A Fast Response Sensor Mechanism for Shift Sensing

A fast-response, sensor technology, applied to mechanical equipment, geared components, transmission control, etc., can solve the problems of unfavorable automatic clutch and response lag, and achieve the effect of efficient automatic clutch function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

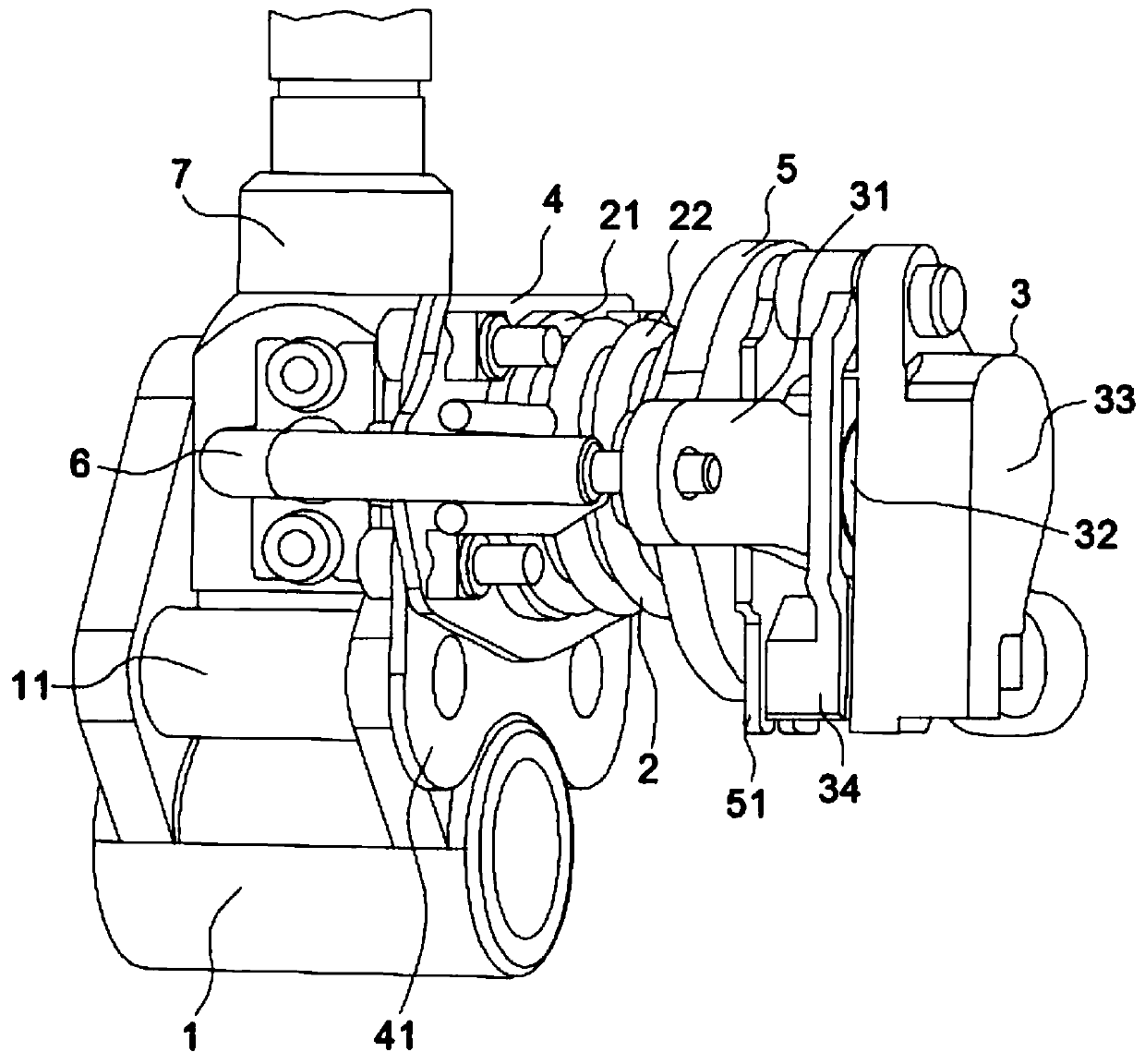

[0036] Such as figure 1 As shown, a fast-response shift sensing sensor mechanism mainly includes a rocker arm 1, a torsion spring mechanism 2, and a sensing mechanism 3;

