Process for processing inner surface of cylindrical shell

A technology for the inner surface and processing technology of the shell, which is applied in the direction of metal processing equipment, manufacturing tools, grinding workpiece supports, etc., and can solve the problem that the segmented grinding process cannot be realized, and the ordinary grinding device is difficult to achieve high-precision inner surface grinding, etc. problems, to achieve the effect of ensuring horizontal height, fast positioning and precise positioning, and ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

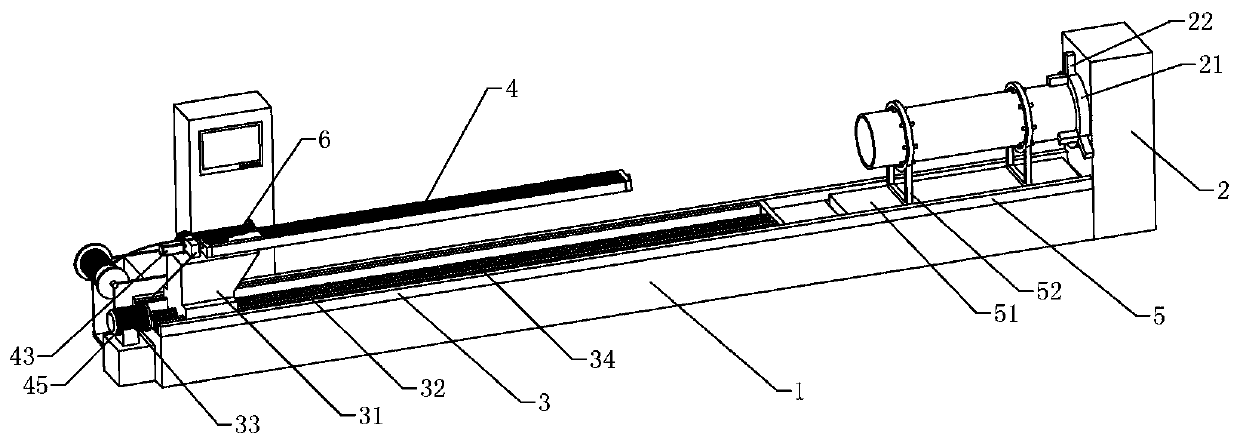

[0029] according to figure 1 , figure 2 As shown, a processing technology for the inner surface of a cylindrical shell, including using a double pallet feeding device, and processing according to specific processing steps through an electronic control system;

[0030] The double pallet feeding equipment includes a processing table 1, a housing rotating mechanism 2, and a first pallet mechanism 3, a second pallet mechanism 4 and a housing supporting mechanism 5 provided on the processing table 1. The housing supporting mechanism 5 includes , lifting table 51 and support frame 52; the first pallet mechanism 3 comprises, sliding pallet 31, guide rail 32, first servo motor 33 and first positioning screw 34, and guide rail 32 is installed on the top of processing table 1, the first The positioning screw 34 is arranged between the guide rails 32, the sliding pallet 31 is slidably connected with the processing table 1 through the first positioning screw 34 and the guide rail 32, an...

