Arc isolation cover of circuit breaker

A circuit breaker and circuit breaker body technology, applied in the direction of circuit breaker components, etc., can solve the problems of phase-to-phase breakdown, lower insulation degree, and the influence of circuit breaker insulation protection level on the difficulty of installation, so as to prevent welding and reduce manufacturing costs. Low, to avoid the effect of phase breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

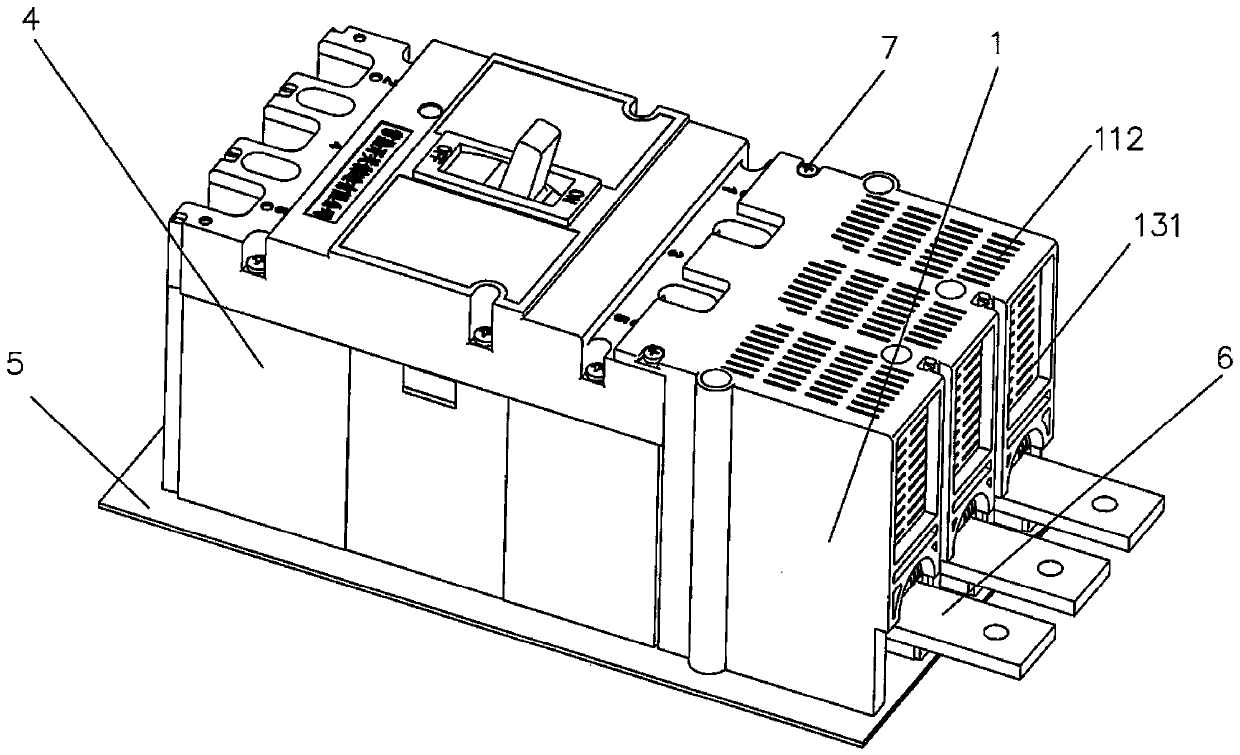

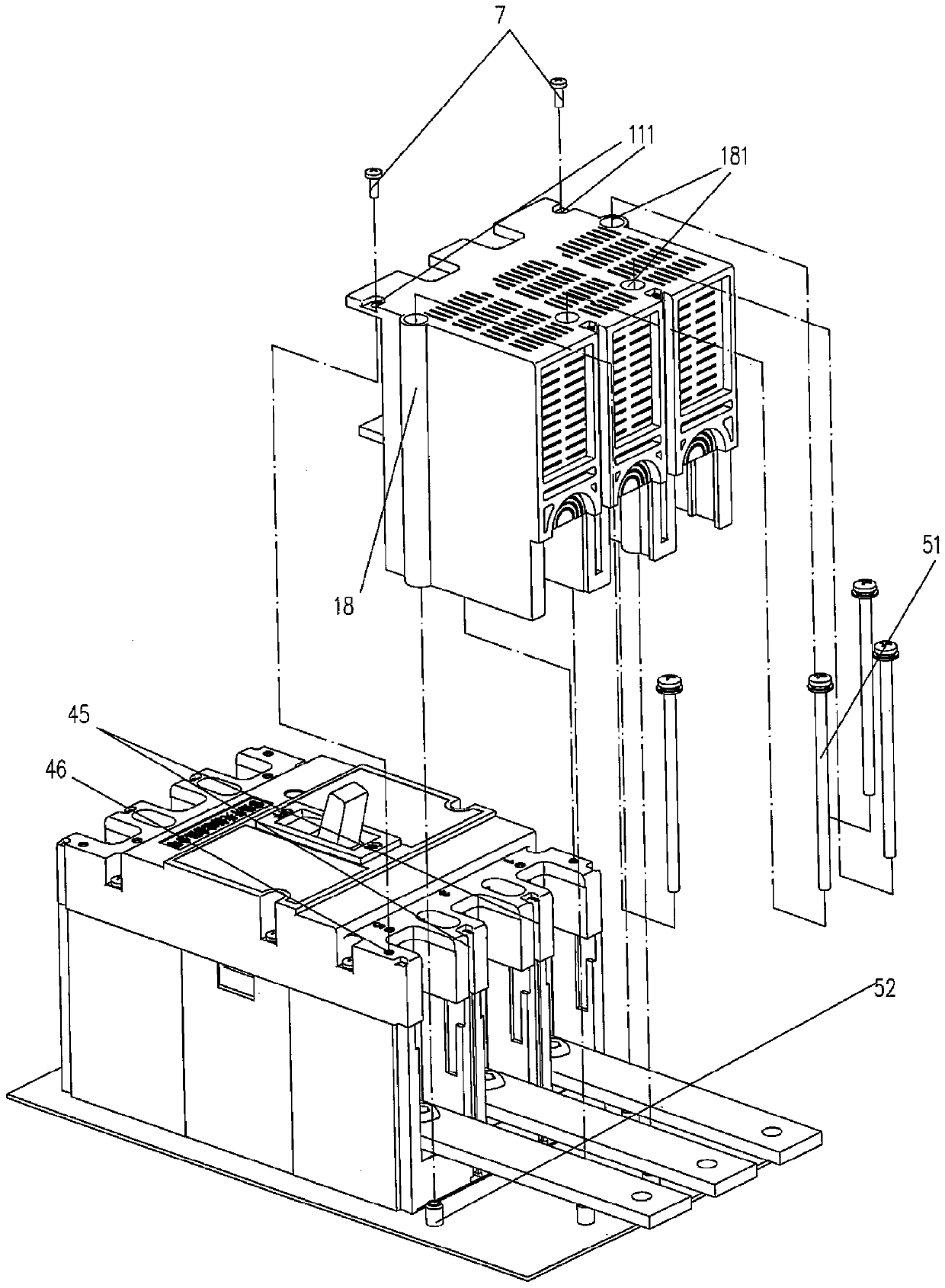

[0070] Such as Figure 1a , 1b , 1c, 4, 5a, 5b, the circuit breaker body 4 and the outer arc shield 1 are fixed on the bottom plate 5 in a state distributed from left to right, and the outer arc shield 1 includes Two side panels 12 facing each other in parallel, a top plate 11 between the upper parts of the pair of side panels 12 and a rear panel 13 away from the circuit breaker body 4, so that the outer arc shield 1 is in the shape of a parallelepiped and forms a direction toward The opening of the circuit breaker body 4 , the circuit breaker body 4 and the outer arc shield 1 are fixed on the bottom plate 5 and the opening of the outer arc shield 1 is engaged with the circuit breaker body 4 . In the outer arc shield cavity of the outer arc shield 1 and between the pair of side panels 12, interphase partitions 14 are arranged at intervals, and the phase partitions 14 are parallel to the pair of side panels 12. And the height of the phase partition 14 is adapted to the pair of...

