Method for adapting a friction coefficient of a separating clutch control device

A technology of separating clutch and friction coefficient, applied in clutch, mechanical equipment, etc., can solve problems such as running interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

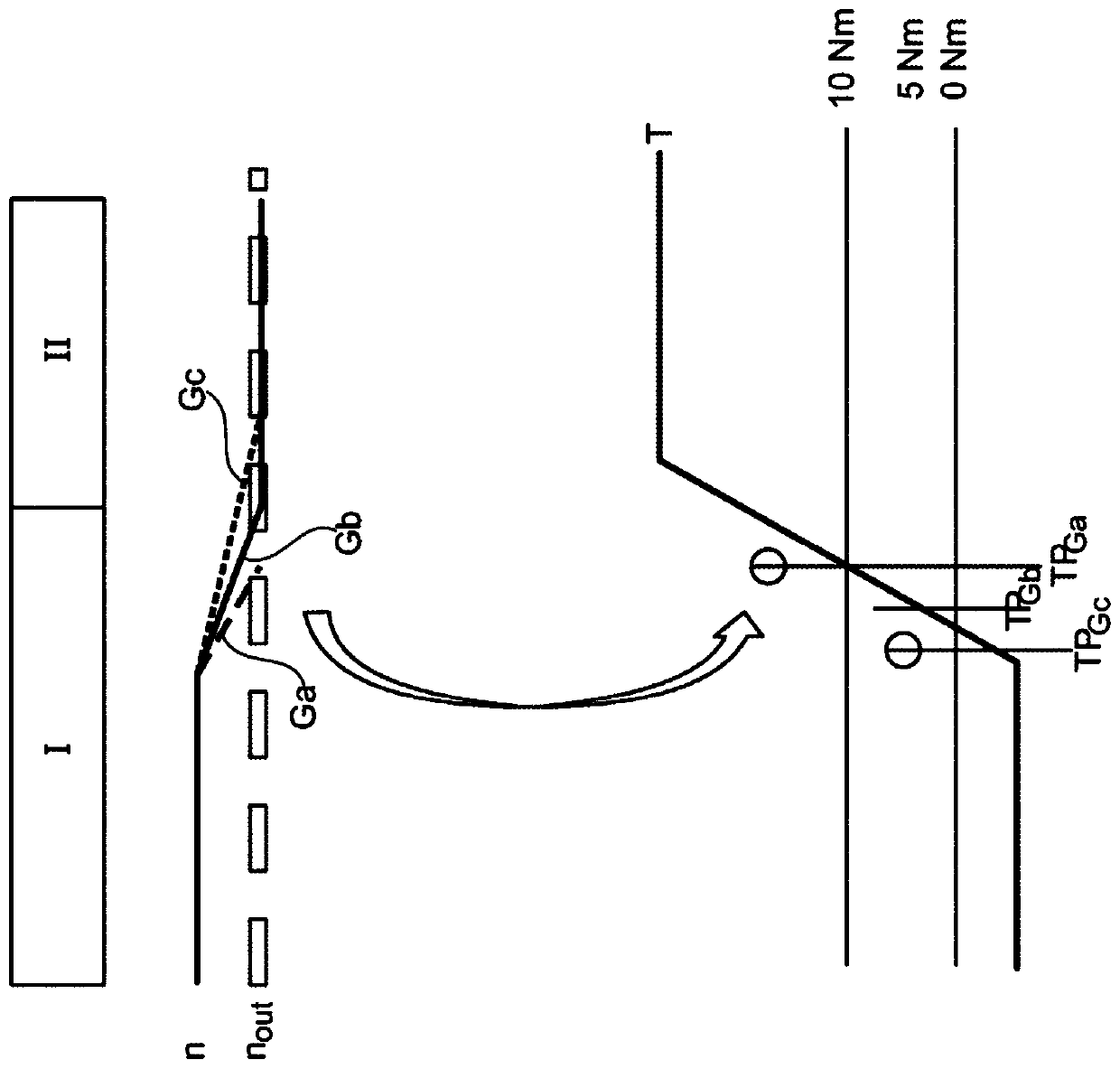

[0027] exist figure 1 A schematic diagram of the powertrain of a hybrid vehicle is shown in . The drive train 1 includes an internal combustion engine 2 and an electric motor 3 . A hybrid separation clutch 4 is arranged between the internal combustion engine 2 and the electric motor 3 directly downstream of the internal combustion engine 2 . The internal combustion engine 2 and the hybrid separation clutch 4 are connected to each other via a crankshaft 5 . The electric motor 3 has a rotatable rotor 6 and a fixed stator 7 . The transmission shaft 8 of the hybrid separation clutch 4 is connected to a transmission 9 which contains a coupling element not shown further, for example a second clutch or a torque converter which is arranged between the electric motor 3 and the transmission between 9. The transmission 9 transmits the torque generated by the internal combustion engine 2 and / or the electric motor 3 to drive wheels 10 of the hybrid vehicle. In this case, the hybrid di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com