Uncoiling and arranging device for sheet tobacco pleat cutter

A sorting device and unwinding device technology, which is applied in the fields of tobacco, thin material processing, and tobacco preparation, can solve the problems of high production cost, long downtime, cumbersome operation, etc., reduce the number of downtime and downtime, and improve production efficiency , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

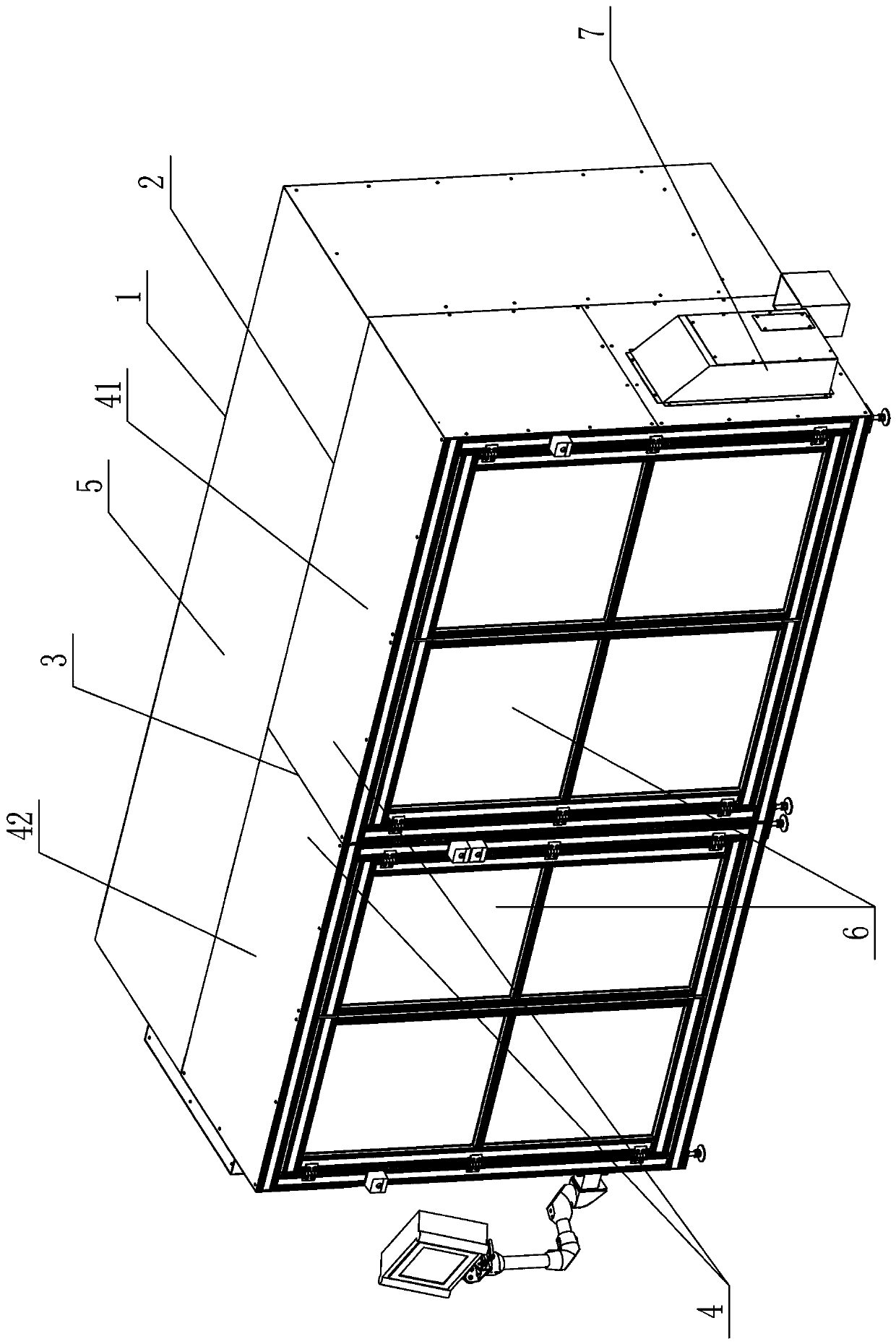

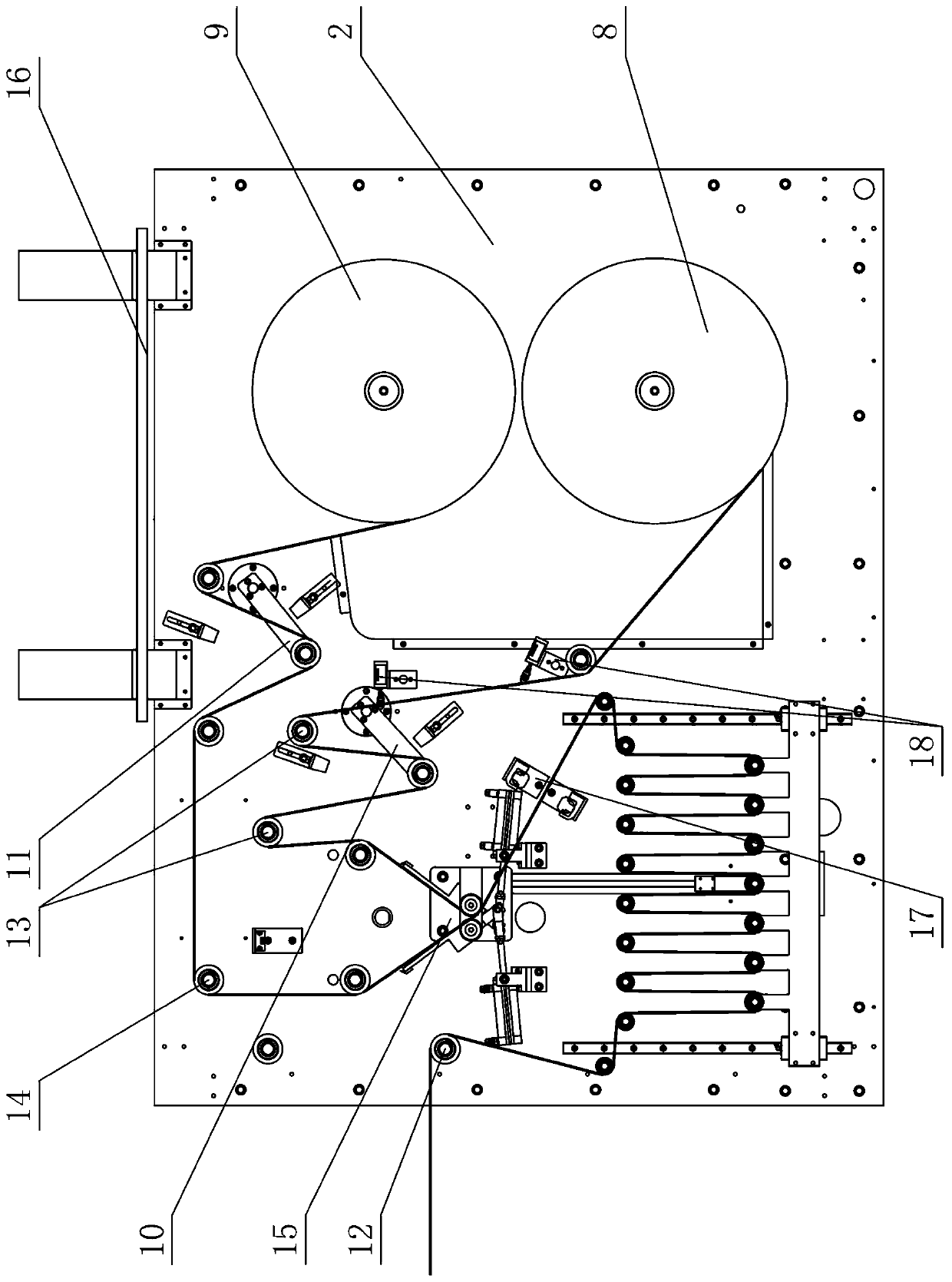

