Calibration structure and detection method of bearing internal load distribution

A load distribution and detection method technology, applied in the direction of measuring force, measuring device, force/torque/power measuring instrument, etc., can solve the problems of unsuitable test bearings, etc., and achieve real load distribution inside the bearing, wide applicability, and real-time online The effect of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

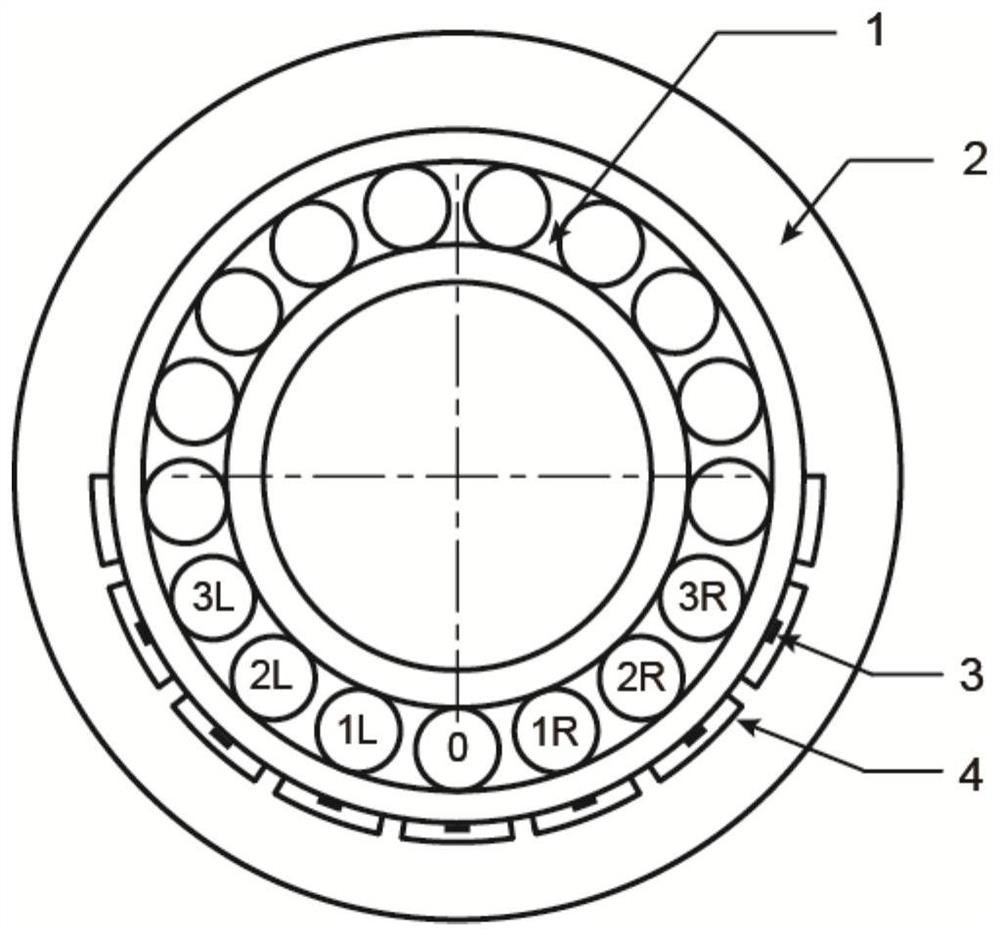

[0033] Such as figure 1 As shown, the present invention provides a bearing internal load distribution detection structure, including a test bearing 1 and a test bearing seat 2 matching the outer ring of the test bearing 1, which is in the test bearing seat 2 corresponding to the bearing area of the test bearing 1 A plurality of grooves 4 are processed on the inner surface, and strain gauges 3 are pasted on the outer surface of the outer ring of the test bearing 1. The number of grooves 4 and strain gauges 3 is the same as the number of rollers in the load-bearing area of the test bearing 1, and the positions are the same as The positions of the rollers in the bearing area of the test bearing 1 correspond to each other, and the strain gauges 3 are connected to a processor (not shown) capable of collecting strain changes.

