A kind of preparation method of graphene zinc-containing epoxy anticorrosion coating

An anti-corrosion coating and graphene technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of incompatibility between aqueous solutions and epoxy resins, cumbersome processes, and restrict the application of graphene, so as to improve the anti-corrosion effect, Simplified preparation process, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

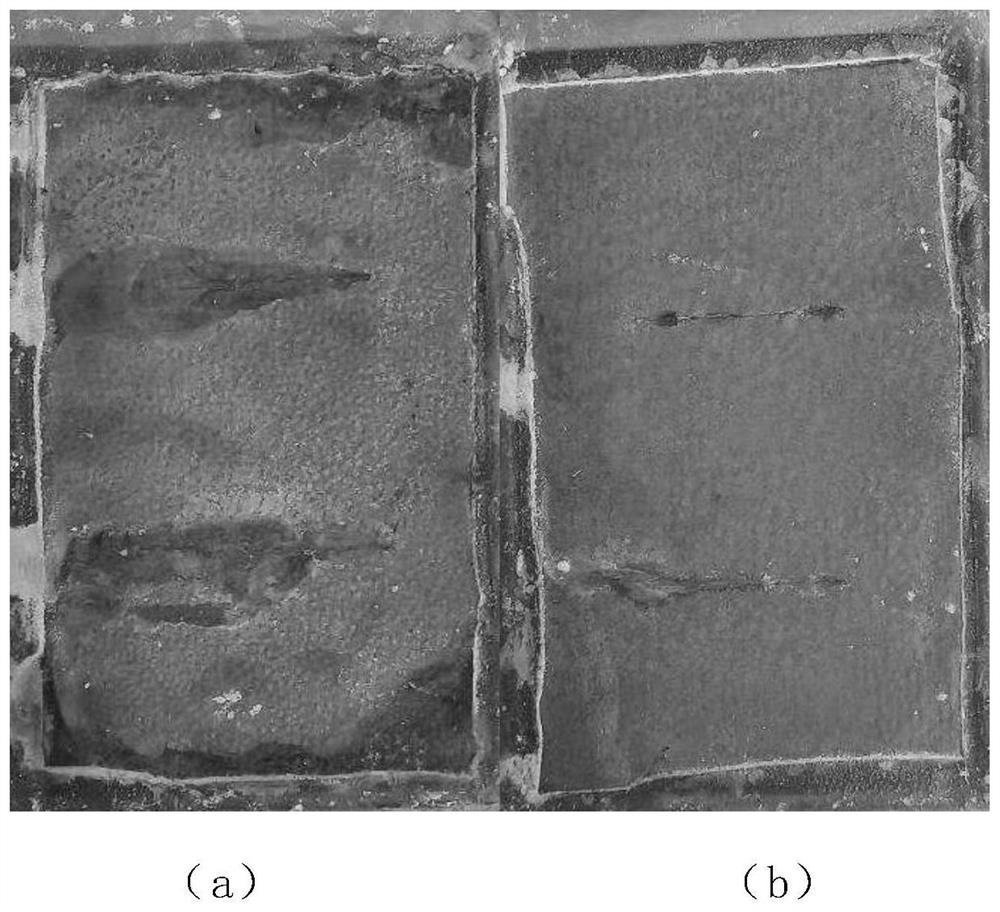

Image

Examples

preparation example Construction

[0031] A kind of preparation method of graphene zinc-containing epoxy anticorrosion coating of the present invention, comprises the following steps:

[0032] S1. Weigh graphene and deionized water into a reagent bottle to prepare a graphene dispersion with a concentration of 0.5 to 5 mg / mL;

[0033] S2. Put the reagent bottle into the ultrasonic cell pulverizer, set the mode to φ6, power 60-100%, time 15-60 minutes, rest for 2 seconds every 3 seconds or rest 4 seconds for every 1 second until there is no intermittent work. Coarsely dispersed (with fine particles but no large particles) graphene dispersion;

[0034] It is preferable to rest for two seconds every three seconds of work, and the diameter of the bottom of the ultrasonic rod is 6mm.

[0035] S3. Put the graphene dispersion prepared in step S2 into an ultrasonic cleaner for 30 to 90 minutes to obtain a finely dispersed (no granular) graphene slurry;

[0036] S4. Add a modified substance to the graphene slurry prepa...

Embodiment 1

[0046] (1) take by weighing 20mg graphene with electronic balance, put the graphene that weighs into the reagent bottle that has magneton;

[0047] (2) Add 20 mL of deionized water to the reagent bottle;

[0048](3) Put the reagent bottle in (2) into the ultrasonic cell pulverizer, the mode is set to φ6, the power is 90%, and the time is 30 minutes, wherein every three seconds of work is rested for two seconds to obtain a roughly dispersed graphene dispersion;

[0049] (4) Putting the graphene dispersion in (3) into an ultrasonic cleaner for ultrasonication, the time is 60 minutes;

[0050] (5) weigh 400mg sodium polystyrene sulfonate, add in the graphene dispersion;

[0051] (6) Stir on the magnetic stirrer until the graphene is evenly dispersed, and the dispersion is black and smooth, which means that the modified graphene dispersion has been prepared;

[0052] (8) Place the graphene-modified dispersion liquid and the epoxy coating A component with 20% zinc content in a ce...

Embodiment 2

[0057] (1) take by weighing 30mg graphene with electronic balance, put the graphene that weighs into the reagent bottle that has magneton;

[0058] (2) Add 20 mL of deionized water to the reagent bottle;

[0059] (3) Put the reagent bottle in (2) into the ultrasonic cell pulverizer, the mode is set to φ6, the power is 80%, and the time is 45 minutes, wherein every three seconds of work is rested for two seconds, and a roughly dispersed graphene dispersion is obtained.

[0060] (4) Graphene dispersion in (3) is put into ultrasonic cleaner and carries out ultrasonic, time is 60 minutes (5) weigh 450mg sodium polystyrene sulfonate, add in the graphene dispersion;

[0061] (6) Stir on the magnetic stirrer until the graphene is evenly dispersed, and the dispersion is black and smooth, which means that the modified graphene dispersion has been prepared;

[0062] (8) Component A of the epoxy zinc-rich primer of the graphene-modified dispersion and 40% zinc content is placed in a cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com