Embodiment 2

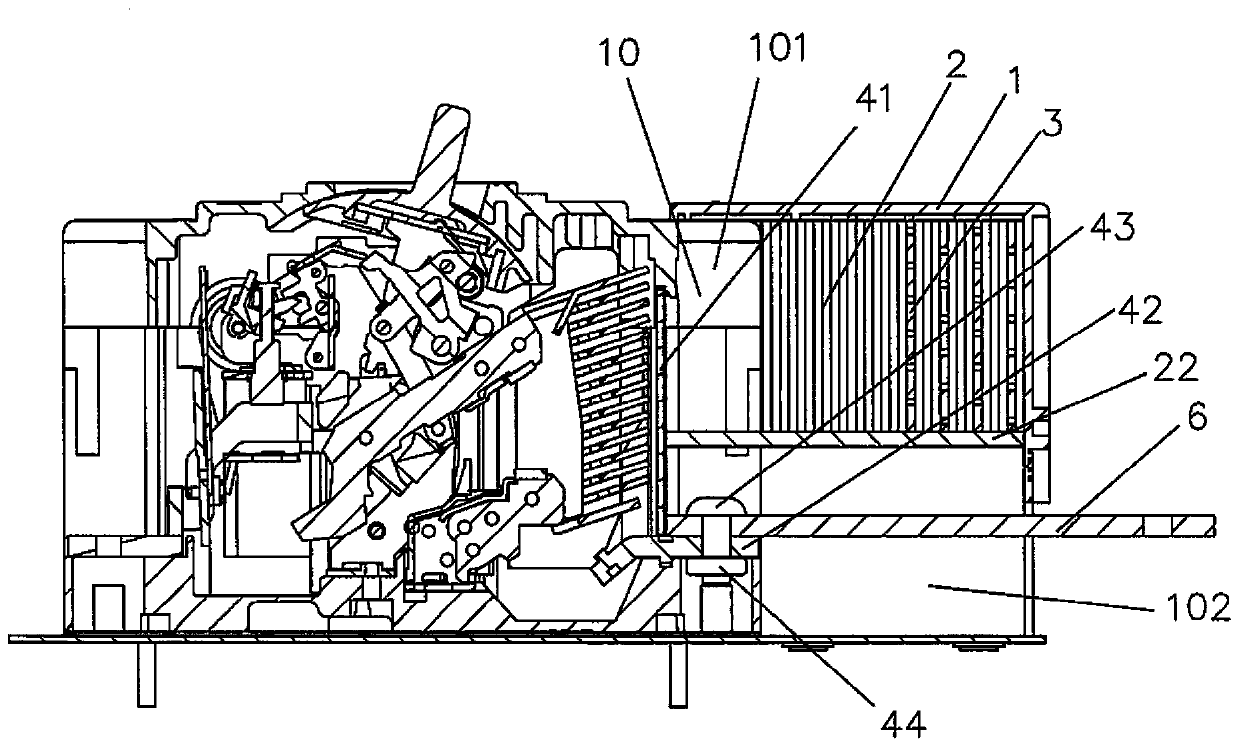

[0076] Such as Figure 6a , 6b As shown, the inner arc shield 2 described in this embodiment is inserted into each chamber 10 of the outer arc shield 1 as a single part, so its number is equal to the number of phases of the circuit breaker body 4 . The inner arc shield 2 is installed on the lower part of the outer arc shield 1, and the cross section of the inner arc shield 2 is "Π" shape, that is, the isolation insulating plate 22 is located on the top of the two side plates 21 and parallel Therefore, the upper chamber of the isolation insulating board 22 is the deionization chamber 101 , and the lower chamber is the wiring bar installation chamber 102 . The top plate 11 of the outer arc shield 1 protrudes toward the insulating insulating plate 22 with an outer arc shield reinforcing rib 113, and the outer arc shield reinforcing rib 113 extends to the inner wall of the side panel 12 or is spaced apart from each other. On the plate 14 , the strip-shaped ribs extending to the ...

Embodiment 3

[0079] Such as Figure 7a , Figure 7b As shown, the inner arc shield 2 described in this embodiment is integrally arranged and spliced with the outer arc shield 1 as a whole part to form an arc shield, and the inner arc shield 2 is installed on the outer arc shield 1 the lower part. The interphase partitions 14 extend from the top plate 11 in the outer arc shield cavity of the outer arc shield 1 to an extent suitable for the height of the free space elimination chamber 101 .

[0080] The inner arc shield 2 includes two side plates 21 arranged facing each other and parallel to each other, and a partition plate 24 arranged between the two side plates 21 and adapted to the height of the terminal block installation cavity 102. Both ends of the insulating spacer 22 are connected to opposite sides of a pair of side plates 21 , and the middle of the insulating spacer 22 is connected to the top of the spacer 24 . The partitions 24 are provided with cylindrical installation ribs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com