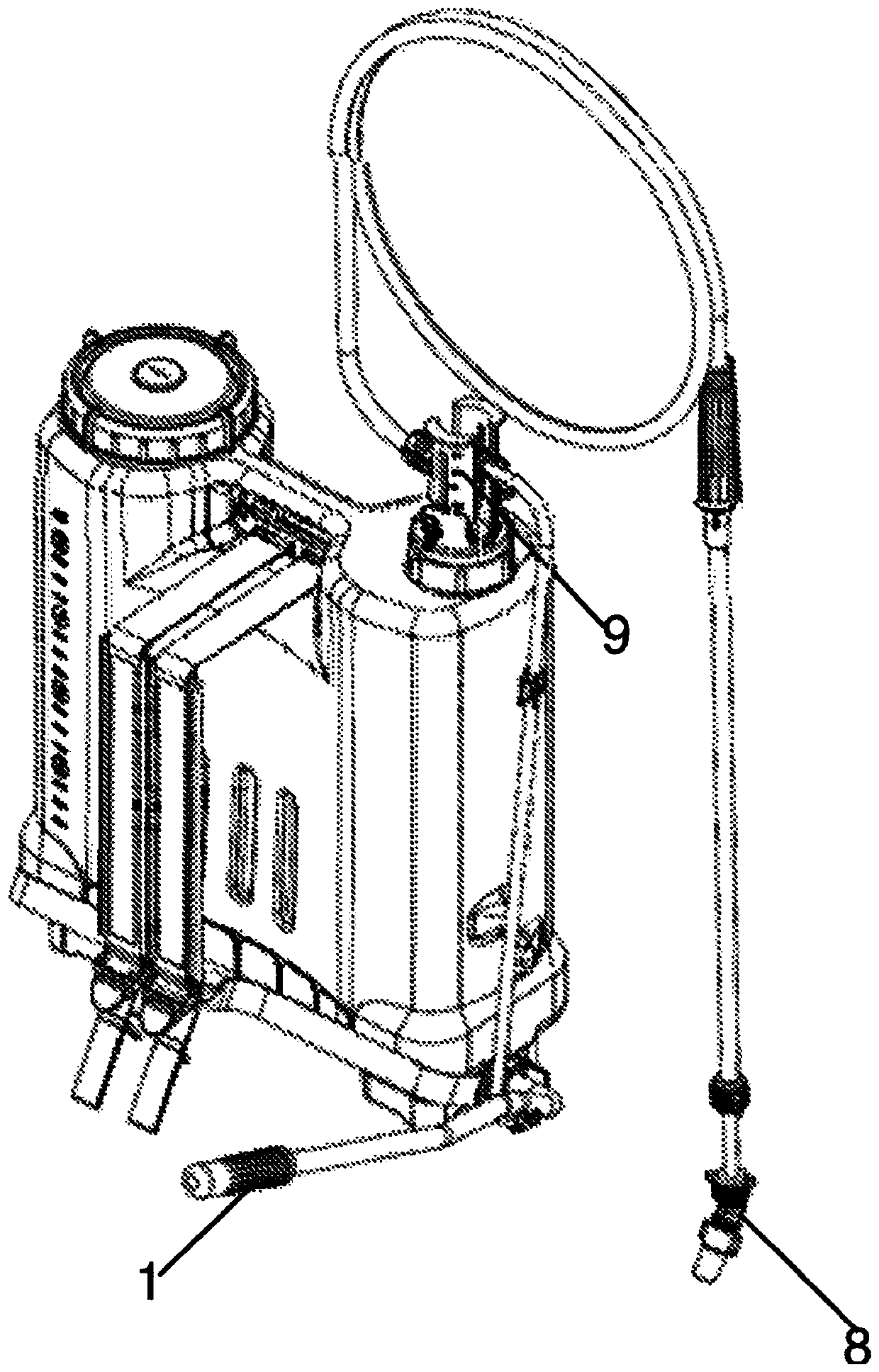

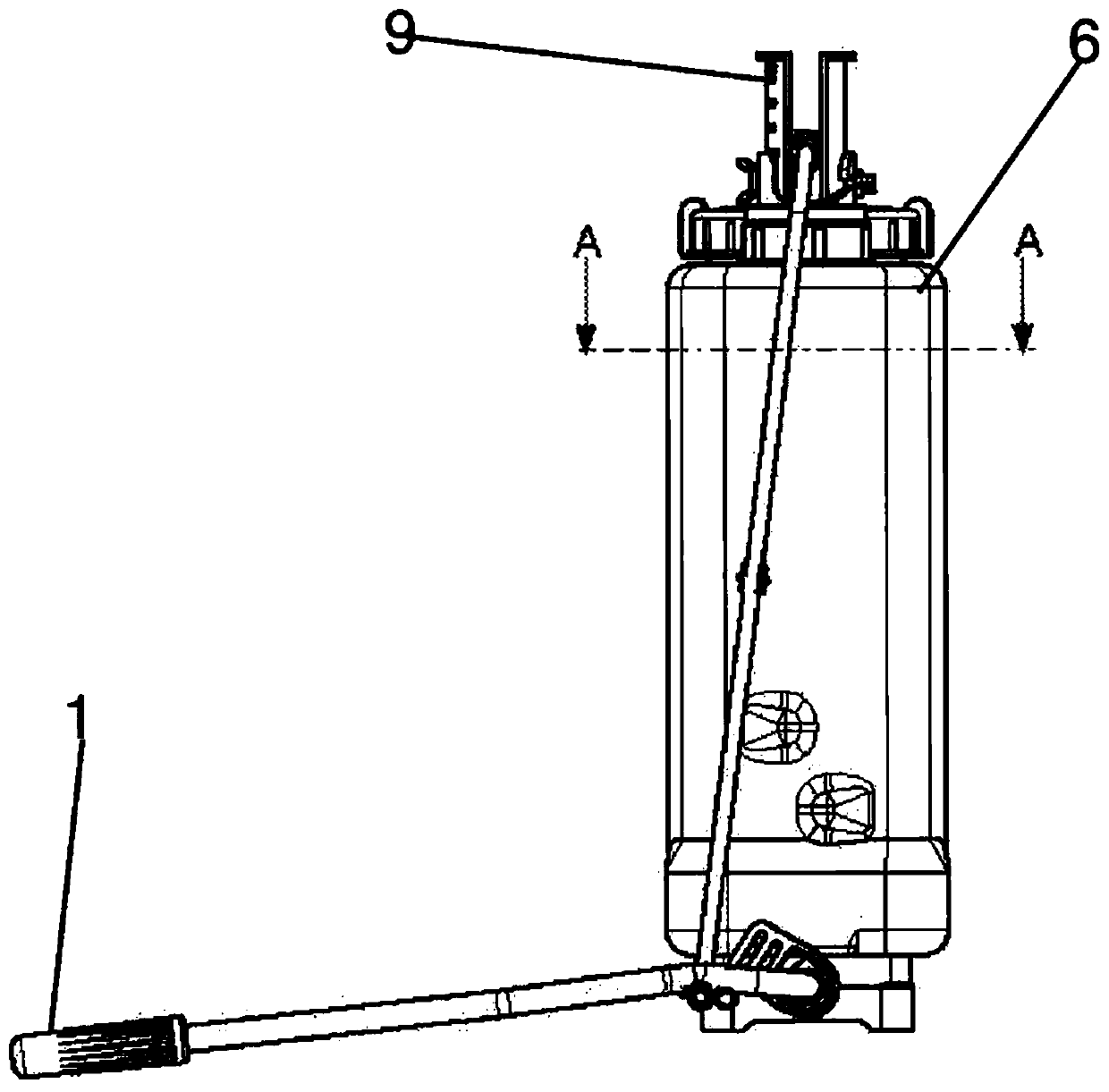

Liquid dosing device capable of being attached to hand sprayers with a piston pump system

A sprinkler and piston pump technology, which is applied in the field of volume metering devices, can solve the problems of ergonomically inappropriate working positions, unsuitable back sprayers, uncomfortable positions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

