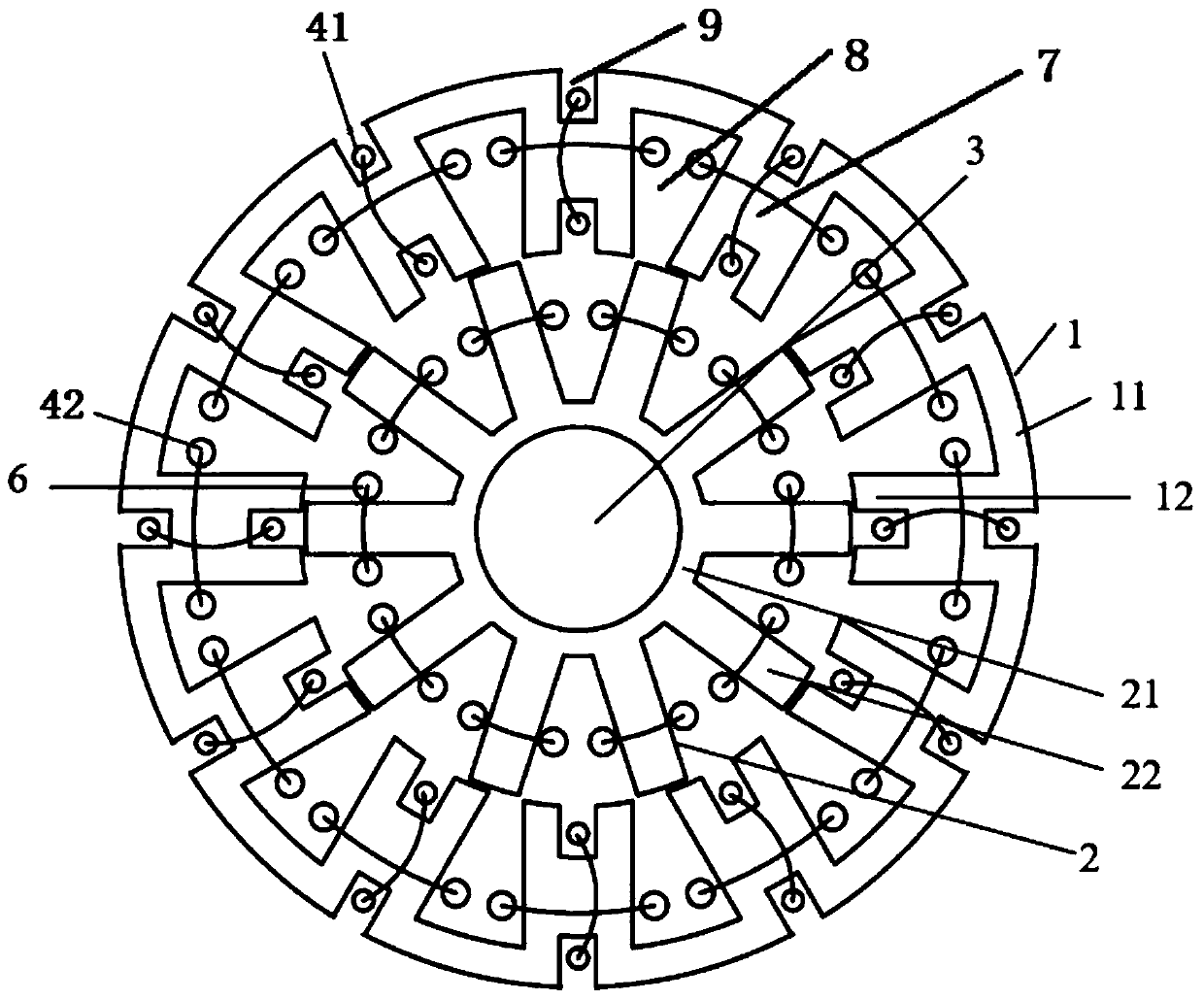

[0047] Such as figure 1 As shown, it is a double-fed electric excitation synchronous motor with primary twelve slots / secondary ten slots, including primary, secondary and shaft 3: the primary is located outside the secondary; the secondary is fixed on shaft 3; the primary includes the primary Iron core 1, excitation winding 41 and primary armature winding 42; wherein, primary iron core 1 is made up of twelve primary iron core blocks, and two adjacent primary iron core blocks are connected by magnetic bridge 7; each A primary iron core block includes a primary iron core yoke 11 and a primary iron core tooth 12;

[0048] The first primary iron core slot 8 and the second primary iron core slot 9 are formed between the primary iron core teeth 12, wherein the first primary iron core slot 8 refers to the slot inside...

Embodiment 2

[0063] Unlike the primary iron core 1 in Embodiment 1 which is a block-combined structure, this embodiment mainly introduces the case where the primary iron core has an integrated structure.

[0064] Such as Figure 7 As shown, it is a doubly-fed electric excitation synchronous motor with primary six slots / secondary four slots,

[0065] In this solution, the primary winding 4 serves both as an excitation winding and as an armature winding. The primary winding 4 adopts a double-layer centralized armature winding, and the secondary winding 6 adopts a single-layer distributed armature winding. The two sides of the primary coil are placed in two adjacent primary core slots, the secondary slots where the two sides of the secondary coil are located are two teeth apart, one secondary slot, and two primary coils separated by half a circle in series to form a primary winding of one phase. In this solution, the secondary is the rotating part, and the secondary winding 6 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com