Internally coolable component for a gas turbine with at least one cooling duct

一种内部冷却、冷却通道的技术,应用在发动机元件、发动机功能、发动机的冷却等方向,能够解决叶片损坏等问题,达到降低压力损耗、低流动阻力、不降低冷却效果的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

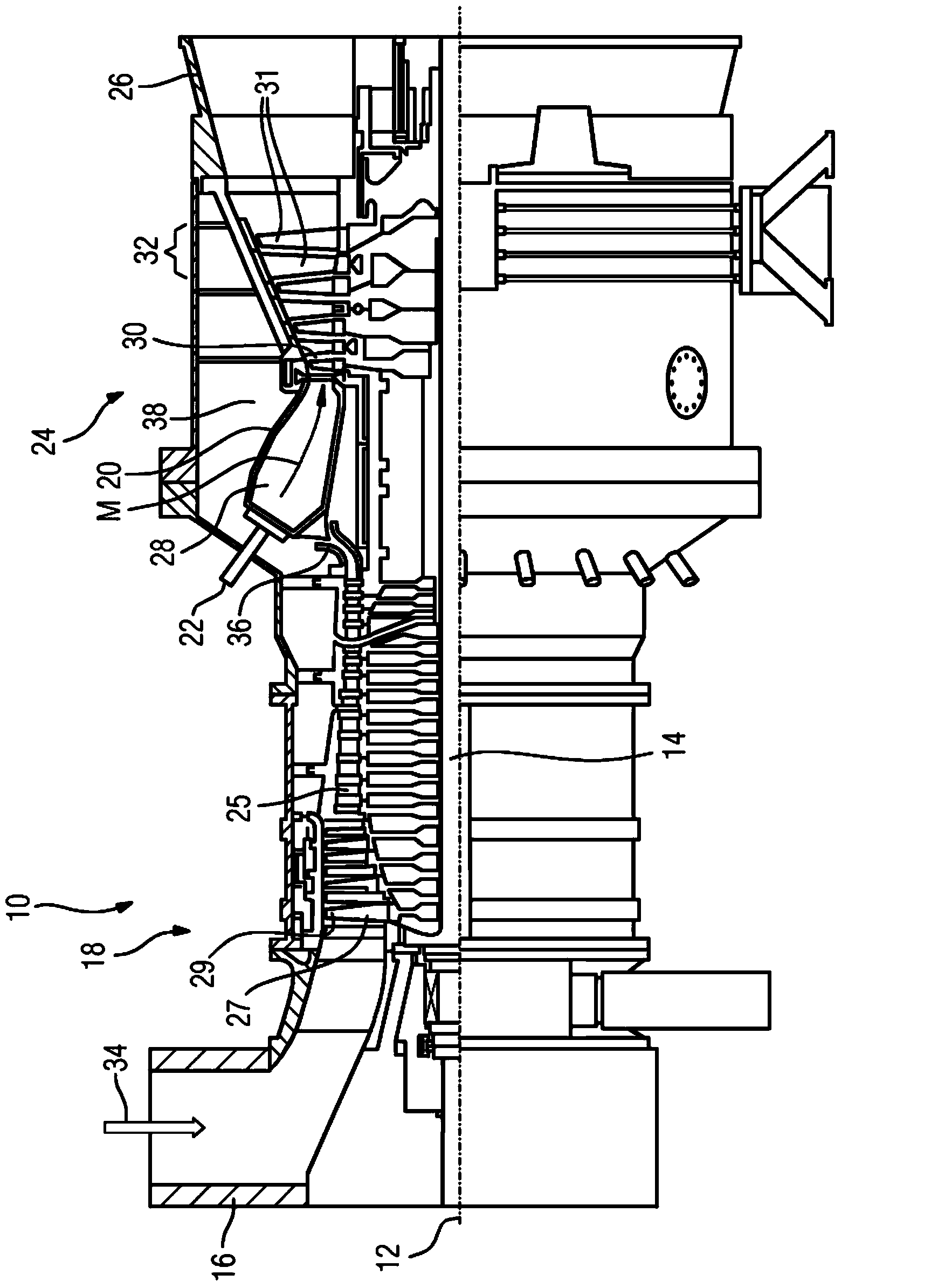

[0017] figure 1 The stationary gas turbine 10 is shown in longitudinal partial section. The gas turbine 10 has internally a rotor 14 mounted in rotation about an axis of rotation 12 , which is also referred to as a turbine rotor. Arranged in succession along the rotor 14 is a suction housing 16 , an axial turbocompressor 18 , a torus-shaped annular combustion chamber 20 with a plurality of burners 22 arranged rotationally symmetrically to one another, a turbine unit 24 and an exhaust housing. 26.

[0018] The axial turbocompressor 18 comprises an annular compressor channel 25 with successive compressor stages consisting of rotor blade rings and guide vane rings cascaded therein. The rotor blades 27 arranged on the rotor 14 lie opposite the outer channel wall with their freely ending airfoil tips 29 . The compressor channel 25 opens into a plenum 38 via a compressor output diffuser 36 . Arranged therein is an annular combustion chamber 20 with its combustion chamber 28 , wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com