Gap-adjustable cotton slitter

A cotton opener and cotton technology, applied in the direction of opening and cleaning with toothed tools, can solve the problems of uneven feeding, affecting the construction period, time-consuming and laborious, etc., and achieve the effects of improving efficiency, preventing heat generation, and being practical.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

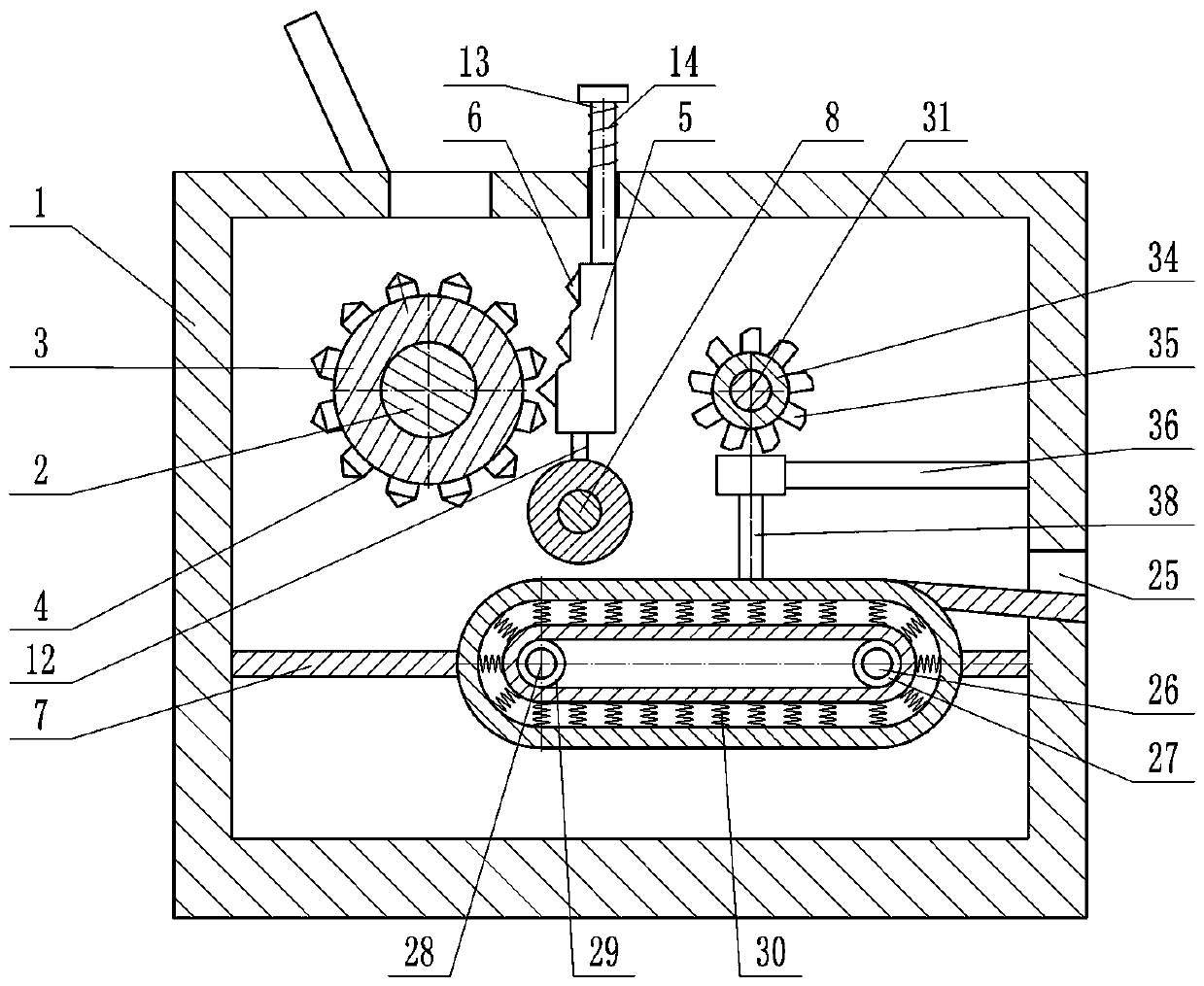

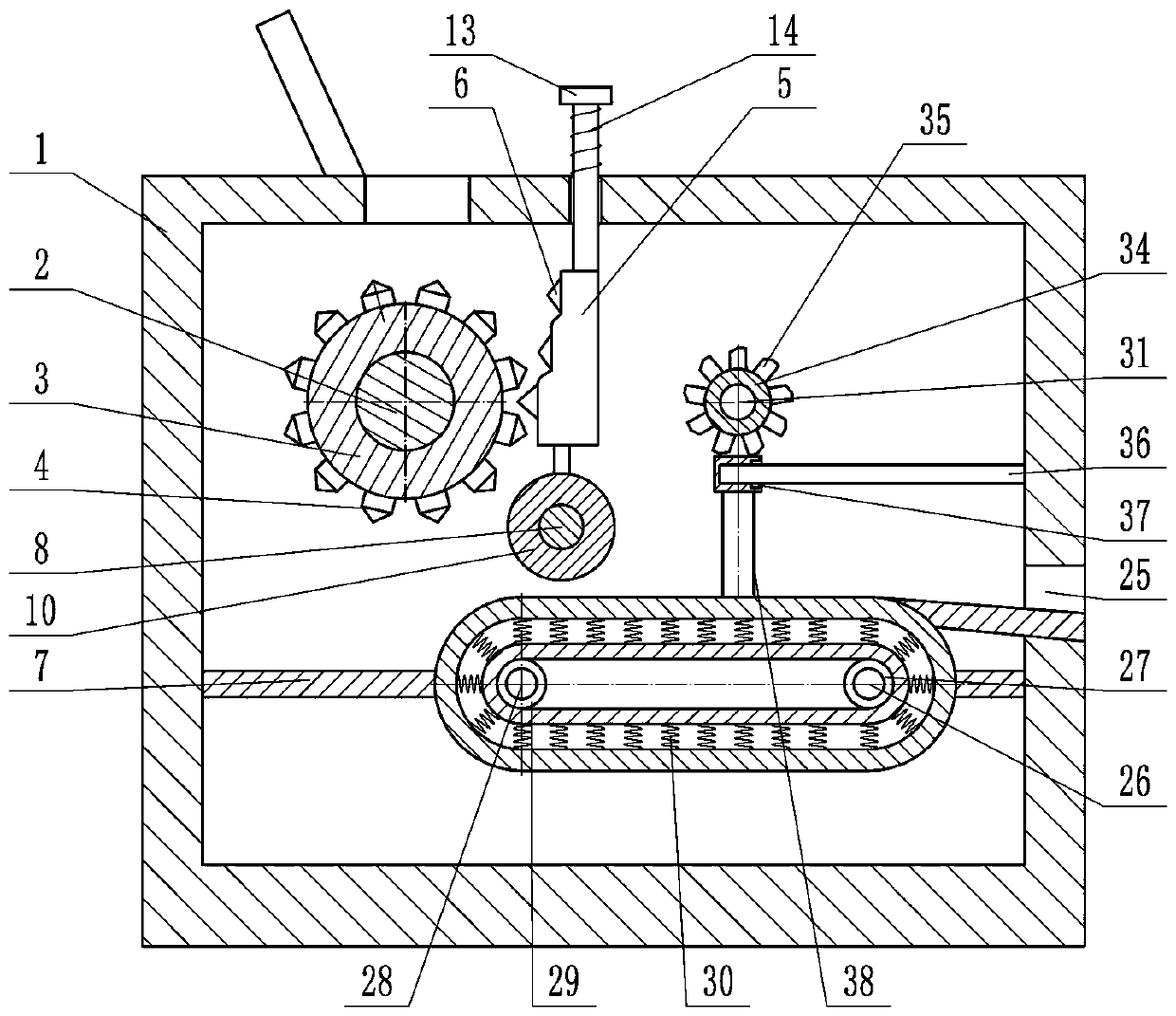

