Rotary centre

A tip and thimble technology, which is applied in the direction of tailstock/top, turning equipment, tool holder accessories, etc., can solve the problems of low production efficiency and achieve the effect of increasing connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

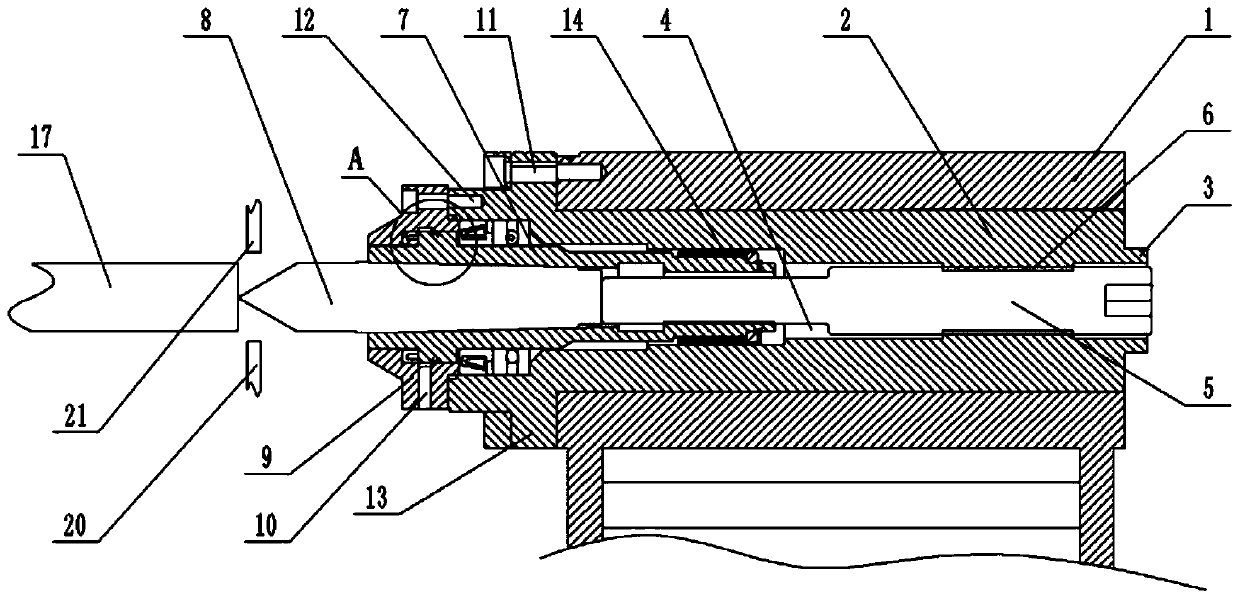

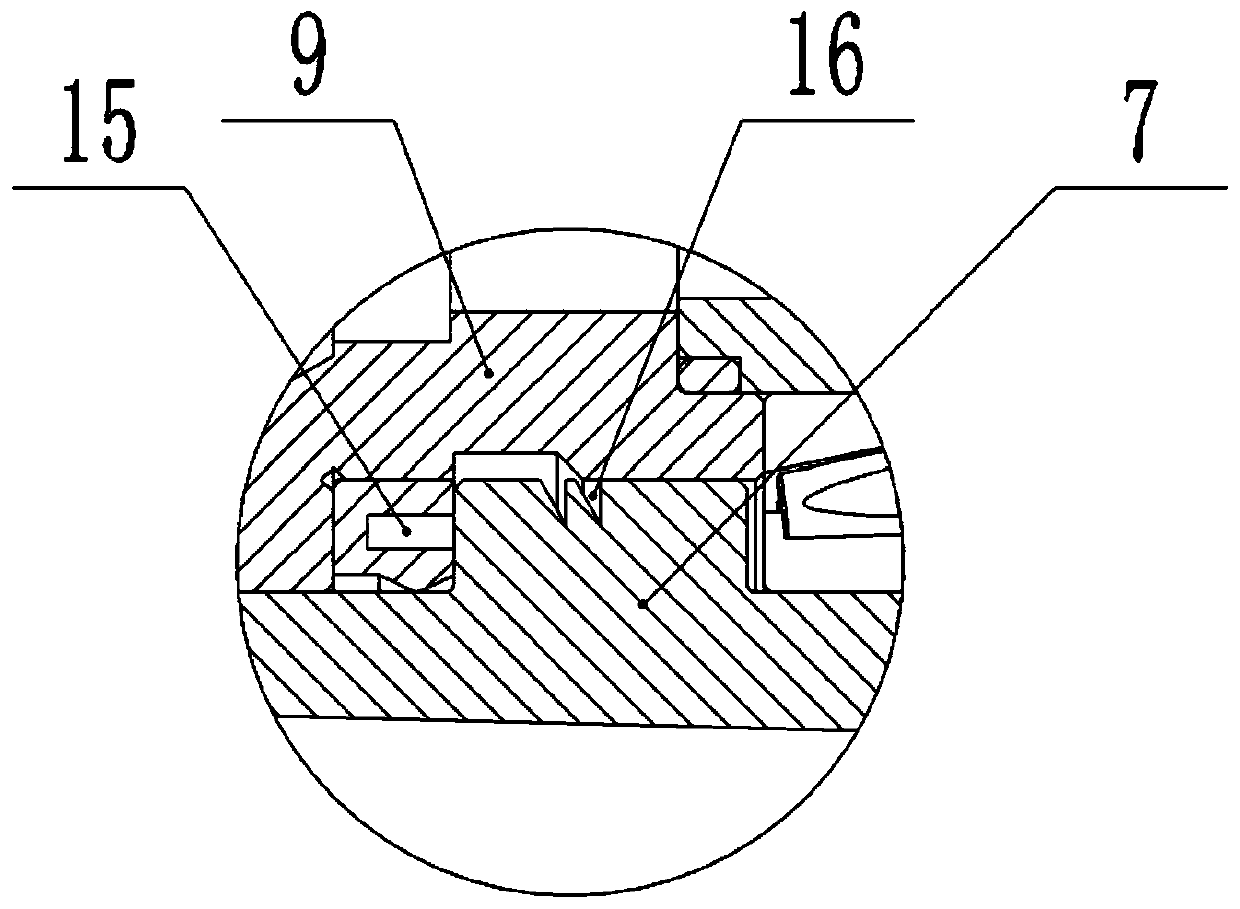

[0036] Such as figure 1 As shown, a rotating top includes a sleeve 2, and the sleeve 2 sequentially includes a mounting hole, a bearing hole and an eccentric hole 4 from left to right, and the mounting hole and the bearing hole are coaxially arranged and are coaxially arranged with the sleeve 2 The eccentric hole 4 is arranged eccentrically relative to the sleeve 2 . The left part of the sleeve 2 is fixed with an annular connection plate 13, and in order to ensure assembly stability, the connection plate 13 and the sleeve 2 are integrally formed. There are several arc-shaped holes uniformly distributed along the circumferential direction on the connection plate 13. When the sleeve 2 is installed on the tailstock 1 of the machine tool, the sleeve 2 is inserted into the tailstock 1, and the right end surface of the connection plate 13 is offset against the tailstock 1. The second bolt 11 is passed through the arc-shaped hole and screwed into the tailstock 1 to realize the fixin...

