A method for unloading a convenient beam when passing under a high-speed railway road-bridge transition section

A technology for high-speed railways and transition sections, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as unfavorable high-speed railway pile foundations and no effective construction measures, so as to ensure safe operation and less interference with existing structures , reduce the effect of eccentric load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

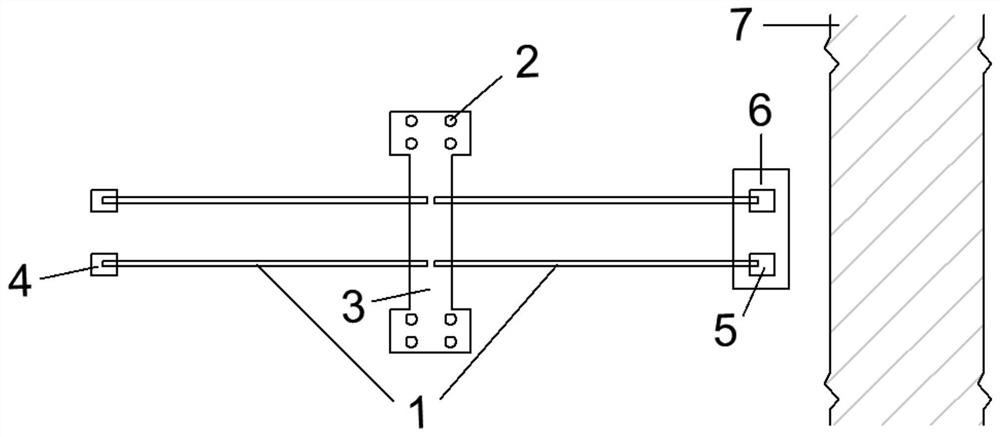

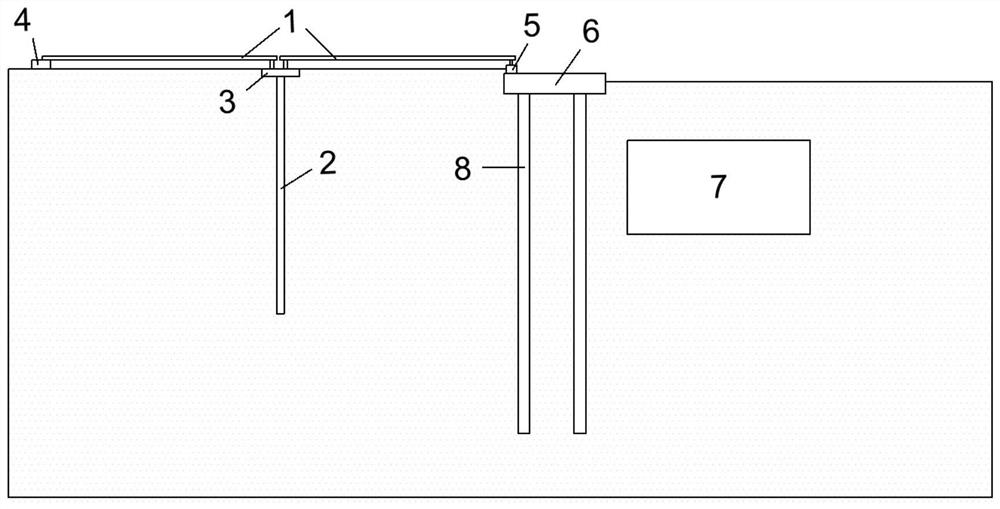

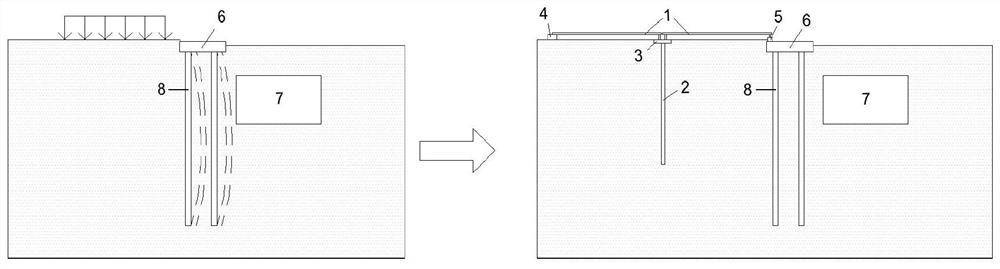

[0040] A frame bridge on the right side of a road passes under a high-speed railway bridge. The outer edge of the side wall of the box body on the south side is 13.43m away from the abutment end of the high-speed railway bridge. The box body is 40.19m long, 15.1m wide and 7.7m high. The thickness of the top plate is 0.9m, the thickness of the bottom plate is 1m, the side wall is 1.05m, and there are 3m conjoined U grooves on both sides of the box body. In order to control the horizontal deformation of the abutment during the construction process of the underpass of the road frame bridge, improve the longitudinal stability of the line, and ensure the safe operation of the high-speed railway, the technical solution provided by this application is used for processing in the underpass section. figure 1 and figure 2 They are the plan and elevation schematic diagrams of the application scenarios of this application, respectively.

[0041] A method for unloading a convenient beam w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com