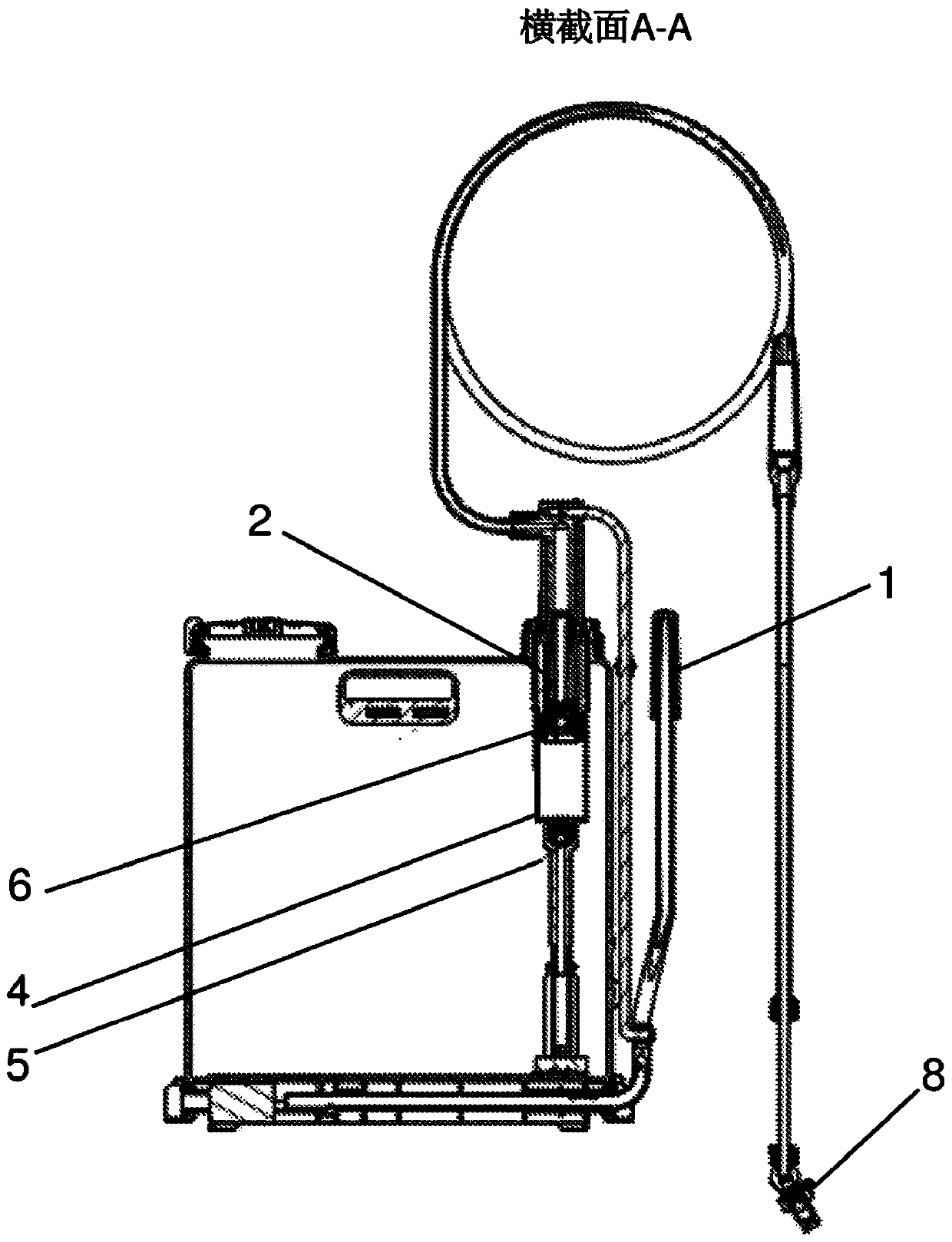

[0037] Operation of the system, suction / entry of liquids and spraying:

[0038] With the device filled and ready for use, the upward movement transmitted by the lever (1) causes the piston assembly (2) and plunger (3) to move upwards relative to the cylindrical cavity (4), causing the valve (5) to open And the liquid is sucked from the tank (6), allowing it to enter the cylinder; as Figure 4 location shown. When the downward movement of the lever (1) is applied, the piston (2) equipped with the plunger (3) compresses the liquid found inside the cylinder, and the rise of force towards the mass of the liquid produces the opposite force. Since it has an orifice with a valve in the center of the plunger (3), the liquid pulls upwards on this valve (7) - the area of least resistance - and the liquid enters the discharge circuit under pressure; the increased pressure in the cylinder Moment, at the end of the entry, the upward movement of the lever (1) resumes and the valve (7) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com