Method for measuring temperature of hearth of annealing furnace

A furnace temperature and measurement method technology, which is applied in the field of rolling technology, can solve problems such as control system fluctuations, instability, and inaccurate control of thermocouple temperature data, and achieve the effect of precise temperature rise and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

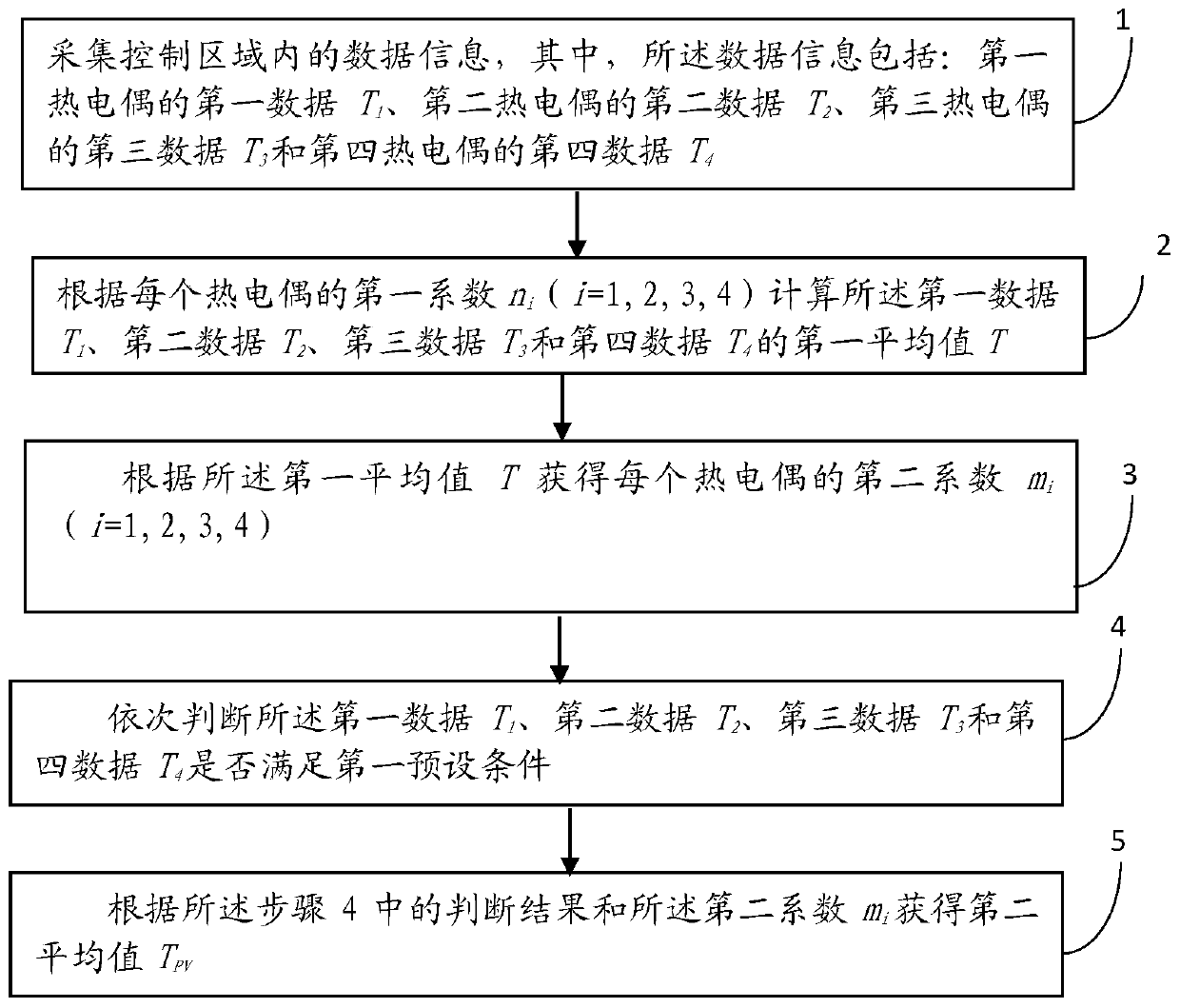

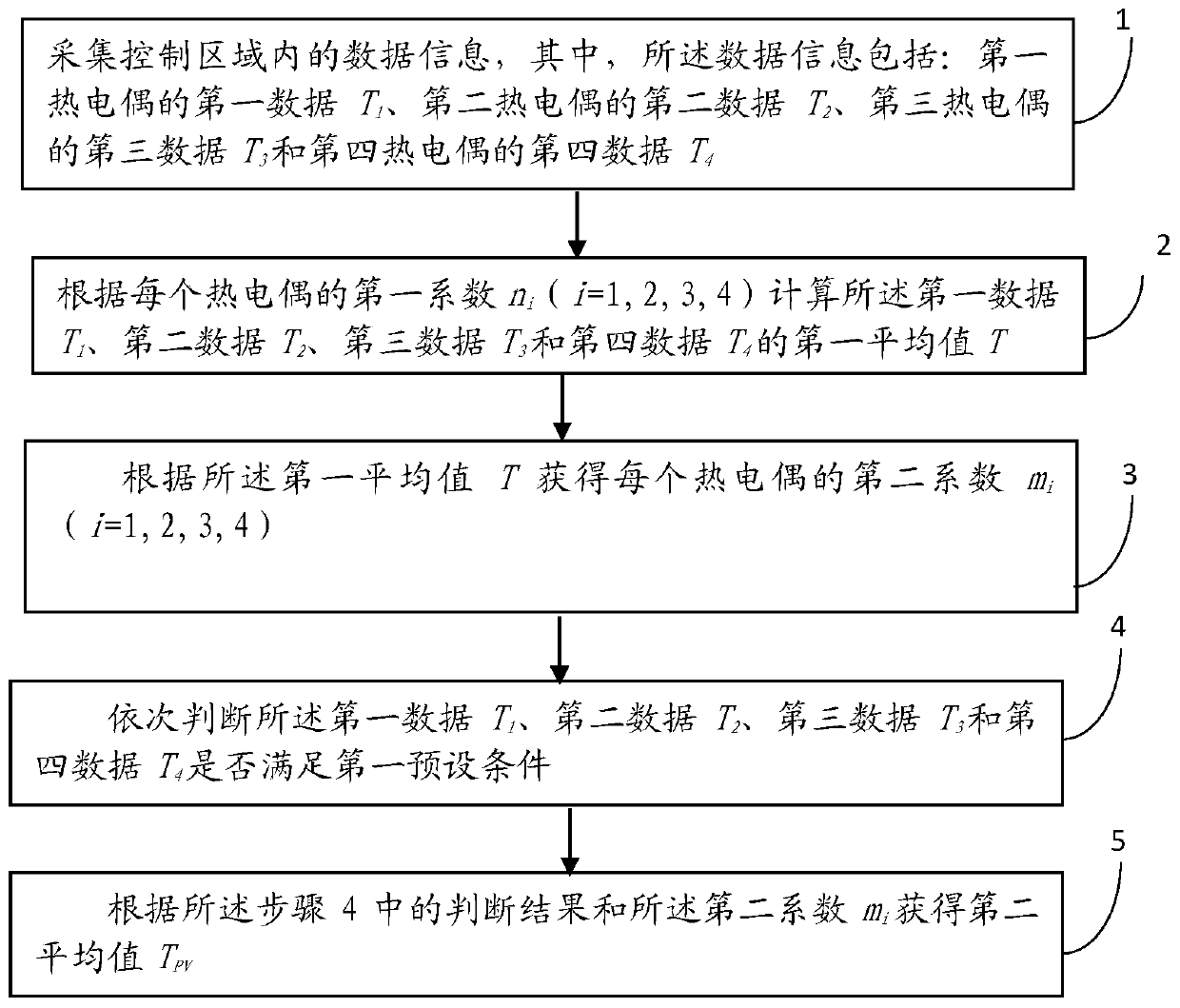

[0021] figure 1 It is a method for measuring the furnace temperature of an annealing furnace in the embodiment of the present invention, such as figure 1 As shown, the method includes:

[0022] Step 1: Collect data information in the control area, wherein the data information includes: the first data T of the first thermocouple 1 , the second data T of the second thermocouple 2 , the third data T of the third thermocouple 3 and the fourth data of the fourth thermocouple T 4 .

[0023] Step 2: According to the first coefficient n of each thermocouple i (i=1,2,3,4) calculate the first data T 1 , the second data T 2 , the third data T 3 and the fourth data T 4 The first mean T of .

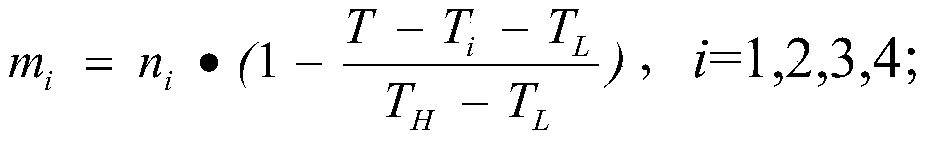

[0024] Further, in the step 2, the calculation formula of the first average value T is specifically: the first average value no 1 , n 2 , n 3 , n4 , are the first coefficient corresponding to each thermocouple respectively.

[0025] Further, in the step 2, it also includes: judging wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com