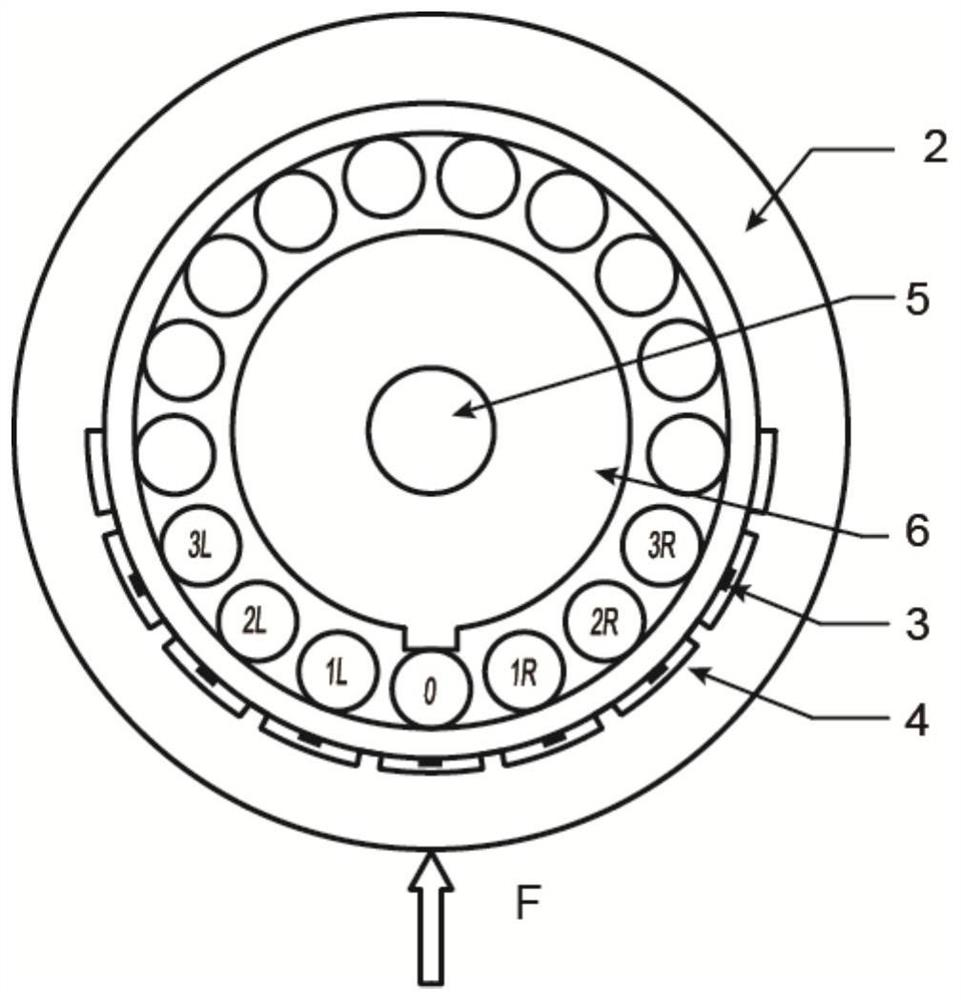

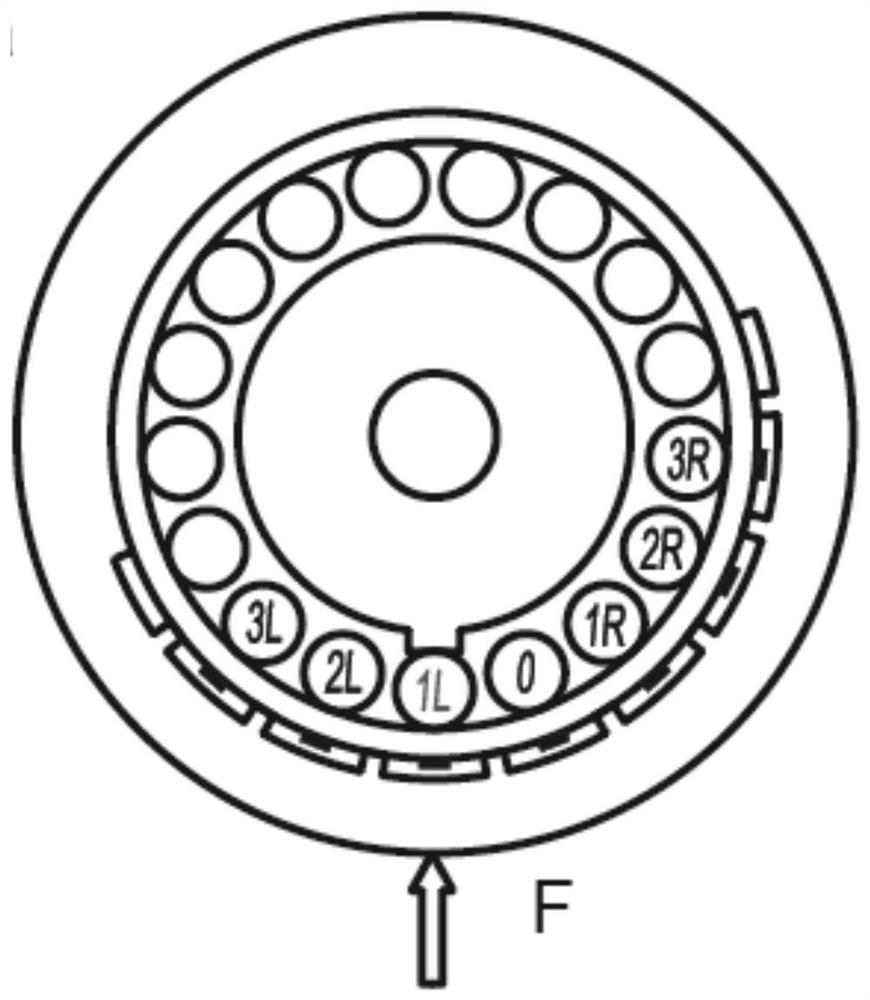

[0034] When using, first perform a calibration experiment, such as figure 2 shown. A calibration sleeve 6 is fitted on the shaft 5, and the inner ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com