[0037] Such as figure 1 As shown, the upper end of the rocker arm 1 is movably connected with the lower end of the shift handle 7, and a push rod 11 is respectively provided on the rocker arms 1 at the front and rear sides of the shift handle 7;

[0038] Such as figure 1 As shown, the right side of the rocker arm 1 is sequentially provided with a torsion spring mechanism 2 and a sensing mechanism 3 from left to right, and the torsion spring mechanism 2 and the sensing mechanism 3 are fixedly connected through the connecting plate 5;

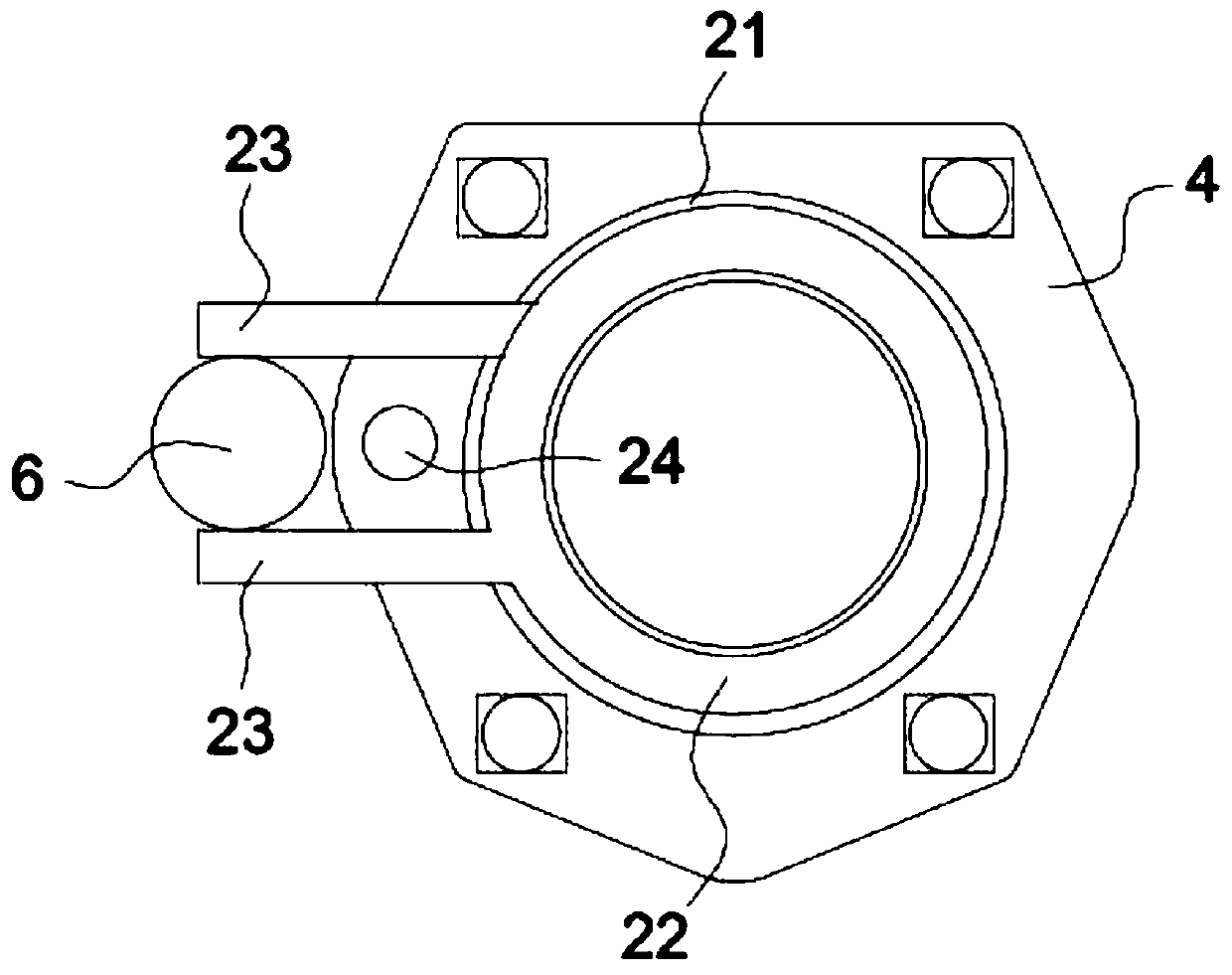

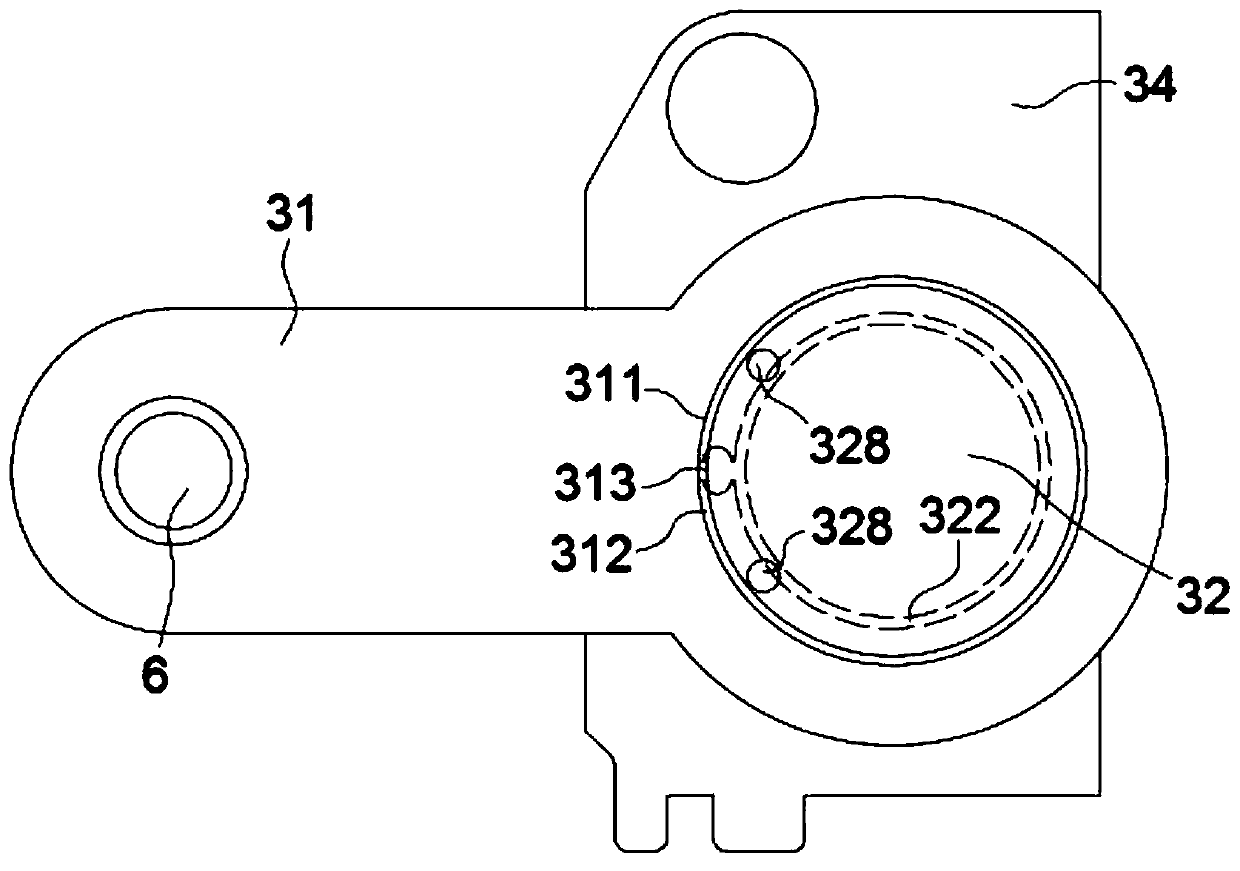

[0039] Such as figure 1 and 2 As shown, the torsion spring mechanism 2 includes a torsion spring shaft 21 and a torsion spring 22. The horizontal position of the torsion spring shaft 21 corresponds to the rotation axis position of the shift handle 7. The left side of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com