Preparation method of oxygen evolution catalyst for transition metal group metal sulfide

A metal sulfide and transition metal technology, applied in the field of oxygen evolution catalysts, can solve the problems of cumbersome steps and unfavorable green production, and achieve the effect of simple method, low raw material cost and good catalytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

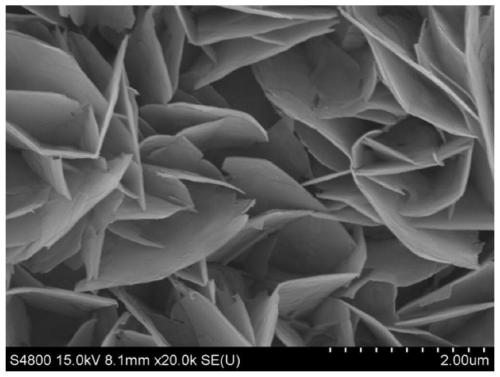

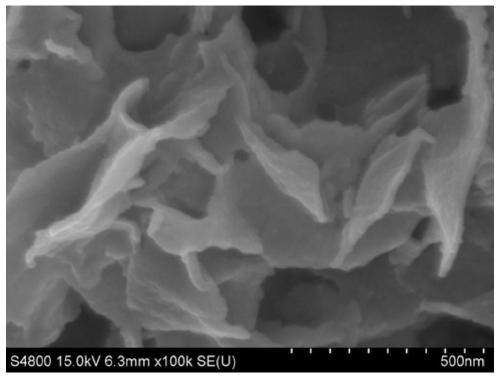

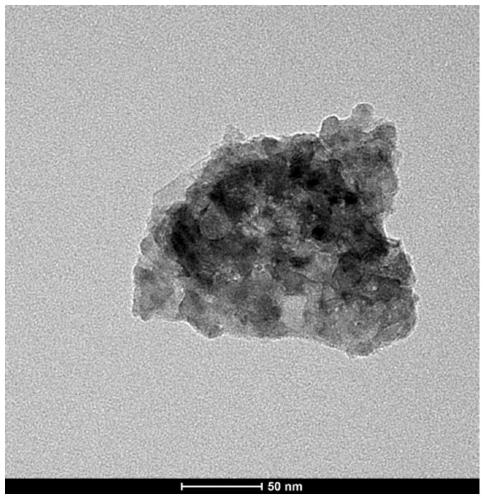

[0030] Step 1, the configuration concentration is 29mmol / L nickel nitrate aqueous solution, add ammonium fluoride and urea, make the final concentration of ammonium fluoride and urea respectively 0.17mol / L and 0.34mol / L, transfer the mixed solution to 100ml in the reactor;

[0031] Step 2, immersing the washed nickel foam into the above mixed solution, and performing a hydrothermal reaction at 120° C. for 12 hours to obtain a nickel hydroxide nanosheet array;

[0032] Step 3: Rinse the nickel foam on which the nickel hydroxide nanosheet array is grown with deionized water, and then soak it in a potassium ferricyanide solution with a concentration of 22 mmol / L for 12 hours, and control the temperature to be 60°C;

[0033] Step 4, transfer the soaked sample to Na with a concentration of 0.2 mol / L 2 In S, the reaction was carried out at 100° C. for 10 hours. After the reaction, the reaction was washed with water and dried in vacuum to obtain an iron-doped nickel sulfide oxygen e...

Embodiment 2

[0038] This example is basically the same as Example 1, the only difference is that the time for soaking potassium ferricyanide is changed to 18 hours, and other conditions remain unchanged.

Embodiment 3

[0040] This example is basically the same as Example 1, the only difference is that the time for soaking potassium ferricyanide is changed to 6 hours, and other conditions remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com