Method for calculating fatigue life of flexible thin-wall bearing in harmonic reducer

A technology of harmonic reducer and thin-walled bearing, which can be used in computing, instrumentation, electrical and digital data processing, etc., and can solve the problem of inflexible thin-walled bearing fatigue life calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

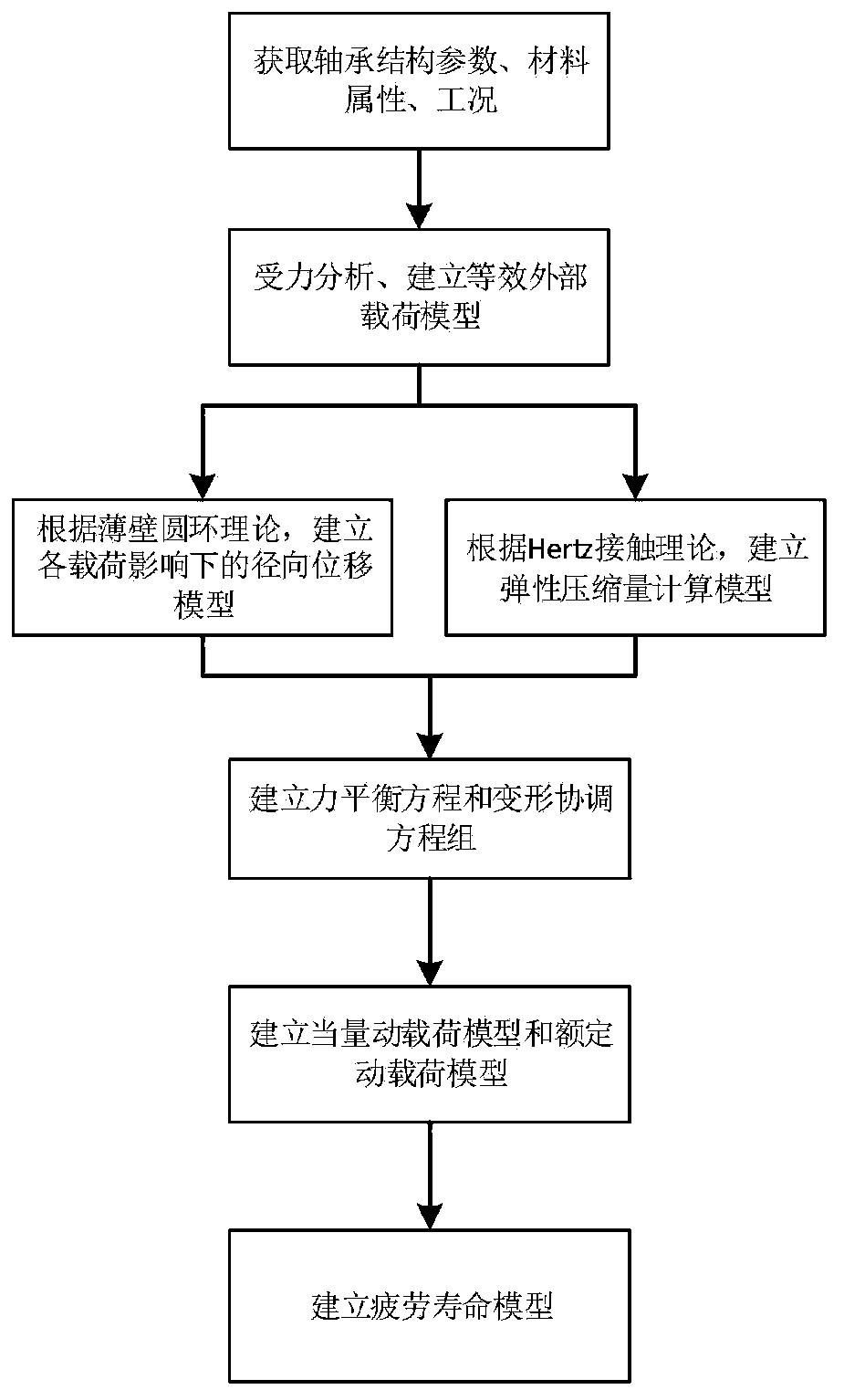

[0025] Calculation method for fatigue life of flexible thin-walled bearings in harmonic reducers, such as figure 1 shown, including:

[0026] 1) Obtain bearing structural parameters, materials, properties, and working conditions;

