Variable liquid distributor and mounting method thereof

An installation method and liquid separator technology are applied in refrigeration and liquefaction, fluid circulation arrangements, mechanical equipment, etc., which can solve problems such as uneven heat dissipation of evaporators, affecting heat exchange capacity, and decline in heat exchange efficiency, and achieve the best air-conditioning performance Good, easy to process and assemble, and reduce flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

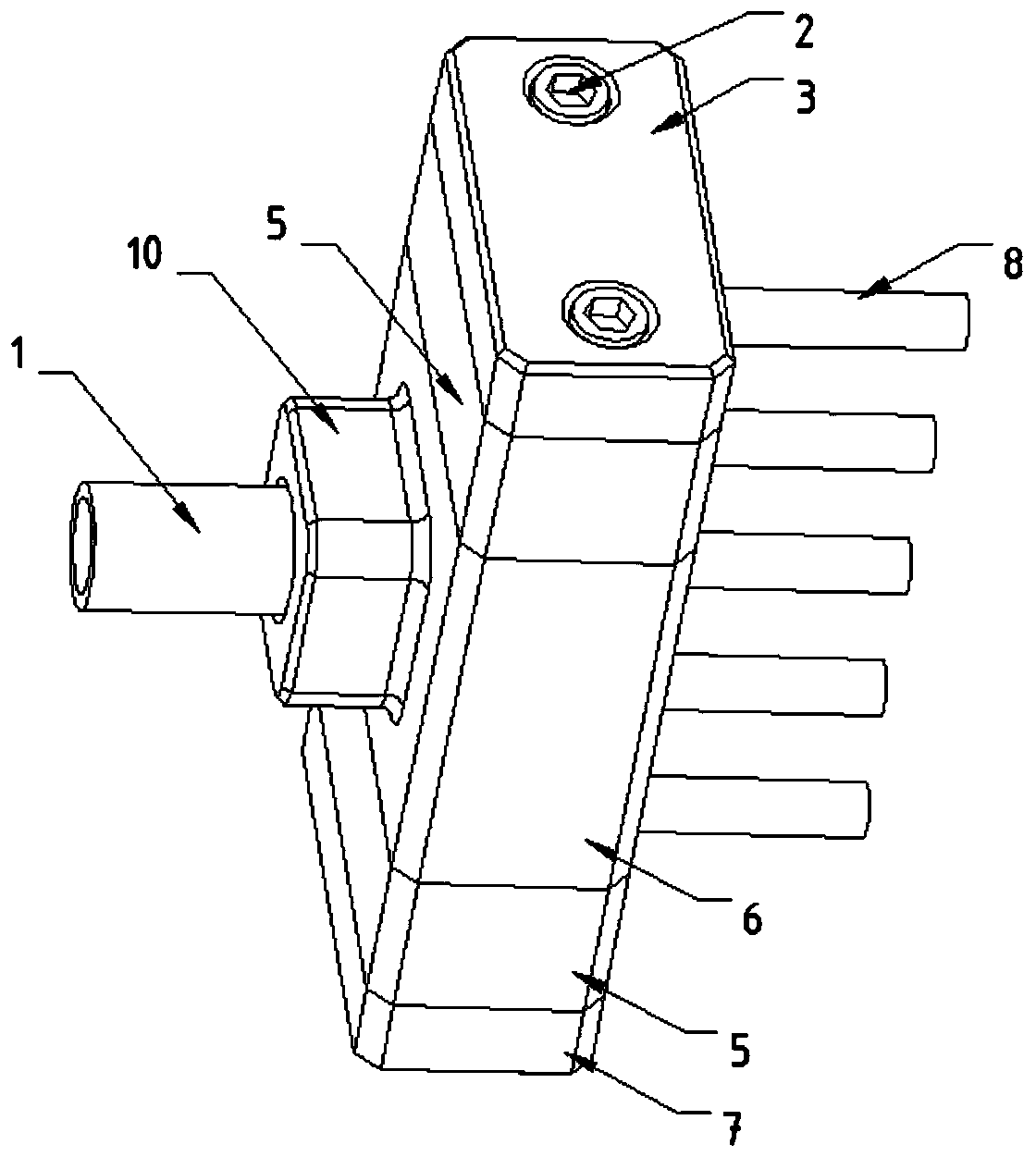

