Novel back contact heterojunction battery and manufacturing method thereof

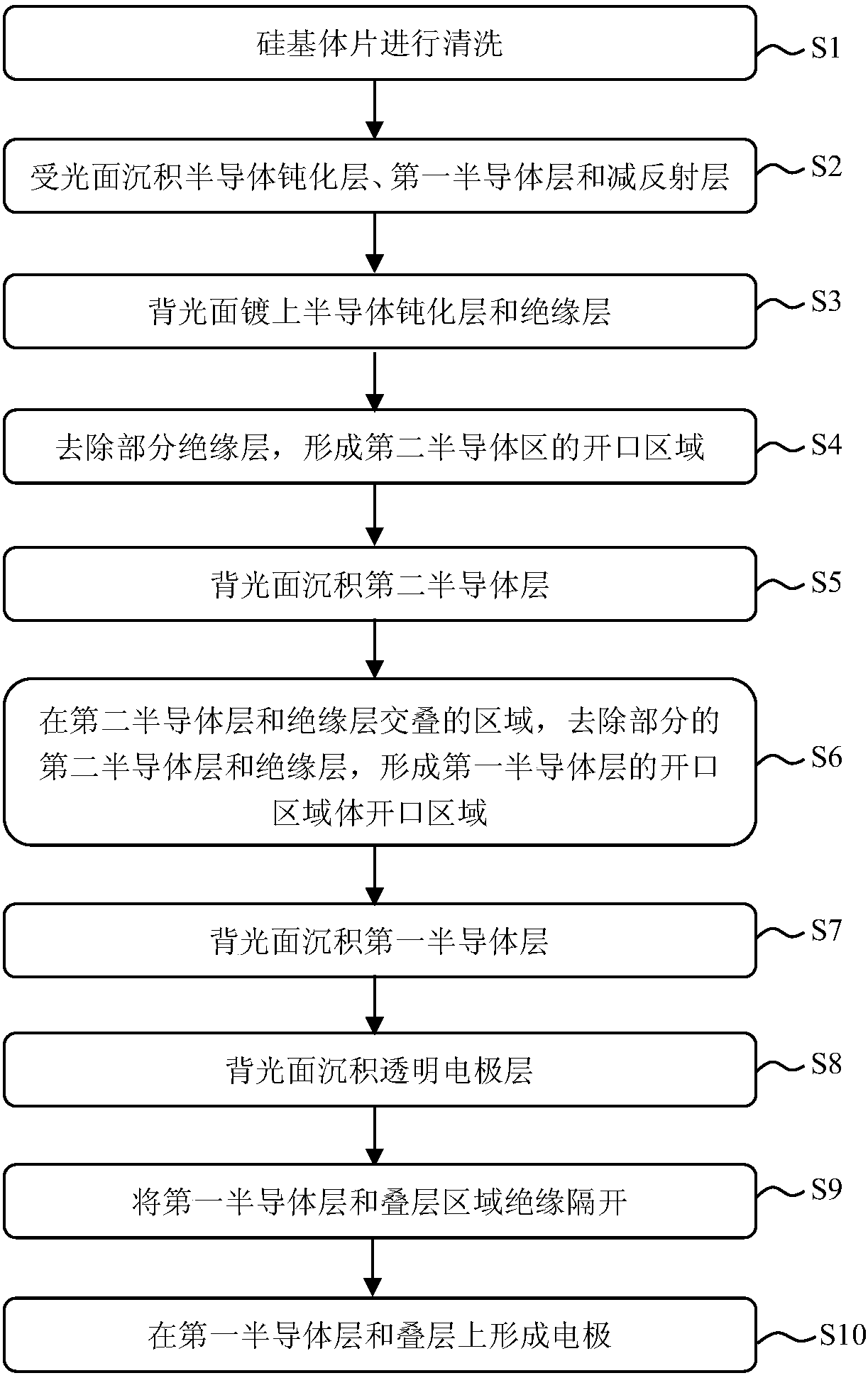

A technology of heterojunction cells and manufacturing methods, which is applied in the field of solar cells, can solve the problems of inapplicability to large-scale mass production, complicated and lengthy process flow, and low production capacity per unit time, so as to reduce performance damage and the complexity of alignment, The effect of simple operation steps and shortened production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Such as figure 1 As shown, a new type of back-contact heterojunction cell includes a silicon base sheet 1, the light-receiving surface of the silicon base sheet 1 is sequentially provided with a semiconductor passivation layer 2i, a first semiconductor layer 2n and an anti-reflection layer 3, the The backlight surface of the silicon substrate sheet 1 is provided with a semiconductor passivation layer 4i, and on the semiconductor passivation layer 4i, first semiconductor layers 4n, second semiconductor layers 4p and stacked layers 4np of the first semiconductor layers 4n are alternately arranged. The layer 4n and the laminated layer 4np are respectively provided with a transparent conductive film layer 6, and the transparent conductive film layer 6 is provided with an electrode 7, and an insulating isolation layer is provided between the first semiconductor layer 4n and the laminated layer 4np, and the second An interband tunneling contact is formed between the semicondu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com