Qualitative and quantitative authentication method for selenium in selenium-rich cereals, cereal flour and albumen powder

A technology of grain flour and protein powder, which is applied in qualitative and quantitative identification of selenium in protein powder, grain flour, and selenium-enriched grains. It can solve the problems of not being applicable to organic selenium-rich foods, and achieve strong versatility of equipment and accurate and effective detection results. , high practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

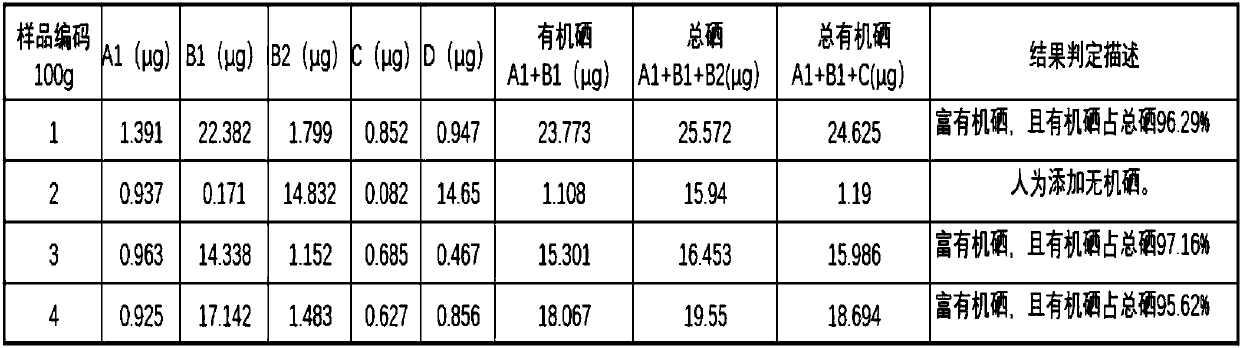

Embodiment 1

[0030] The method for qualitative and quantitative identification of selenium in selenium-enriched grains, grain powders, and protein powders is characterized in that it comprises the following steps:

[0031] (1) Sample pretreatment

[0032] Crush the selenium-enriched grain (the grain powder or protein powder does not need to be crushed), sieve, remove the sample with a size of ≤100 mesh, weigh the specific gram weight with a ten-thousandth analytical balance, and wait for the test;

[0033] (2) washing

[0034] A. Dissolve the sample with deionized water, take 100g of the sample, 600ml of deionized water, heat with an electromagnetic stirrer and fully stir until it becomes a paste liquid;

[0035] B. Then centrifuge, collect the supernatant after centrifugation, then add 400ml deionized water and stir again to dissolve. Centrifuge again, and collect the supernatant again after centrifugation;

[0036] C. Mix the supernatant obtained after the second centrifugation. And ...

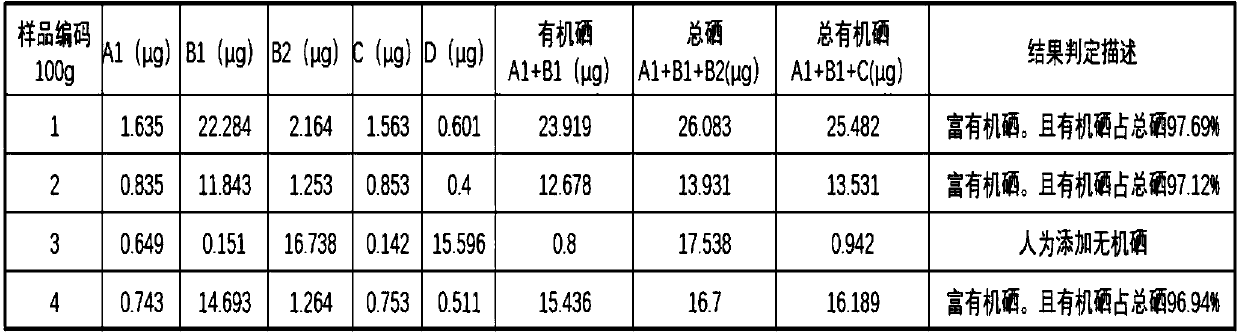

Embodiment 2

[0045] The method for qualitative and quantitative identification of selenium in selenium-enriched grains, grain powders, and protein powders is characterized in that it comprises the following steps:

[0046] (1) Sample pretreatment

[0047] Crush the selenium-enriched grain (the grain powder or protein powder does not need to be crushed), sieve, remove the sample with a size of ≤100 mesh, weigh the specific gram weight with a ten-thousandth analytical balance, and wait for the test;

[0048] (2) washing

[0049] A. Dissolve the sample with deionized water, take 100g of the sample, 600ml of deionized water, heat with an electromagnetic stirrer and fully stir until it becomes a paste liquid;

[0050] B. Then centrifuge, collect the supernatant after centrifugation, add 400ml deionized water to stir and dissolve again after collection, centrifuge again, and collect the supernatant again after centrifugation;

[0051] C. Mix the supernatant obtained after secondary centrifugat...

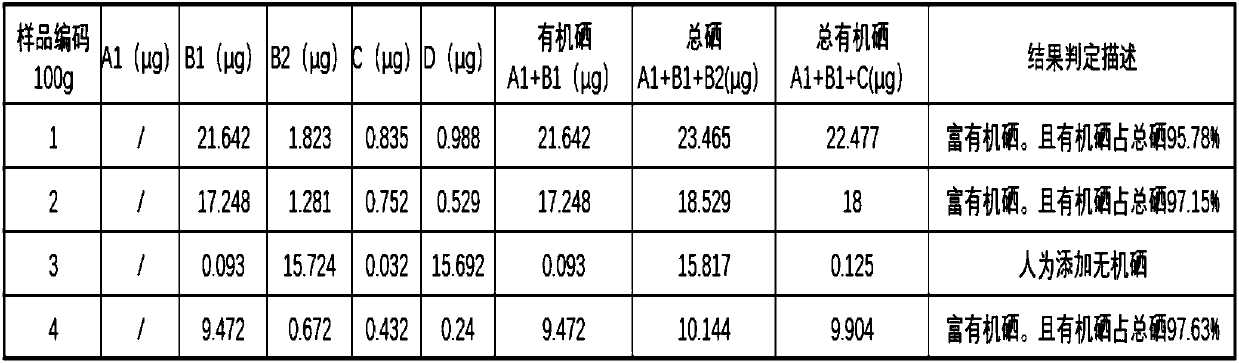

Embodiment 3

[0060] The method for qualitative and quantitative identification of selenium in selenium-enriched grains, grain powders, and protein powders is characterized in that it comprises the following steps:

[0061] (1) Sample pretreatment

[0062] Crush the selenium-enriched grain (the grain powder or protein powder does not need to be crushed), sieve, remove the sample with a size of ≤100 mesh, weigh the specific gram weight with a ten-thousandth analytical balance, and wait for the test;

[0063] (2) washing

[0064] A. Dissolve the sample with deionized water, take 100g of the sample, 600ml of deionized water, heat with an electromagnetic stirrer and fully stir until it becomes a paste liquid;

[0065] B. Then centrifuge, collect the supernatant after centrifugation, add 400ml deionized water to stir and dissolve again after collection, centrifuge again, and collect the supernatant again after centrifugation;

[0066] C. Mix the supernatant obtained after secondary centrifugat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com