Superconducting cable

A technology of superconducting cables and superconducting wires, which is applied in the direction of superconducting devices, superconducting/high-conducting conductors, and the usage of superconducting elements. It can solve the problems of large bending radius of superconducting cables and cannot meet work requirements. Achieve the effect of reducing the bending radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

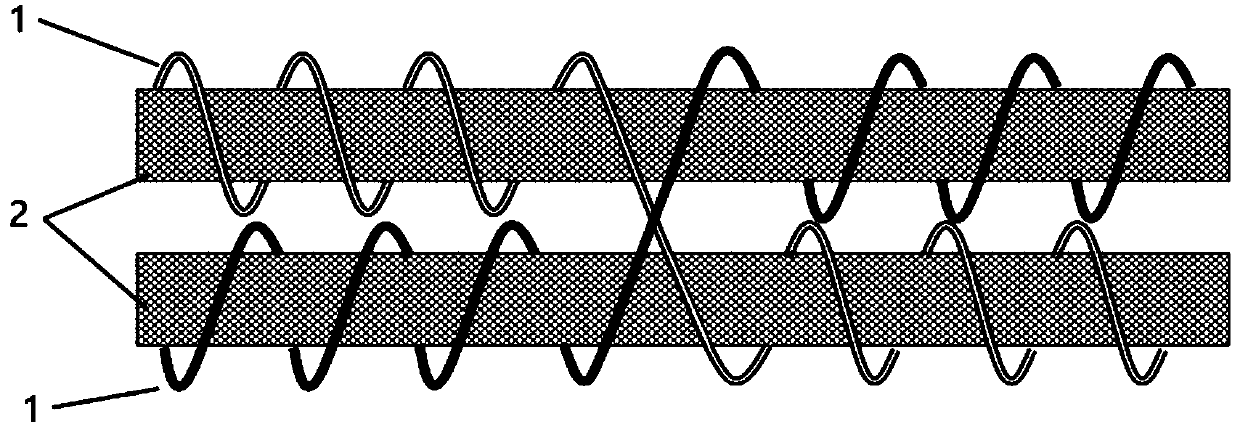

[0031] like figure 1 and Image 6 As shown, the superconducting cable provided by the embodiment of the present invention includes a superconducting wire 1 and a cable core 2. The superconducting wire 1 is helically wound on the cable core 2 along the length direction of the cable core 2. The cable core 2 is solid and Can be bent and deformed.

[0032] In the superconducting cable of the present invention, one or more superconducting wires are wound on one or more cable cores, and each superconducting wire is helically wound on the cable core along the extending direction of the cable core. Since the cable core can be bent and deformed, the guide wire can realize the overall deformability of the cable, and the bending radius of the cable core is greatly reduced compared with the hollow tubular cable core of the prior art when the cable core is solid, which is conducive to adapting to various practical situations. The bending deformation application requirements of the enviro...

Embodiment 2

[0040] like figure 2 As shown, the superconducting cable of this embodiment is basically the same as the first embodiment above, except that the superconducting wire 1 is a YBCO high-temperature superconducting wire coated with a polyimide rubber insulating layer 4, and the cable core 2 is a The polyimide glue insulation layer 4 is covered, and the cable core 2 is formed by twisting the carbon fiber core 3 . The first superconducting wire is first wound with a pitch of 8mm on the first cable core with a diameter of 8mm for 2 turns, then wound in the same form on the second cable core of the same specification, and then returns to the first cable The cable core is wound in this cycle. The second superconducting wire is first wound on the second cable core for 2 turns with a pitch of 8mm, and then wound in the same form on the first cable core of the same specification, and then Return to the second core and wind in this loop.

Embodiment 3

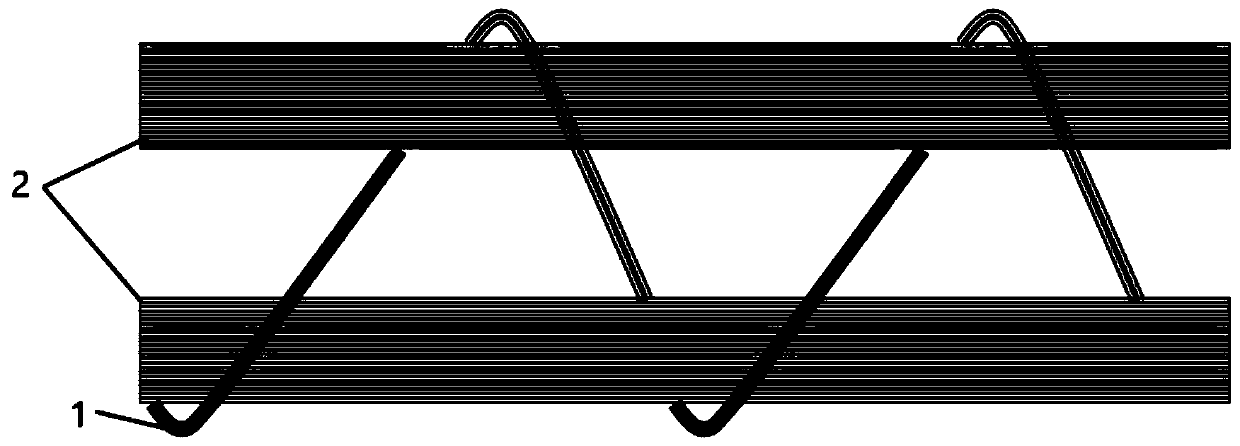

[0042] like image 3 As shown, the superconducting cable of this embodiment is basically the same as the first embodiment above, the difference is that the superconducting wire 1 is one, and the superconducting wire 1 is opposite to the cable core 2 in the form of forward rotation or anti-rotation single turn alternately. Winding root by root. The superconducting wire is wound on the first cable core with a clockwise forward rotation for 1 turn, and then on the second cable core with a counterclockwise anti-rotation for 1 turn, and then returns to the first cable core, and is wound in this cycle. The surface of the superconducting wire contacting the cable core in the cable is replaced to further reduce the AC loss.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com