Intelligent automatic loading and unloading poultry transporting vehicle

A technology for automatic loading and unloading and transport vehicles, which is applied in animal transportation, parallel-carrying vehicles, transportation and packaging, etc. The effect of avoiding physical injury and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

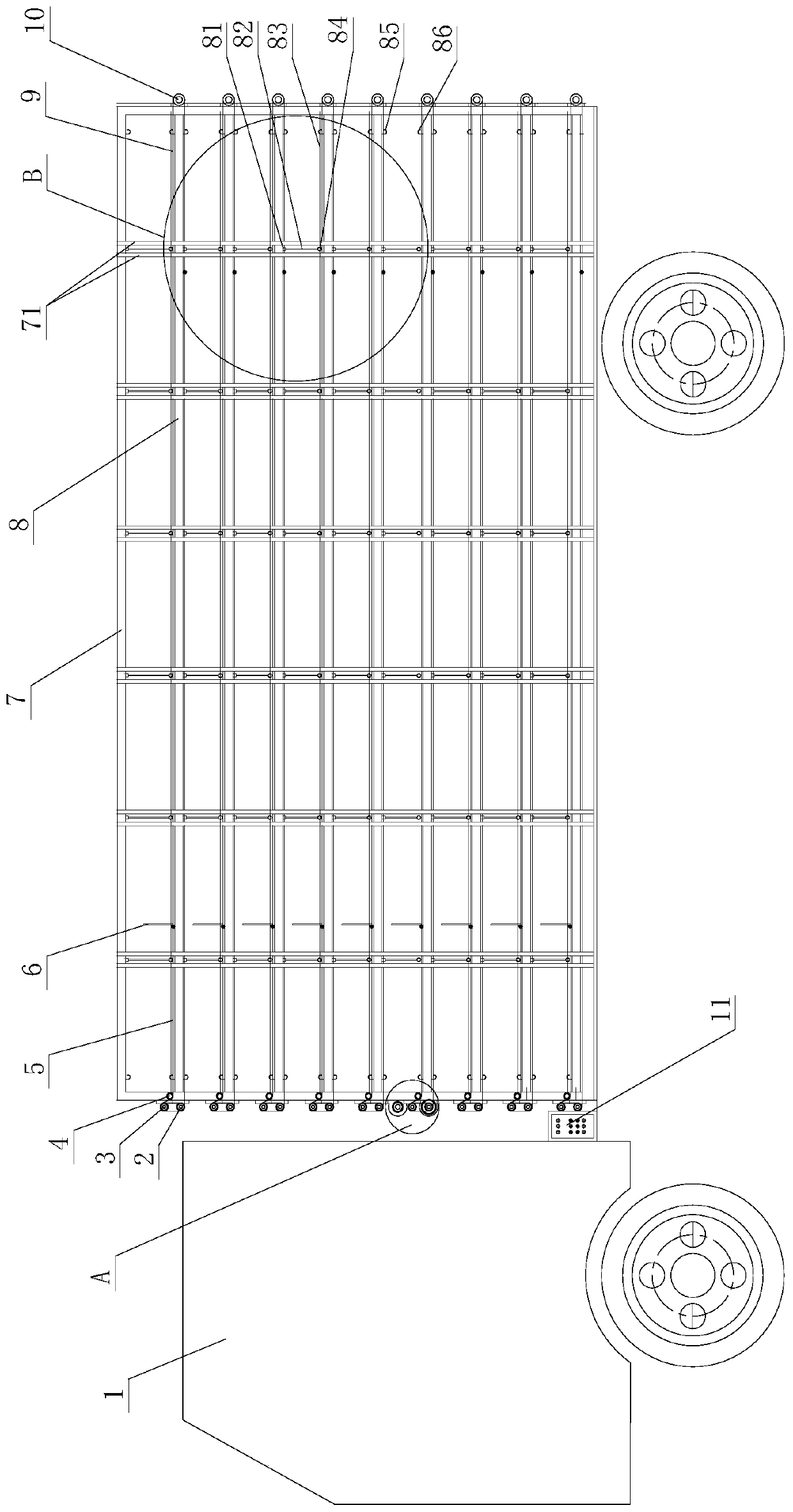

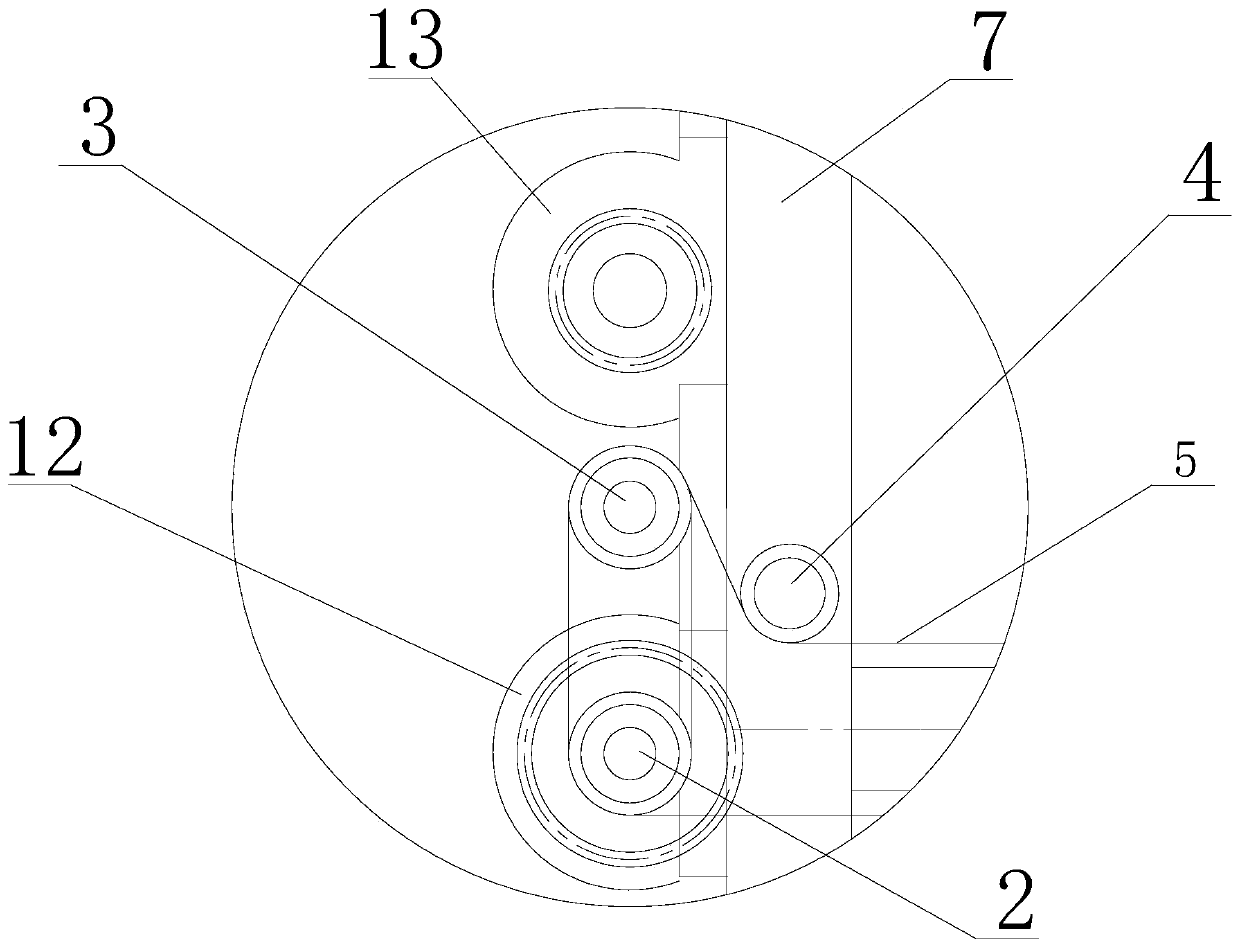

[0024] refer to Figure 1-5 The intelligent automatic loading and unloading poultry transport vehicle described in this embodiment includes a transport vehicle 1 and a poultry loading device assembled on the transport vehicle 1. Described poultry loading device comprises the main frame body 7 of multilayer frame structure, several groups are assembled in the loading and unloading mechanism in the main frame body, the driving device that drives loading and unloading mechanism work, and the intelligent controller 11 that controls driving device work. The bottom of described main frame body 7 is fixed on the car body flat plate of carrier vehicle 1, and main frame body 7 is evenly provided with the shelf 8 of several layers from top to bottom, and each layer of shelf 8 is correspondingly equipped with a set of unloading mechanism.

[0025] The loading and unloading mechanism includes a loading and unloading belt 9 and a traction drive device that drives the loading and unloading ...

Embodiment 2

[0044] refer to Image 6 , Figure 7 , compared with Embodiment 1, the difference of this embodiment is that the traction driving device is optimized, the traction rope 5 is replaced by a traction chain 5A, the traction sheave 18 on the driving roller 2 is replaced by a chain wheel 18A, and the The tension roller 3 and the traction sheave on the tension roller 3 are provided. Adopt the combination of sprocket wheel 18A and traction chain 5A, stability is better, can prevent the generation of skidding phenomenon. Specifically:

[0045] The traction driving device includes two parallel traction chains 5A, a driving roller 2 and a driven roller 10 . The front side of the main frame body 7 is fixed with two longitudinal brackets 17, and the two ends of the driving roller 2 are respectively installed on the two longitudinal brackets 17 through the bearing seat, and the two ends of the driving roller 2 are respectively fixed with Chain pulley 18A; said driven roller 10 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com