Cultivation house excrement real-time separating, collecting and conveying system based on slatted floor

A slatted floor and real-time separation technology, which is applied in the field of animal husbandry, can solve problems such as difficulty in ensuring dryness and cleanliness of pens, loss of nutrients in manure, and deterioration of the environment in the pen, so as to reduce the chance of bacterial growth and virus transmission, and reduce nutrition. Element loss rate, the effect of avoiding humidity in the house

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

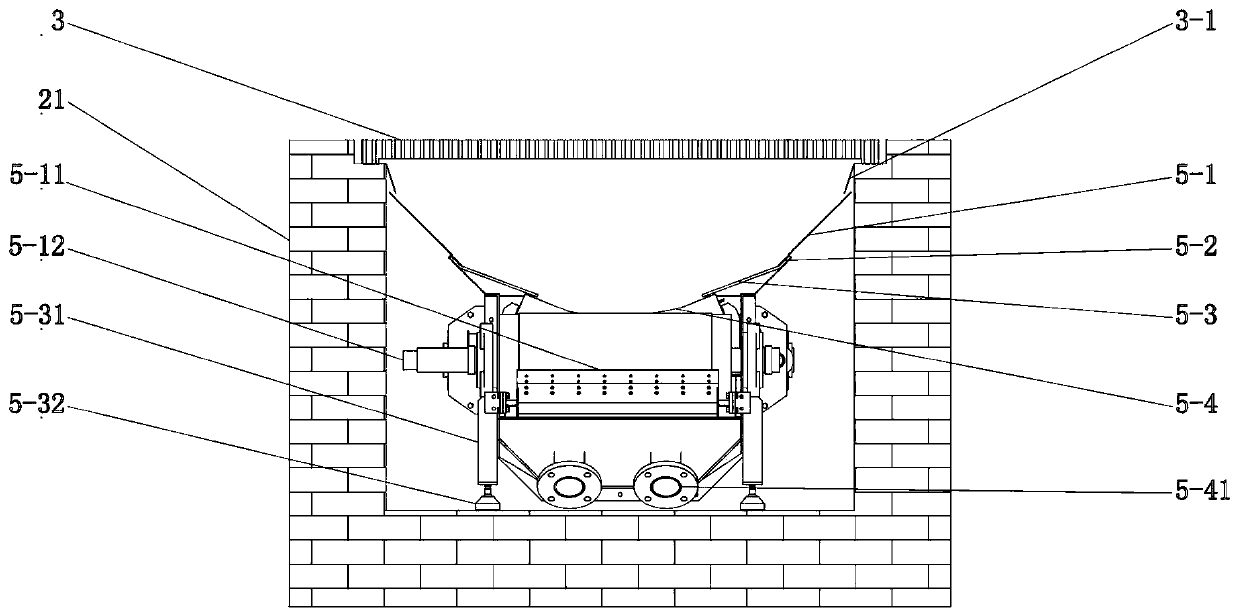

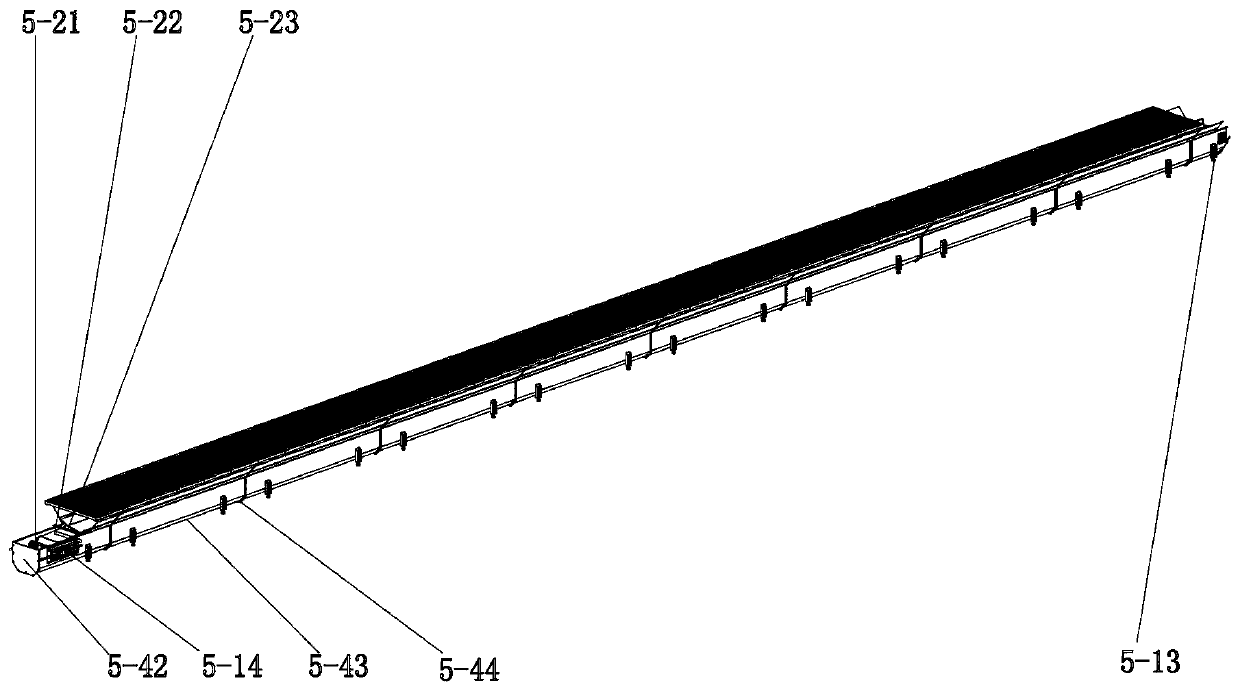

[0034] A real-time separation, collection and transportation system for feces and sewage in breeding houses based on slatted floors, including: breeding house floors, dry manure storage tanks, urine storage tanks, slatted floors, screw conveyors, separation conveyors, fences, flushing water tanks, Centrifugal pumps, manure collection tanks, slat floor cleaners, power control cabinets and gas monitoring boxes for control and regulation.

[0035]The ground of the breeding house is equipped with at least a manure collection tank, and the upper part of the manure collection tank is tiled with a slatted floor, so that the dry manure and urine on the floor can fall into the manure collection tank, and at le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com