Back coating type double-station laminating machine and working method thereof

A working method and composite machine technology, applied to printing presses, rotary printing presses, post-processing of printing, etc., can solve problems such as reducing product production efficiency, improve production efficiency and yield, simplify structure, and adapt to subsequent on-line production The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

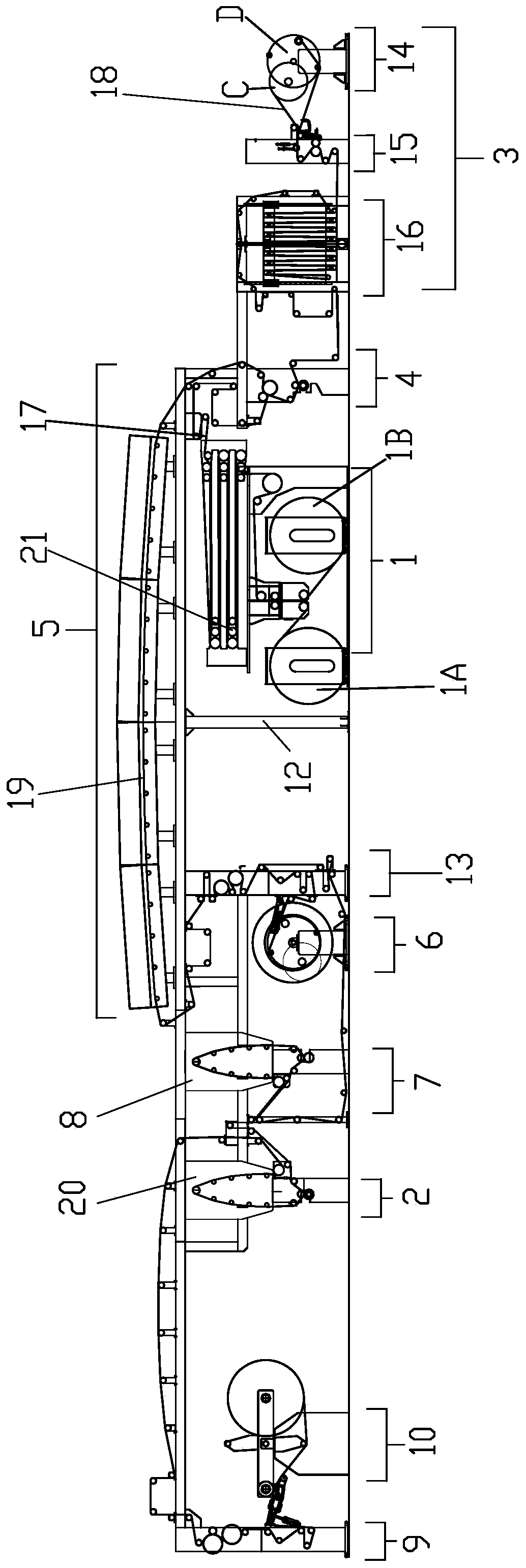

[0027] The technical features of the present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate the understanding of those skilled in the art.

[0028] A kind of double-station composite machine with back coating, such as figure 1 As shown, it includes a paper unwinding unit 1 for outputting paper 17, a film unwinding device 3 for outputting film 18, a coating compound unit 4 for coating and compounding paper 17 and film 18 into composite paper 19, A drying box 5 for drying the composite paper 19, a stripping unit 13 for peeling off the composite paper 19 dried by the drying box 5, a film winding unit 6 for receiving the stripped film 18, The glazing unit 7 for further processing the composite paper 19 peeled off the film 18, the back coating unit 2 for back-coating the glazing composite paper 19, the paper pulling unit 9, and the paper winding unit 10.

[0029] The above paper unwinding unit 1, back coating unit 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com