Embodiment 2

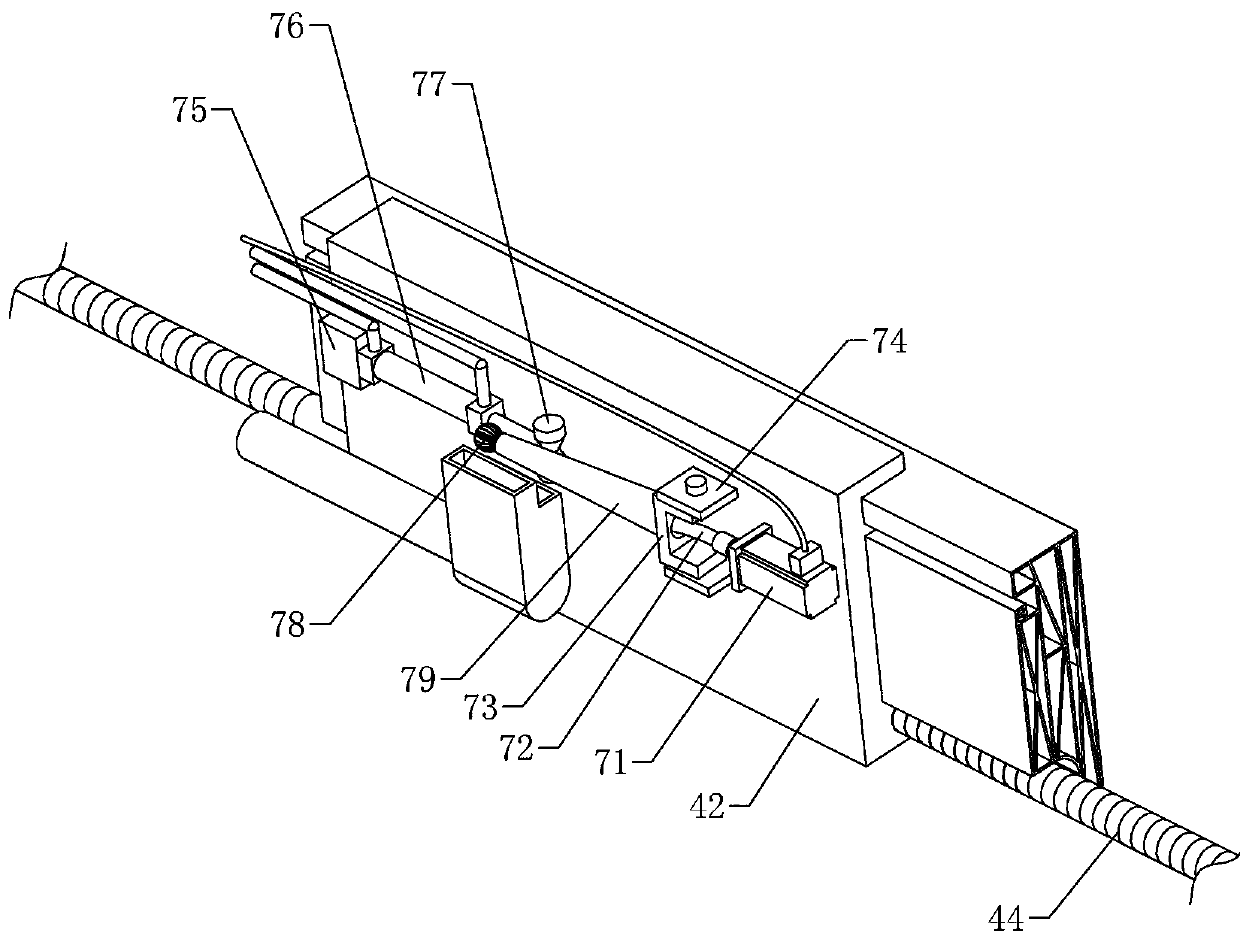

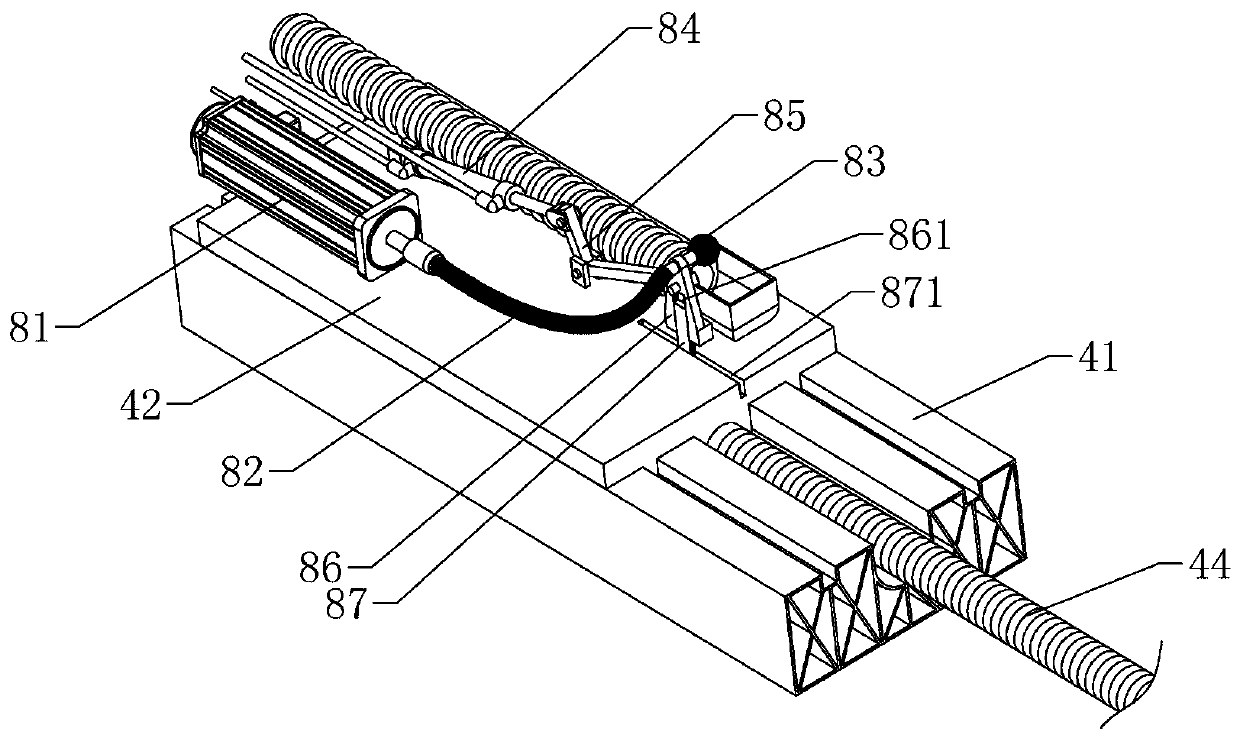

[0040] according to figure 1 , image 3 As shown, a processing technology for the inner surface of a cylindrical shell, including using a double pallet feeding device, and processing according to specific processing steps through an electronic control system;

[0041] The double pallet feeding equipment includes a processing table 1, a housing rotating mechanism 2, and a first pallet mechanism 3, a second pallet mechanism 4 and a housing supporting mechanism 5 provided on the processing table 1. The housing supporting mechanism 5 includes , lifting table 51 and support frame 52; the first pallet mechanism 3 comprises, sliding pallet 31, guide rail 32, first servo motor 33 and first positioning screw 34, and guide rail 32 is installed on the top of processing table 1, the first The positioning screw 34 is arranged between the guide rails 32, the sliding pallet 31 is slidably connected with the processing table 1 through the first positioning screw 34 and the guide rail 32, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com