Sliding plate supported type non-through shaft plunger pump or motor

A plunger pump, supported technology, applied in the field of sliding plate supported non-through-shaft plunger pump or motor, to achieve the effect of reducing the cost of use, less maintenance in the later period, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

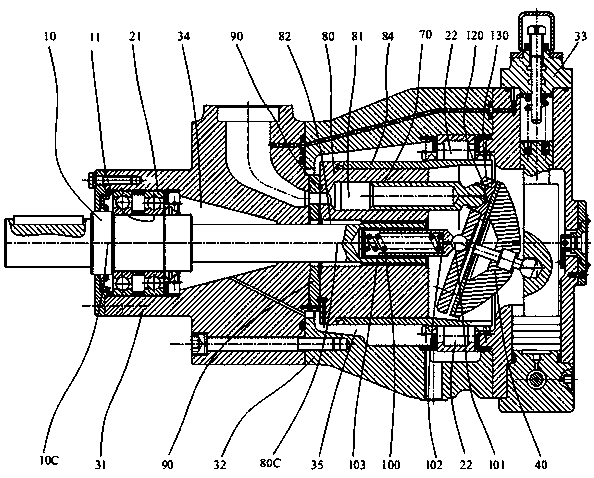

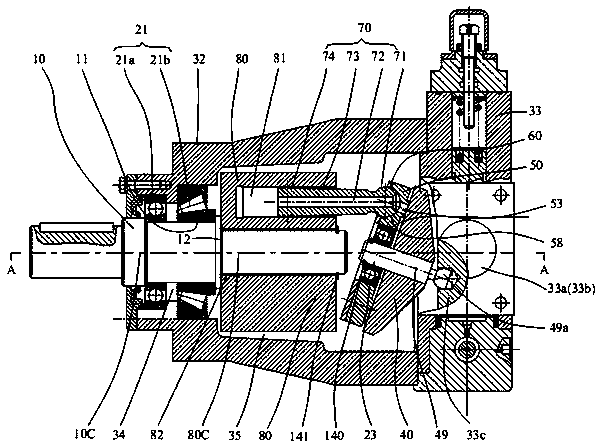

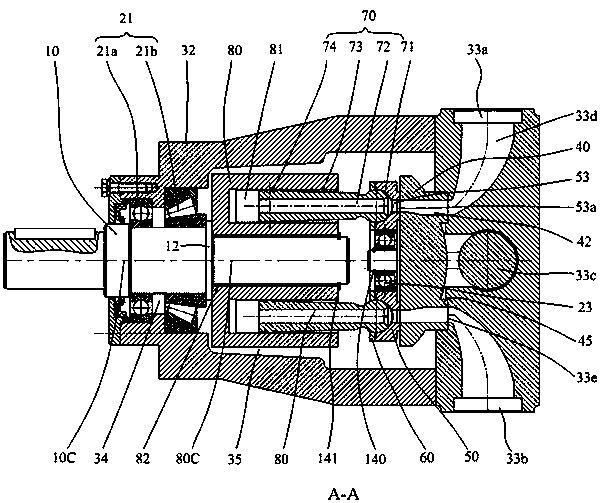

[0043] like Figure 2-9 Shown is an embodiment of the sliding plate supported non-through shaft plunger pump of the present invention. In the preferred embodiment shown, the axial plunger pump includes a main shaft 10, a housing, a first bearing 21, a bevel Disc 40, sliding plate 50, plunger 70 and cylinder 80, the spindle axis 10C of the said main shaft 10 coincides with the cylinder central axis 80C of said cylinder 80, one end of said main shaft 10 protrudes out of the housing and supports On the first bearing 21, the other end of the main shaft 10 cantilever supports the cylinder body and is connected with the cylinder body 80 through a key. The sliding plate 50 is supported on the swash plate 40 and is closely matched with the working surface of the swash plate 40. One end of the sliding plate 50 is provided with a plurality of waist-shaped oil chambers 53a, and the other end surface of the sliding plate 50 is provided with a plurality of plunger ball sockets 58, and the ...

Embodiment 2

[0067] like Figure 10 As shown, the main difference from Embodiment 1 is that a flow distribution plate 90 is interposed between the sliding plate 50 and the swash plate 40 in the sliding plate pair, and the static pressure bearing surface 51 is supported on the flow distribution plate 90 and is connected with the flow distribution plate 90 Keeping the sliding fit, the distribution plate is fixed on the swash plate by means of pins, etc., and the distribution plate 90 is provided with a high-pressure distribution port 93 and a low-pressure distribution port 92, such as Figure 11 As shown, the high-pressure distribution port 93 and the low-pressure distribution port 92 communicate with the low-pressure distribution window 43 and the high-pressure distribution window 44 on the swash plate respectively. The low-pressure distribution port 92 and the high-pressure distribution port 93 can be arranged in a symmetrical or asymmetrical structure relative to the central plane, for ex...

Embodiment 3

[0070] like Figure 12 and 13 As shown, the main difference from other embodiments is that the sliding plate of the sliding plate supported non-through-shaft plunger pump or motor adopts an external support method, and the outer peripheral portion of the swash plate is provided with a support stop portion 41a, and the sliding plate 50 A third bearing 23 is interposed between the outer side and the inner side of the support stop portion 41a, and the sliding plate 50 is supported on the third bearing 23 in a radially constrained state. When the main shaft 10 and the cylinder body 80 are rotating, The plunger 70 reciprocates in the plunger cavity of the cylinder body 80 to realize oil suction and discharge of the pump or motor.

[0071] Likewise, the return structure of the axial piston pump or motor includes a restricting device on one side of the flow distribution sliding plate pair, and the restricting device restricts the sliding plate 50 away from the end surface of the swa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com