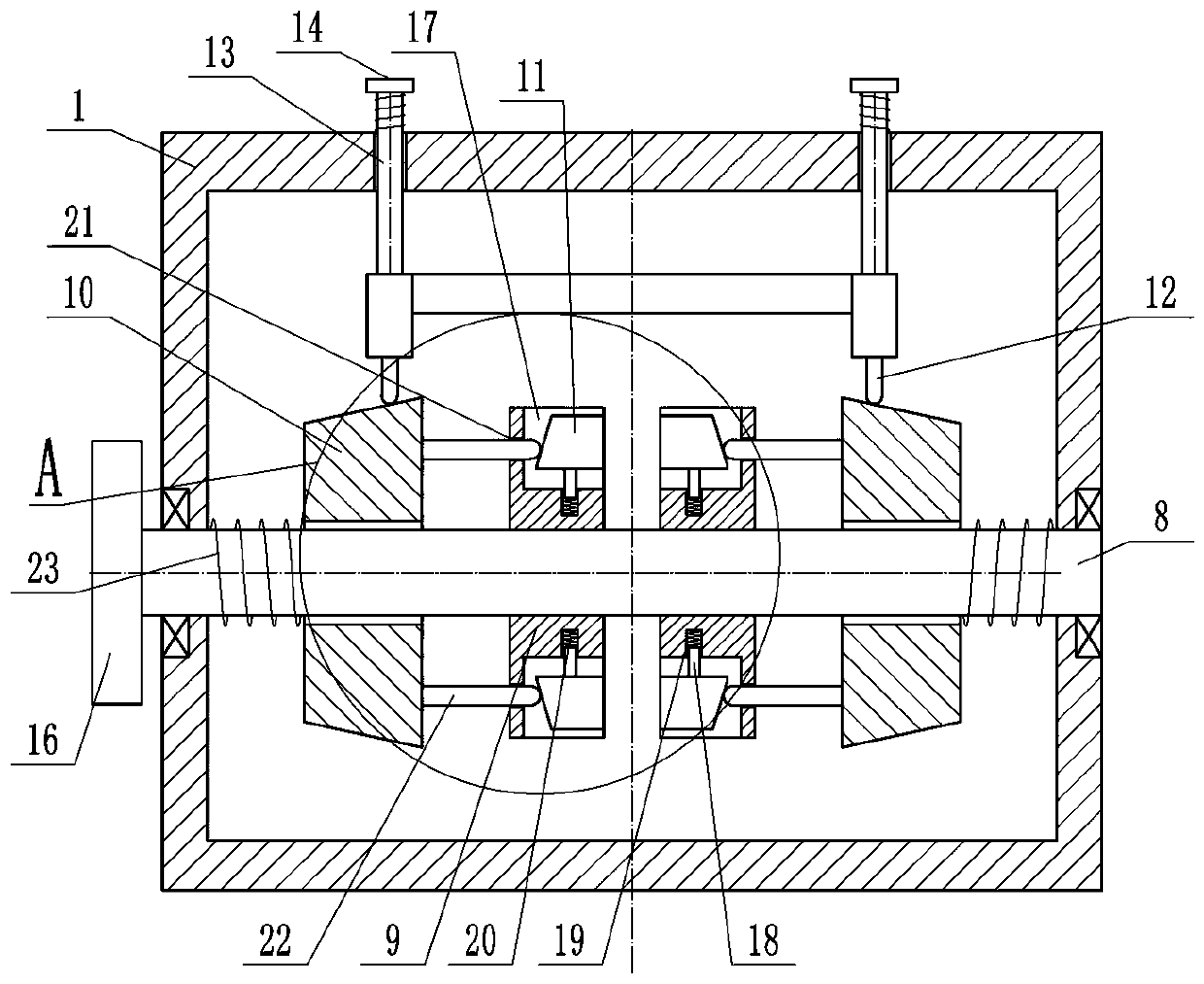

[0016] Depend on Figure 1 to Figure 8 Given, the present invention includes a box body 1 with an opening upward, and a first rotating shaft 2 that is placed horizontally in the front and rear direction and can rotate around its own axis is installed in the box body 1, and is set on the first rotating shaft 2 in the box body 1. There is a sleeve 3 that can rotate with the first rotating shaft 2. A plurality of fixed teeth 4 along the radial direction of the sleeve 3 are evenly distributed on the circumference of the sleeve 3. A front and rear teeth are installed on the box body 1 on the right side of the first rotating shaft 2 The horizontal plate 5 that is placed in the direction and can move up and down. The left end surface of the horizontal plate 5 is provided with a plurality of stepped surfaces that are wide at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com