Buffer method and device for transient excess pore water pressure of railway subgrade

A technology of pore water pressure and buffer device, which is applied in the direction of roads, tracks, ballast layers, etc., can solve the problems of high requirements for grouting materials and difficulty in ensuring long-term strength, so as to prevent grouting and mud discharge and relieve excess pore water The effect of pressure and preventing mud from turning over

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

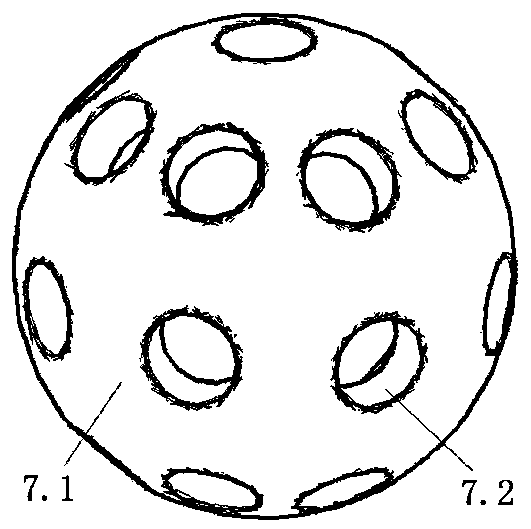

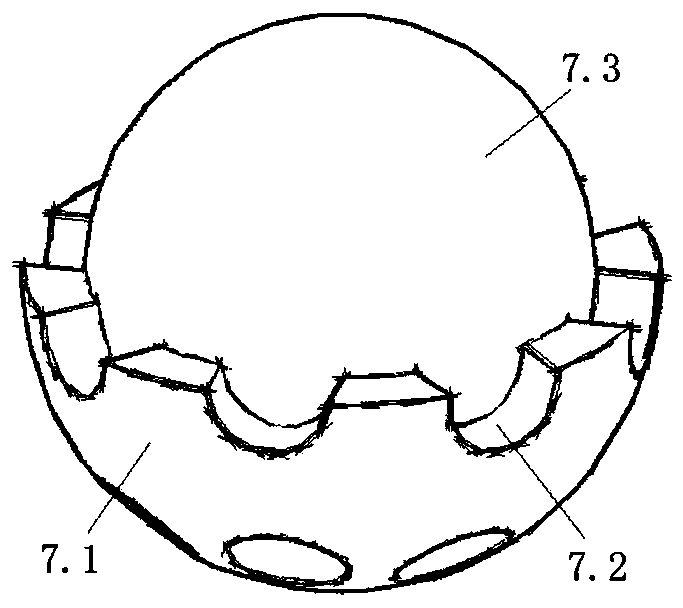

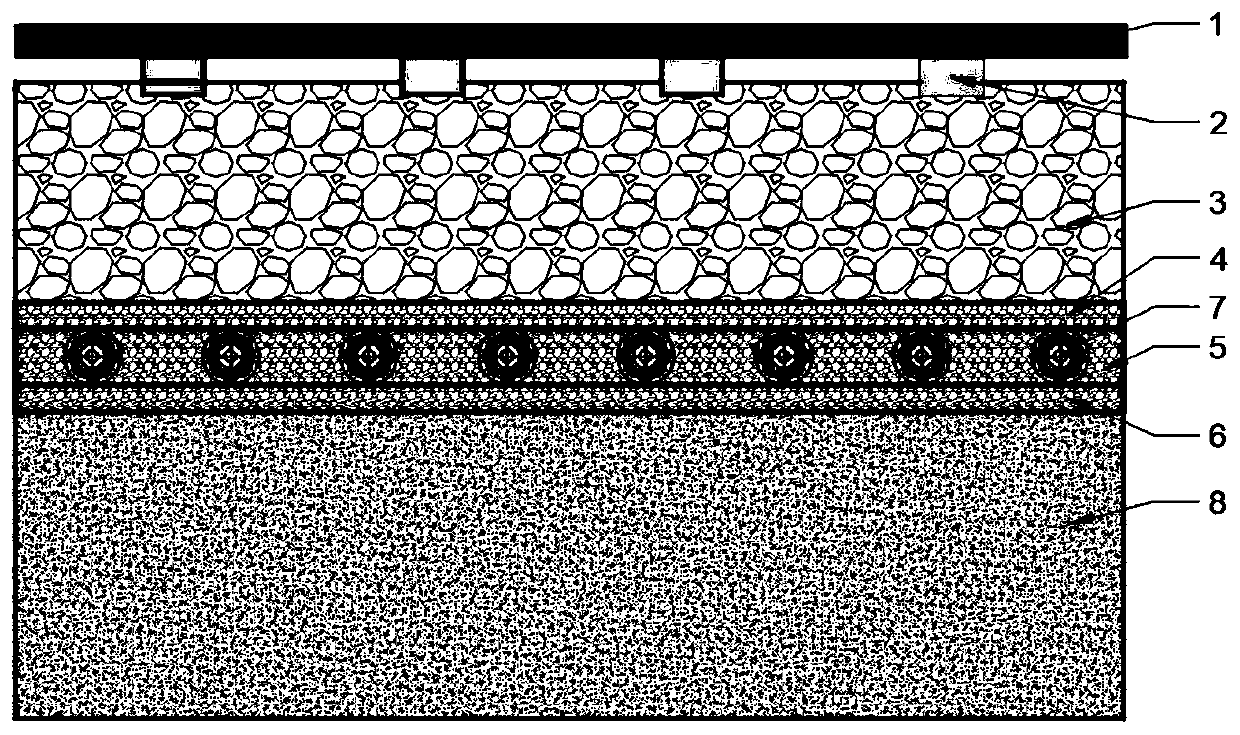

[0036] see Figure 1-2 , a transient pore water pressure buffering device for a railway subgrade, comprising a rigid device for bearing and transmitting the dynamic effective stress of the subgrade and a flexible device for buffering the dynamic pore water pressure of the subgrade, the rigid device is provided with a cavity structure inside And there is at least one water hole connected to the inner cavity on the surface (the cavity structure is the inner cavity), and the pore water flows into or out of the inner cavity through the water hole, and the flexible device is integrally arranged on the rigid The flexible device is elastically deformed by pore water pressure in the inner cavity of the device. That is, when the pore water pressure is greater than the deformation pressure value of the flexible device, the flexible device deforms, and when the pore water pressure is lower than the deformation pressure value of the flexible device, the flexible device returns to its orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com