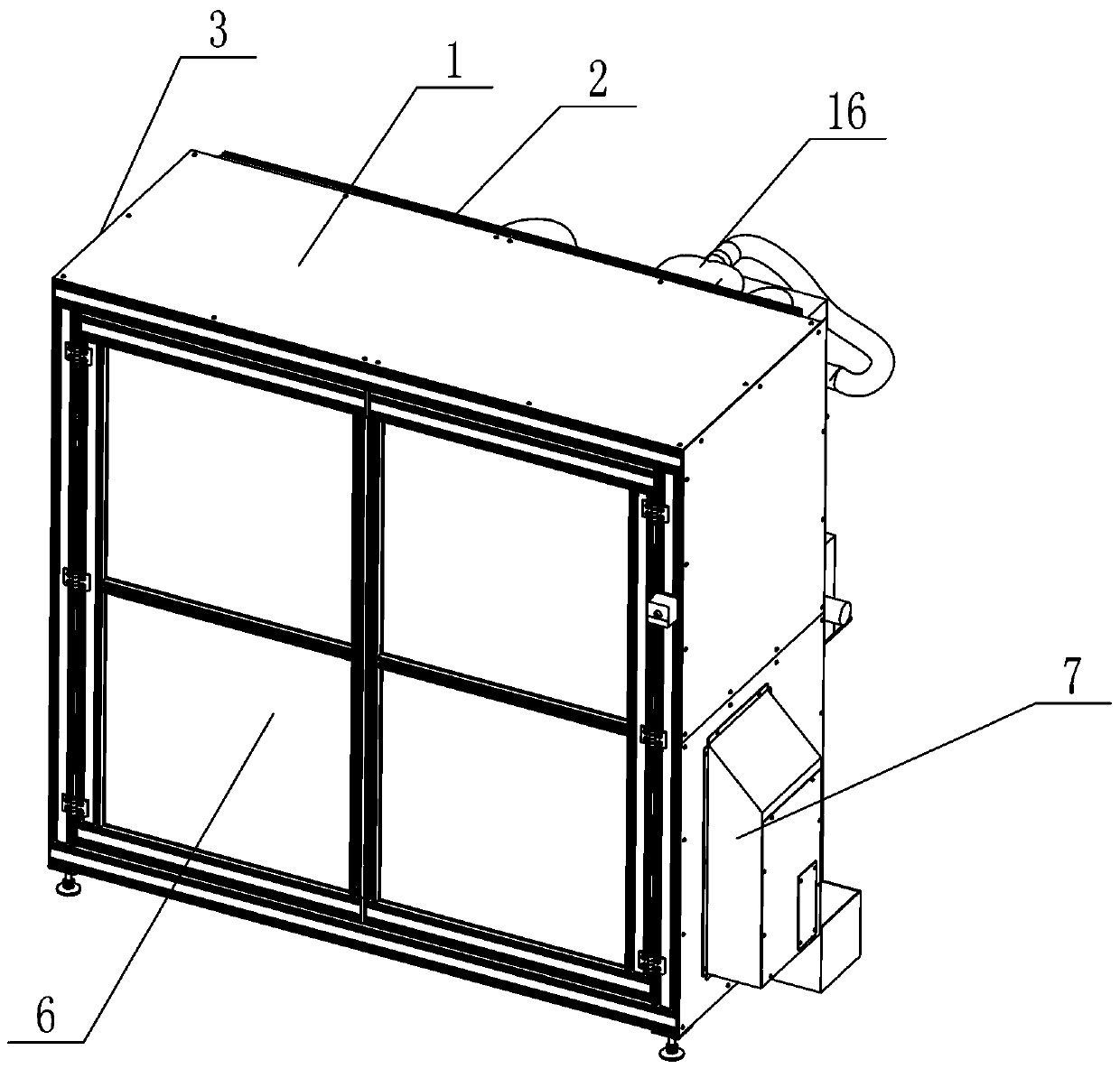

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0044] Such as Figure 1~6 As shown, a kind of uncoiling finishing device of sheet tobacco pleating machine, described sheet tobacco pleating machine comprises box body 1, wallboard 2 and partition board 3, described box body 1 is provided with wallboard 2, wall The board 2 is arranged along the length direction of the box body 1, and the wall board 2 divides the inner cavity of the box body 1 into a working chamber 4 and a power chamber 5. A partition 3 is arranged in the working chamber 4, and the partition 3 is arranged along the The height direction of the box body 1 is arranged, and the partition plate 3 divides the working chamber 4 into a finishing cavity 41 and a forming cavity 42. The partition plate 3 is provided with through holes, and the finishing cavity 41 and the forming cavity 42 are communicated through the through holes. A safety door 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com