Novel beer produced by replacing hops with clove and preparation method thereof

A technology of cloves and beer, applied in the direction of beer brewing, etc., can solve problems such as unsatisfactory, achieve high commercial benefits, and enhance the effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

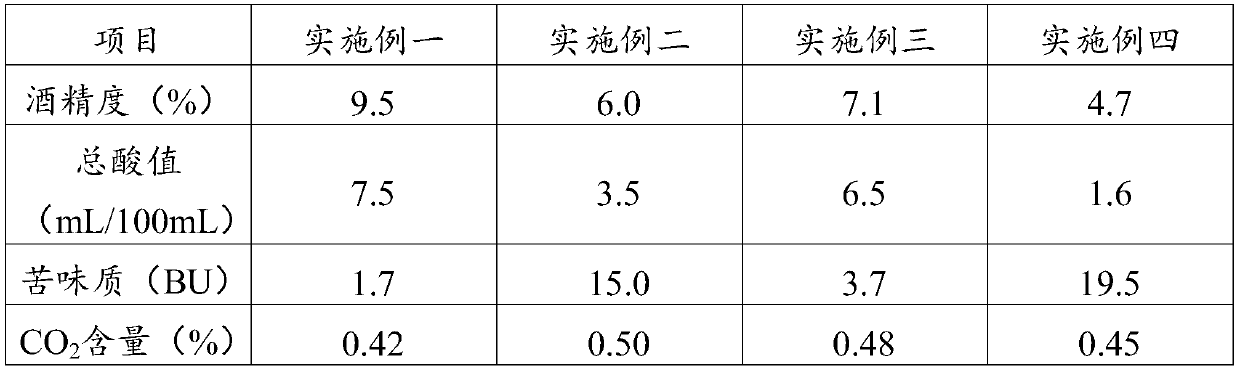

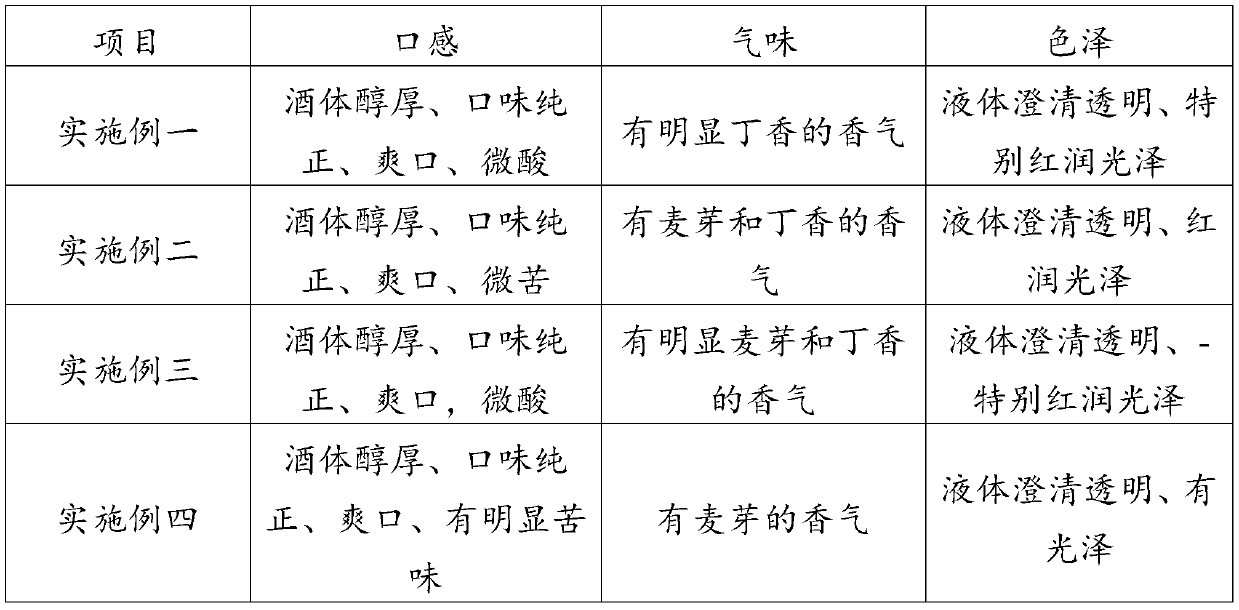

Examples

preparation example Construction

[0030] The present invention provides a kind of preparation method that replaces hops with cloves to produce beer, comprises the following steps:

[0031] Step 1, pretreatment: take raw materials, pulverize;

[0032] Step 2, saccharification: saccharifying the pulverized raw materials to obtain wort;

[0033] Step 3. Boiling: Boil the wort, add cloves in proportion after boiling, and the boiling time is 55-70 minutes;

[0034] Step 4, main fermentation: cooling the boiled wort, filtering to obtain cooled wort, moving the cooled wort to a fermenter, adding yeast for main fermentation, and obtaining tender fermentation liquid;

[0035] Step 5. Post-fermentation: Clarify and filter the tender fermentation liquid to remove the settled yeast, move it to the post-fermentation tank, add white sugar in proportion, and carry out post-fermentation to obtain the new beer primary product.

[0036] Specifically, cloves belong to the family Myrtaceae, and the male cloves after the flower ...

Embodiment 1

[0046] Step 1: Mix the raw materials of oatmeal and wheat according to the weight ratio of 3:2, put them into a mill and grind them;

[0047] Step 2: Control the temperature of the boiled drinking water at 70°C, then add the ground raw materials into it and stir evenly for saccharification treatment for 1 hour to obtain wort. between;

[0048] Step 3: Boil the wort. When boiling for 20 minutes, add cloves at a ratio of 3 grams of cloves per kilogram of raw materials; when boiling for 55 minutes, add cloves at a ratio of 2 grams of cloves per kilogram of raw materials, and boil for a total of one Hour;

[0049] Step 4: Collect the boiled wort, wait for it to cool down to 30°C, put in M21 Belgian wheat yeast to activate for 30 minutes, filter, quickly cool down to about 20°C, move the cooled wort to the fermentation tank, and the wort into the tank The temperature is 22°C, and M21 Belgian wheat yeast is added to the fermenter for main fermentation. The main fermentation temper...

Embodiment 2

[0054] Step 1: Mix the raw materials of oatmeal and wheat according to the weight ratio of 3:2, put them into a mill and grind them;

[0055] Step 2: Control the temperature of the boiled drinking water at 66°C, then add the ground raw materials into it and stir evenly for saccharification treatment for 70 minutes to obtain wort, the saccharification treatment adopts constant temperature fermentation, and the temperature is controlled at 65-70°C between;

[0056] Step 3: Boil the wort. When boiling for 20 minutes, add 4 grams of cloves and 3 grams of traditional hops per kilogram of raw materials, and boil for a total of 70 minutes;

[0057] Step 4: Collect the boiled wort, wait for it to cool down to 28°C, put in M21 Belgian wheat yeast to activate for 40 minutes, filter, quickly cool down to about 20°C, move the cooled wort to the fermentation tank, and the wort into the tank The temperature is 20°C, and M21 Belgian wheat yeast is added to the fermenter for main fermentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com