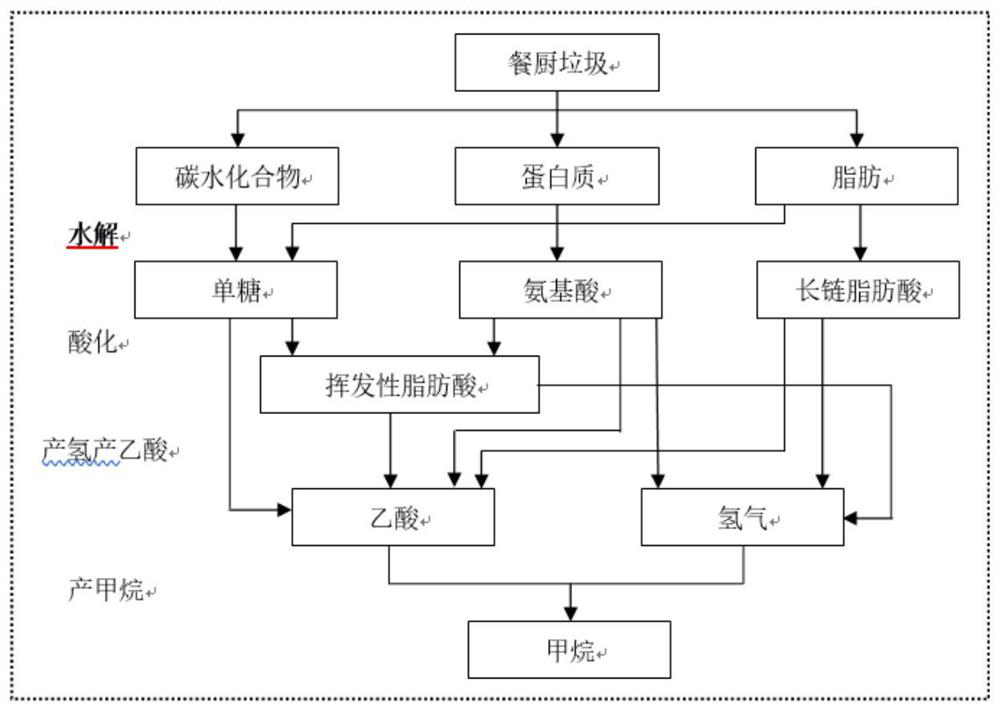

Method for fast biogas production from kitchen waste

A kitchen waste and rapid technology, which is applied in the field of rapid biogas production of kitchen waste, can solve the problems of reducing the specific surface area of contact between substrates and microorganisms, affecting the efficiency of methane production, and increasing the cost of methane production, so as to achieve resource utilization and high efficiency. Economic benefits and low cost investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

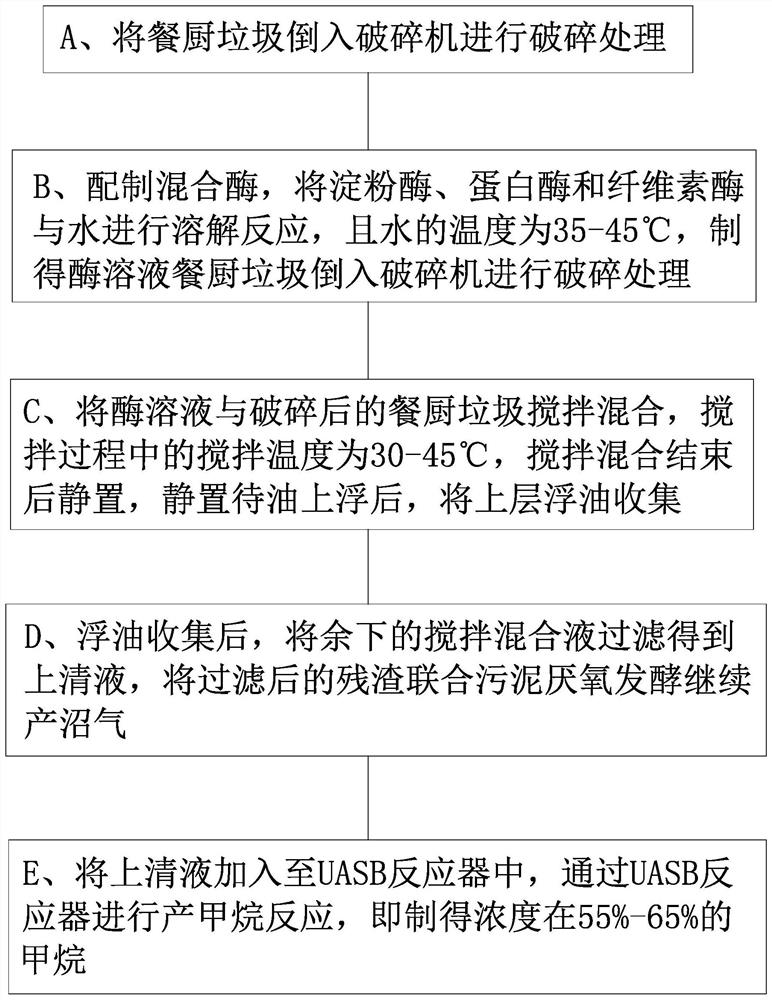

[0065] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0066] Such as Figure 2-3 as shown,

[0067] The fast biogas production method of kitchen waste comprises the following steps:

[0068] A. Pour 10kg of kitchen waste into the crusher for crushing;

[0069] B. Prepare a mixed enzyme, dissolve and react amylase, protease and cellulase with water, and the temperature of the water is 35-45°C to obtain an enzyme solution;

[0070] C. Stir and mix the enzyme solution with the broken kitchen waste. The stirring temperature during the stirring process is 30-45°C. After the stirring and mixing is completed, let it stand still. After the oil floats, collect the upper layer of slick oil;

[0071] D. After the oil slick is collected, filter the remaining stirred mixture to obtain the supe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com