Embodiment 2

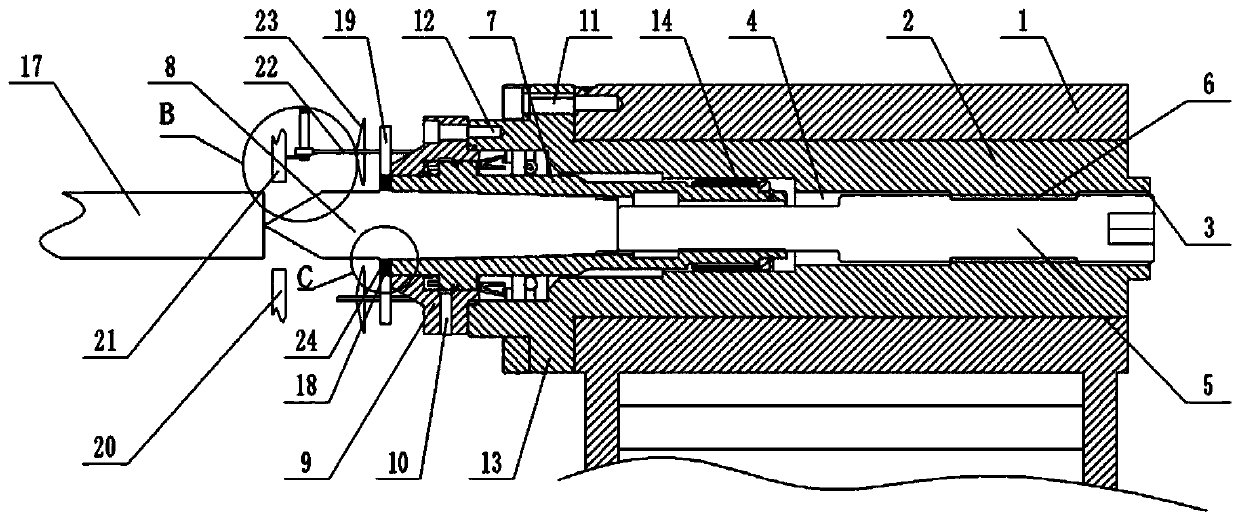

[0046] Compared with embodiment 1, present embodiment, as image 3 As shown, the dust-proof structure also includes a driving gear 18 fixed on the mandrel 7 away from the left end of the ejector rod 5. The inner diameter of the central hole of the driving gear 18 is greater than the outer diameter of the thimble 8, and the sealing cover 9 is rotatably connected with a rotating rod 22. The driven gear 19 meshed with the driving gear 18 is fixed on the rod 22, and several blades 23 are evenly distributed along the circumferential direction on the rotating rod 22. Figure 5 As shown, the inner wall of the central hole of the driving gear 18 is fixed with an annular sealing washer 24 , the inner wall of the sealing washer 24 is opposed to the thimble 8 , and a plurality of rotating rods 22 are provided and evenly distributed along the circumferential direction of the sealing cover 9 .

[0047] combine Figure 4 As shown, the left end of the rotary rod 22 on the top of the seal co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com