Ultrasonic detection device for oil pipeline defect

A technology for ultrasonic detection and oil pipelines, which is applied to measuring devices, pipeline systems, and analysis of solids using sound waves/ultrasonic waves/infrasonic waves, etc. problem, achieve the effect of reducing the risk of jamming, simple structure and good diameter changing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

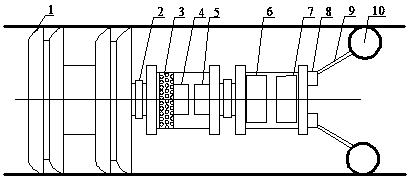

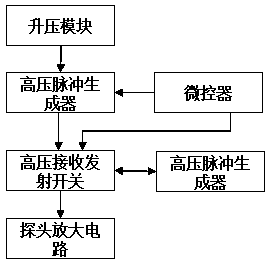

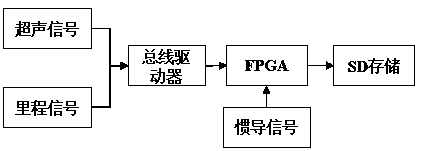

[0022] Such as figure 1 As shown, an ultrasonic detection device for oil pipeline defects includes: a pigging section, a defect detection section, and a power supply section. Universal joints (2) are used for connection between the pigging section and the defect detection section, and between the defect detection section and the power supply section. The pigging section is mainly composed of two pairs of petal-type cups (1) interlaced and stacked, and supported by interval cups. The cups are driven by the pressure difference, so that the ultrasonic detection device for oil pipeline defects is advanced in the direction of oil transmission. The defect detection section (2) includes three rows of multiple ultrasonic sensors (3) uniformly distributed along the circumferential direction, a probe signal processing system (4) and an inertial navigation system (5), which moni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com