PIN needle position degree detection method for large-size product with sub-pixel precision

A detection method and sub-pixel technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of unsatisfactory measurement accuracy, long measurement time, poor accuracy, etc., to facilitate tracking and analysis, reduce errors, and realize storage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions protected by the present invention will be specifically described below in conjunction with the accompanying drawings.

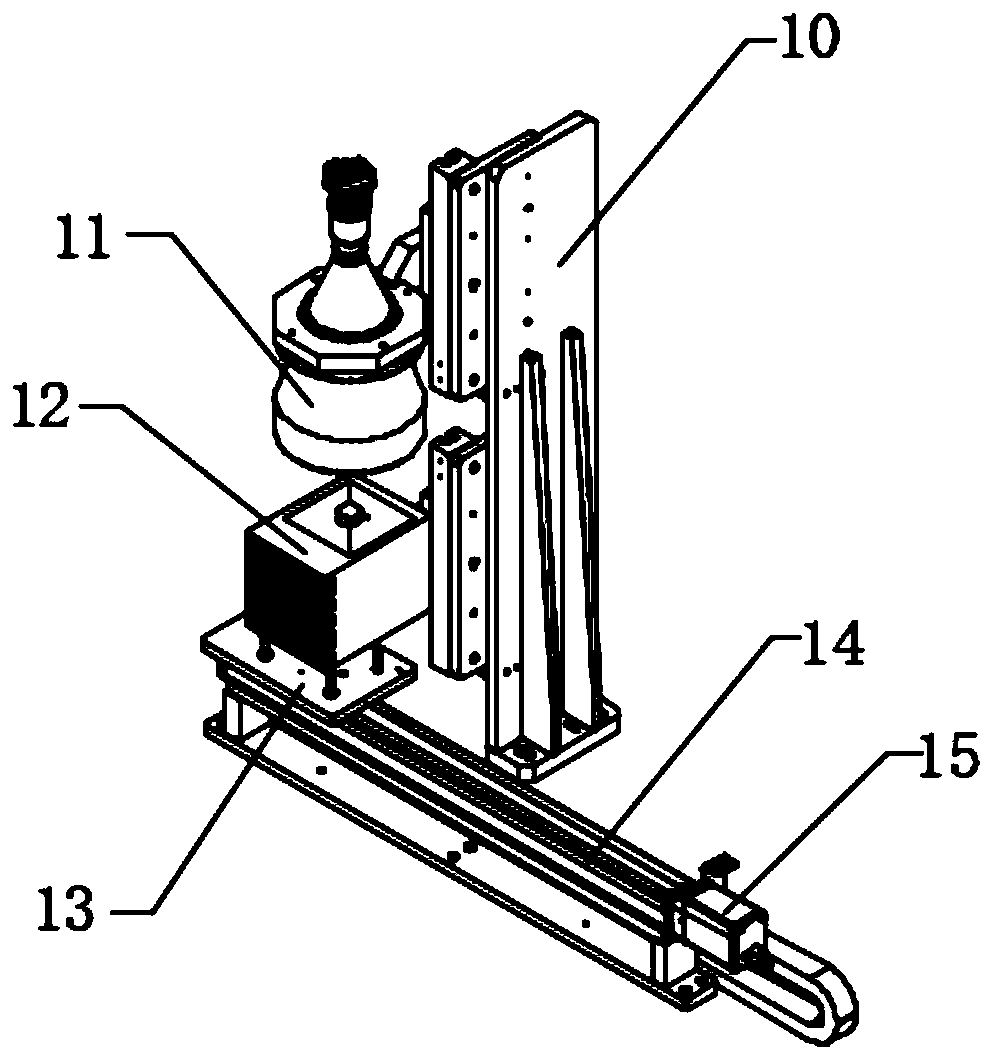

[0047] Please refer to figure 1 . The PIN pin position detection method for large-size products with sub-pixel precision proposed by the present invention is realized by a PIN pin detection system. The PIN pin detection system includes a hardware part and a software part, wherein the hardware part includes a PIN pin detection device and an industrial computer. , the software part runs on the industrial computer, and the industrial computer controls the work of the PIN needle detection device, and processes, stores and displays the images and data acquired by the PIN needle detection device.

[0048] Described PIN pin detection equipment comprises servo system, light source 12 and camera 11, wherein, light source 12 is arranged on the top of servo system, and described camera 11 is arranged on the top of described light source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com