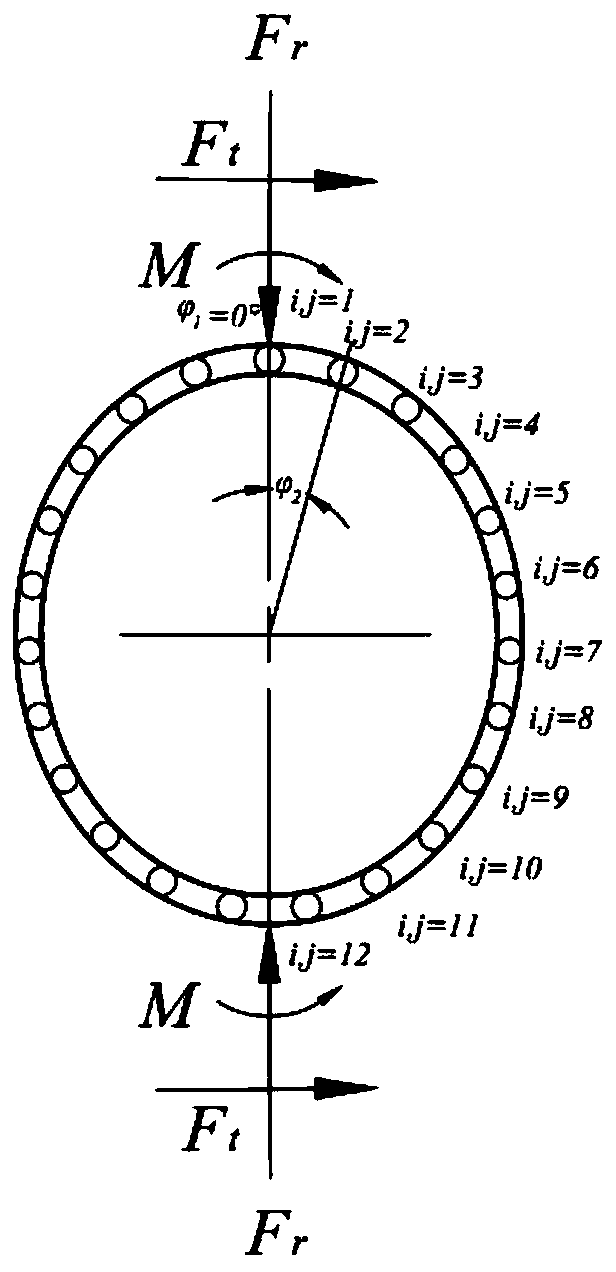

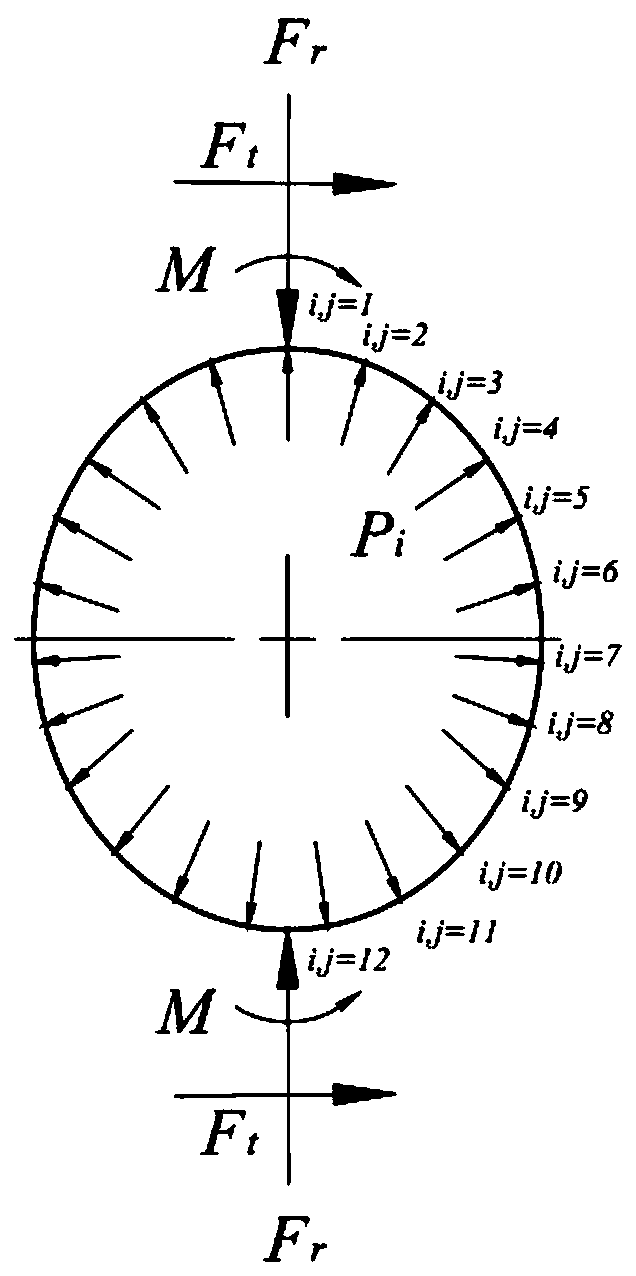

[0027] 2) Stress analysis and establishment of equivalent external load model;

[0028] 3) According to the theory of thin-walled rings, the radial deformation model of the outer ring under the influence of various loads is established; according to the Hertz contact theory, a calculation model for the elastic compression of the contact pair between the ball and the ring is established;

[0029] 4) Establish force balance equations and deformation coordination equations;

[0030] 5) Establish equivalent dynamic load model and rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com