Vertical joint connection structure and connection method of assembled integral concrete shear wall structure

A concrete shear wall and connection structure technology, which is applied to walls, building components, building structures, etc., can solve problems such as low construction efficiency, a large number of reinforcements, and a large number of reinforcements, and achieves simple on-site connection, simple production, and high construction efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

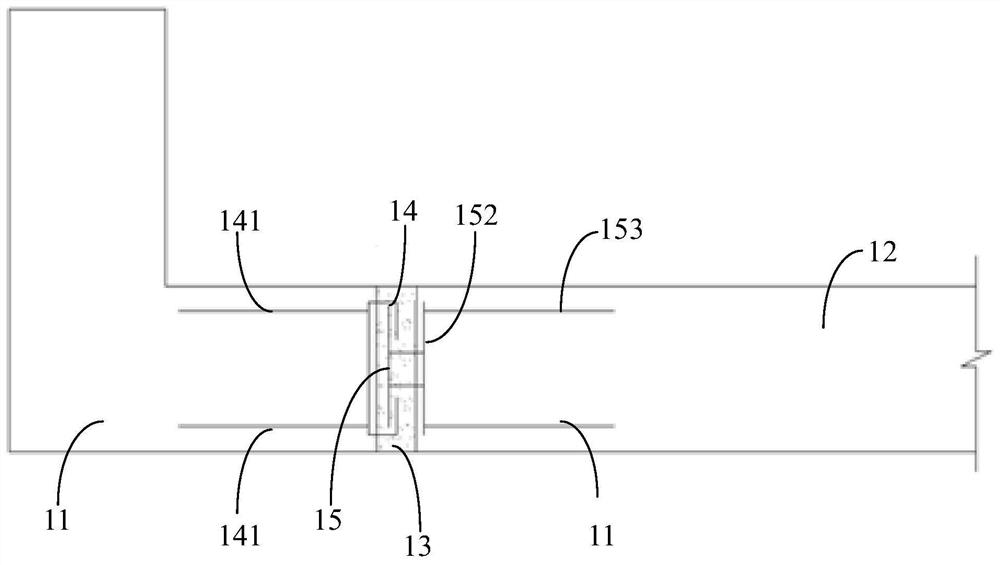

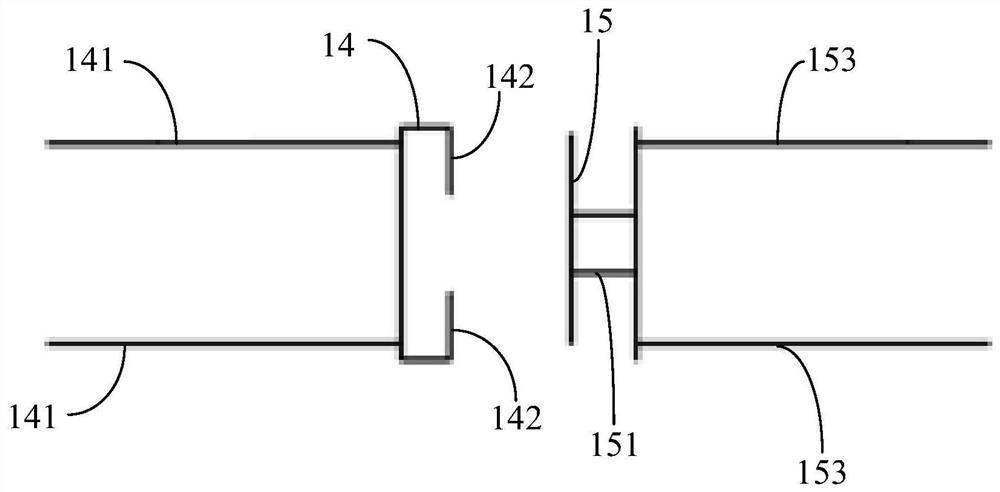

[0038] see figure 1 with figure 2 , figure 1 It shows an exemplary schematic diagram of the vertical joint connection structure of the assembled integral concrete shear wall structure according to the first embodiment of the present invention, figure 2 An exemplary schematic view of the first embedded part and the second embedded part according to the first embodiment is shown.

[0039] The first component 11 is a cast-in-place edge component, and the second component 12 is a prefabricated wall. A post-cast joint 13 with a width of about 50 mm is left before the cast-in-place edge component and the prefabricated wall. The first embedded part 14 and The second embedded part 15 adopts an insertion type node connection. Such as figure 1 with figure 2 As shown, the first embedded part 14 is a U-shaped slot, which is anchored to the surface of the first member 11 to be connected by the first anchor rib 141. The height direction of the U-shaped card slot is set along the le...

Embodiment 2

[0042] see image 3 with Figure 4 , image 3 It shows an exemplary top view schematic diagram of the vertical joint connection structure of the assembled integral concrete shear wall structure according to the second embodiment of the present invention, Figure 4 It shows an exemplary vertical schematic diagram of the vertical joint connection structure of the assembled integral concrete shear wall structure according to the second embodiment of the present invention.

[0043] The first component 11 is a cast-in-place edge component, and the second component 12 is a prefabricated wall. A post-cast joint with a width of about 50 mm is left between the cast-in-place edge component and the prefabricated wall. The first embedded part 14 and the second The two embedded parts 15 are connected by an interlocking node. Such as image 3 with Figure 4 As shown, the first embedded part 14 includes a distance bracket 141 fixed on the side to be connected of the first member 11 and ...

Embodiment 3

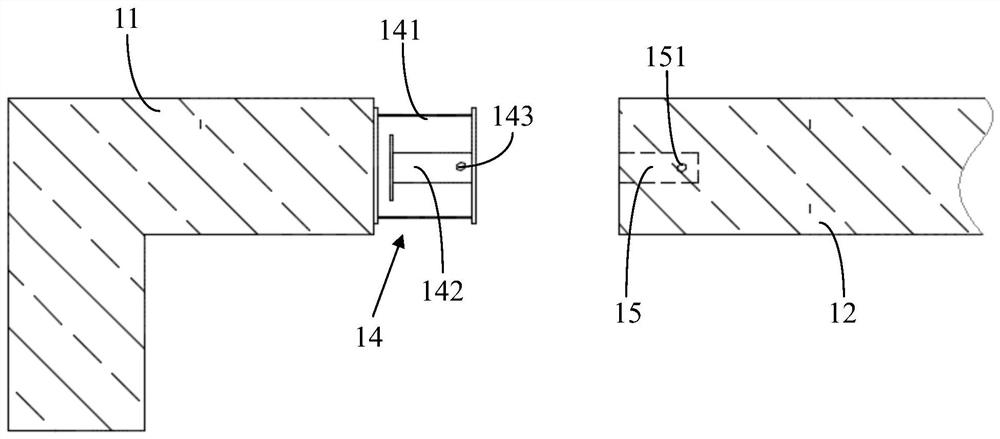

[0045] see Figure 5 , Figure 5 It shows an exemplary perspective view of the vertical joint connection structure of the assembled integral concrete shear wall structure according to the third embodiment of the present invention.

[0046] The first component 11 is a cast-in-place edge component, and the second component 12 is a prefabricated wall. A post-cast joint with a width of about 50 mm is left between the cast-in-place edge component and the prefabricated wall. The first embedded part 14 and the second The two embedded parts 15 are connected by an interlocking node. Such as Figure 5 As shown, the first embedded part 14 is a first connecting plate fixed on the side to be connected of the first member 11, and the first connecting plate can be a steel plate, which is arranged along the height direction of the first member on its to-be-connected side. The surface on one side, and the first connecting plate and the surface to be connected of the first member are perpend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com