A detector for detecting tiny scratches on the surface of the car shaft

A detector and scratch technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of limited measurement accuracy of camera accuracy, inability to detect scratch depth features, insufficient scratch measurement accuracy, etc., to improve the repeatability of positioning accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

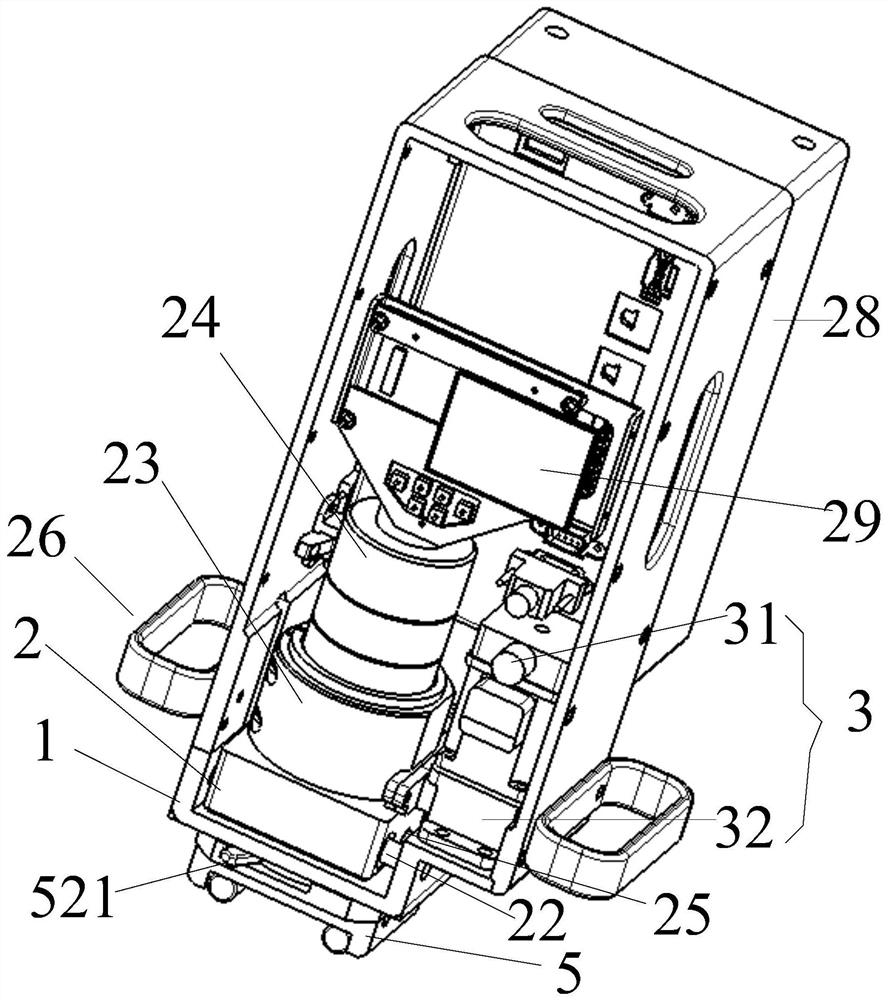

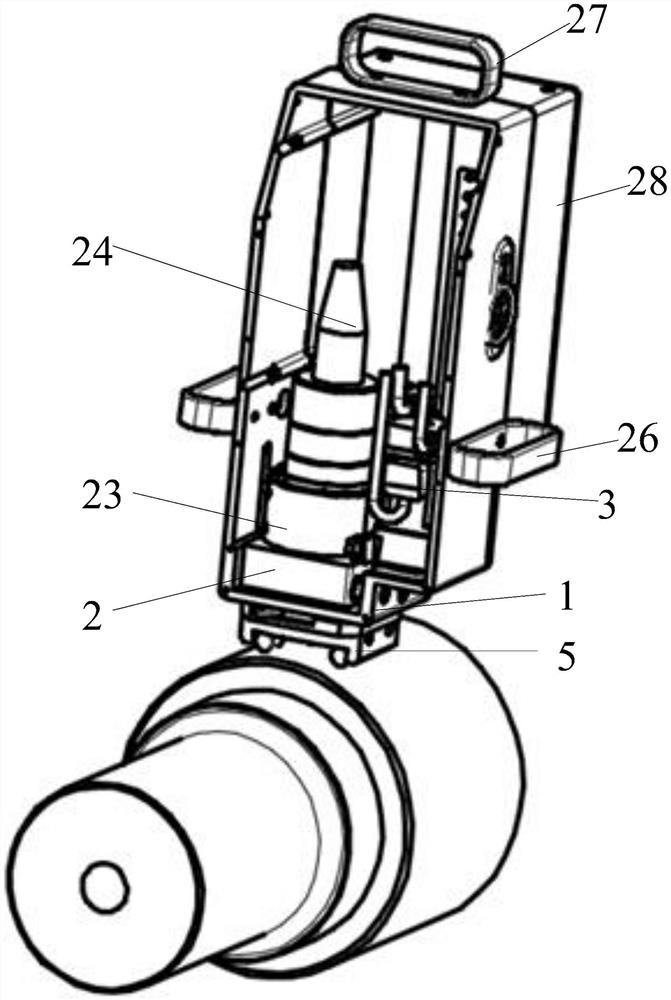

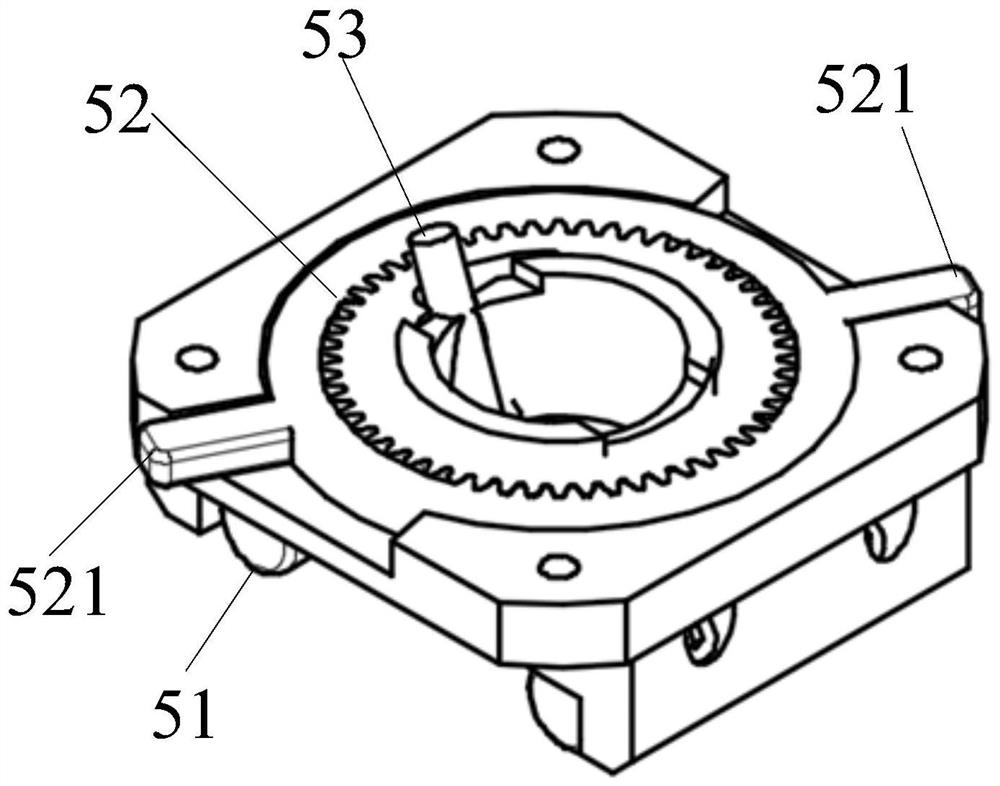

[0069] This embodiment is an embodiment of a micro-scratch detector on the surface. An oval groove is machined under the base as a detection window. The gear rotation mechanism is connected with the bottom of the base by bolts, and an endoscope lens is set on one side of it, which can roughly locate the scratch position, so that the detector can locate the scratch position. A sliding block moving device is installed inside the base, and an elliptical through hole is processed on the upper surface of the sliding block, and a through-hole plastic block is screwed on it. The probe is placed vertically in the plastic block, and the laser emitted by the probe can face the axis to be measured through the through hole. A pair of parallel through holes are processed in the side of the slide block, and linear bearings are arranged in them, and the cylindrical shaft passes through the linear bearings and is fixed on both sides of the base. An eccentric wheel transmission mechanism is ...

specific Embodiment 2

[0071] When the endoscope lens is positioned at the scratch in the horizontal position, after turning the gear to rotate the wrench, the detector can detect the scratch depth in the horizontal position.

[0072] The above-mentioned sensor probe can be a spectral confocal sensor or a laser sensor.

[0073] Considering the cost performance and accuracy requirements of the detection device, a spectral confocal lens sensor can be selected to measure the depth and width of scratches. The detection is quickly completed online in a non-contact manner, which improves the speed of scratch depth measurement, ensures the validity of the detection data, and solves the efficiency and accuracy problems caused by the current manual detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com