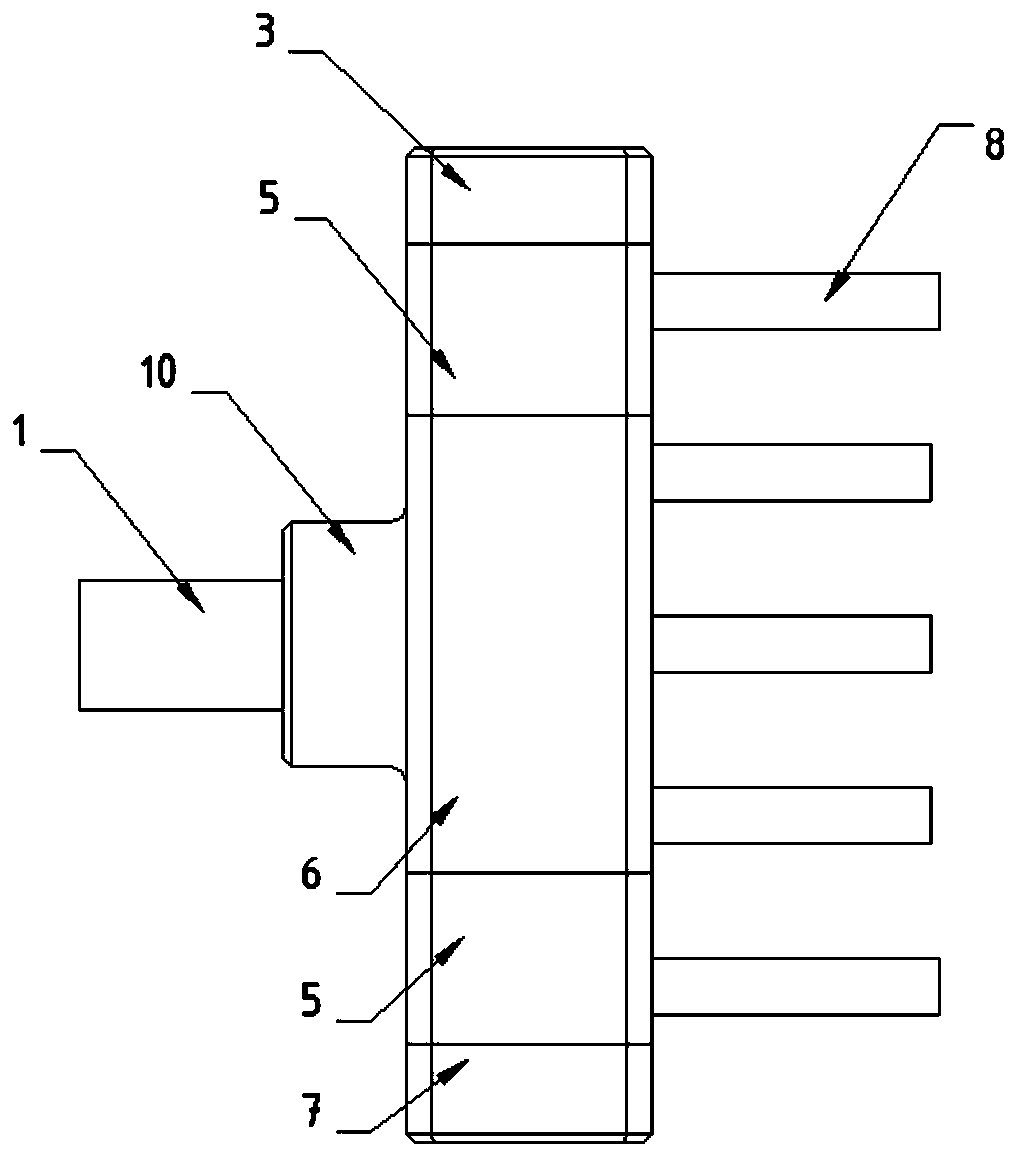

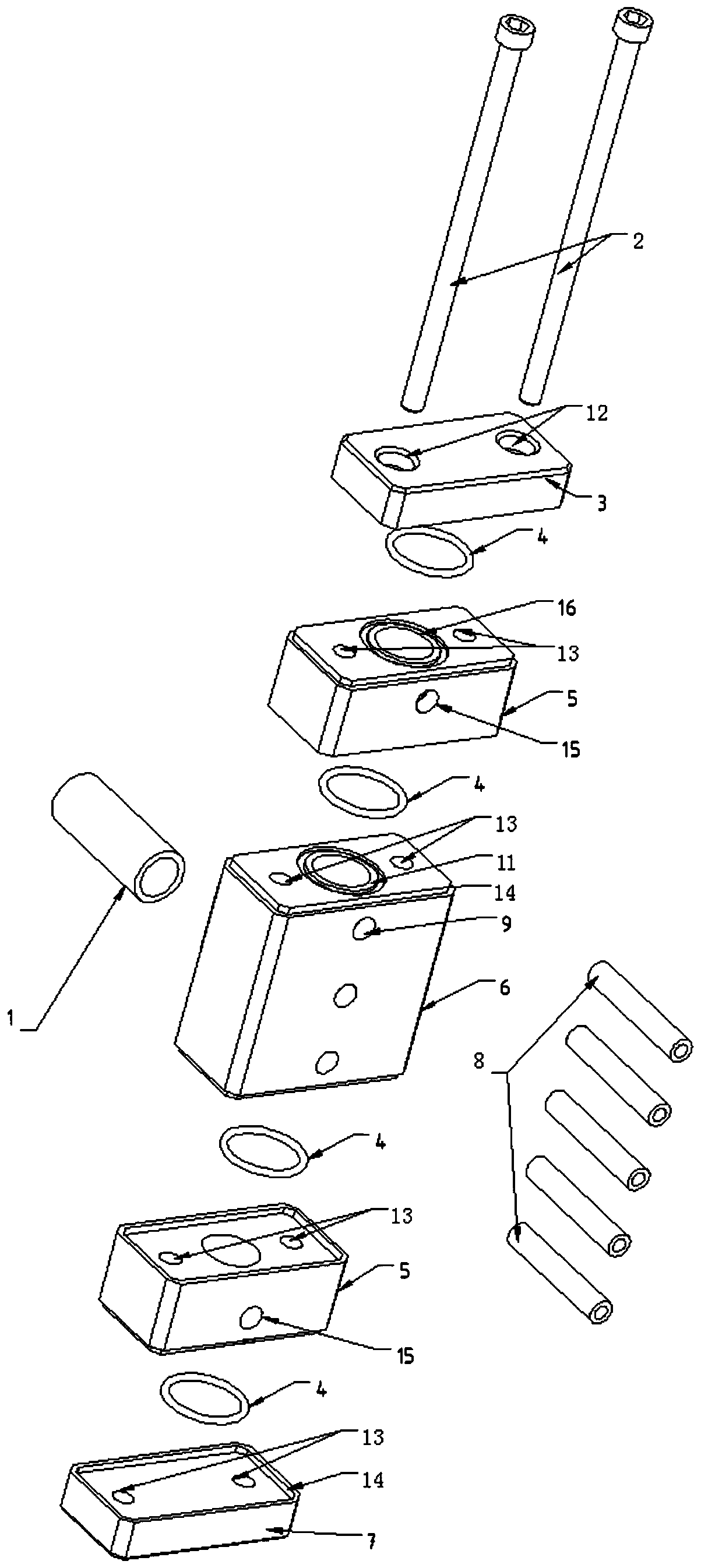

[0034] This embodiment provides a variable liquid separator, whose structure is detailed in the attached figure 1 , 2 As shown in and 3: it includes the upper seal cover 3, the main body 6 and the lower seal cover 7 which are penetrated and fixed by the hexagon socket bolt 2 from top to bottom, and also includes the O-ring 4, the second connecting pipe 1 and the first connecting pipe 8 The main body 6 is a cavity structure, and its side wall is provided with a plurality of first connecting pipe mounting holes 9 communicating with the cavity, and its other side wall is provided with a second connecting pipe mounting hole communicating with the cavity 10, its top end surface and bottom end surface are provided with the first O-shaped groove 11 that clamps the O-ring 4; the first connecting pipe 8 is provided with multiple ones, one end of which is inserted into the first connecting pipe installation hole 9, and the other One end is connected to the core body; one end of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com